At its core, ceramic pressing is a multi-stage manufacturing process that transforms a specialized ceramic powder into a dense, solid component. This involves preparing the powder into a flowable form, pressing it into a preliminary shape called a "green body," and then applying heat and pressure in a furnace to fuse the particles together through a process called sintering.

The success of ceramic pressing hinges less on the individual steps and more on the meticulous control of key variables. The core challenge is managing the material's transformation to achieve precise final dimensions, desired aesthetics, and optimal physical properties without introducing flaws.

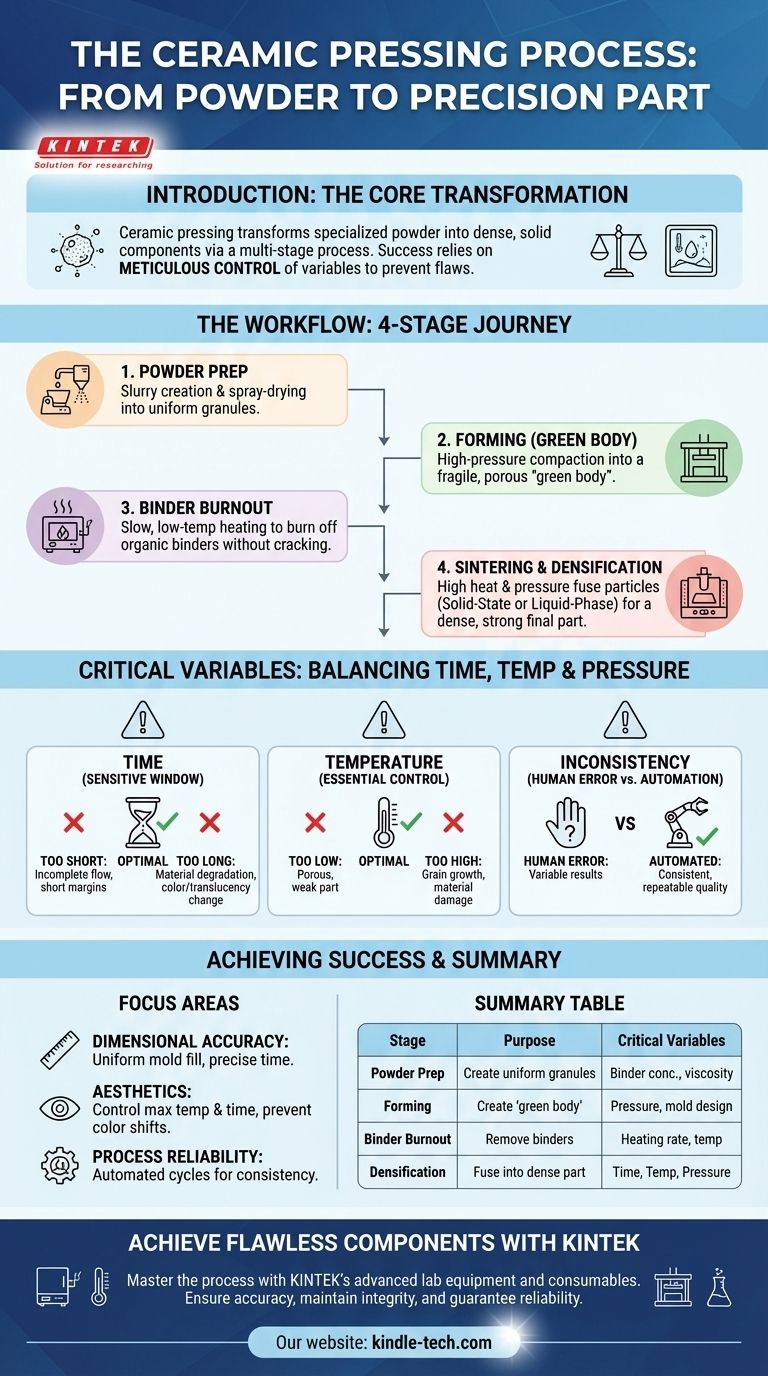

The Ceramic Pressing Workflow: From Powder to Part

The journey from a raw powder to a finished ceramic component is a precise, sequential process. Each step builds upon the last, and failure at any stage can compromise the final result.

Step 1: Preparing the Ceramic Powder

First, the raw, unfired ceramic powder is mixed with water, a binder, and a deflocculant (a substance that prevents clumping). This creates a uniform, liquid mixture known as a slurry.

This slurry is then spray-dried. The process atomizes the slurry into a heated chamber, instantly evaporating the liquid and forming small, uniform, and spherical granules. These granules are ideal for ensuring the mold fills evenly.

Step 2: Forming the "Green Body"

The spray-dried powder is then placed into a mold. Under high pressure, the powder is compacted into a solid, albeit fragile, shape.

This initial, un-sintered part is called a "green body." While it holds its shape, it has very low mechanical strength and is highly porous.

Step 3: Binder Burnout

Before the final fusion, the green body is heated at a relatively low temperature. The purpose of this stage is to carefully burn off the organic binder that was added in Step 1.

This must be done slowly to allow the resulting gases to escape without cracking or damaging the fragile part.

Step 4: Sintering and Densification

Sintering is the critical high-temperature step where the ceramic particles fuse together to form a dense, strong final part. The green body is brought to a pressing furnace, where an ingot and plunger may be used to apply pressure while the temperature is raised.

This densification primarily occurs through two mechanisms:

- Solid-State Sintering: Used for materials like zirconia, where atoms migrate between particles via diffusion, closing the gaps between them.

- Liquid-Phase Sintering: Used for harder-to-sinter materials like silicon carbide. Additives in the powder melt, creating a liquid that pulls particles together through capillary forces, accelerating densification.

Understanding the Trade-offs and Critical Variables

The quality of a pressed ceramic is not guaranteed by simply following the steps. It is dictated by the precise control of time, temperature, and pressure. Deviations can lead to irreversible defects.

The Critical Role of Pressing Time

Time is arguably the most sensitive variable in the final pressing stage. The window for a perfect press is often narrow.

- Time Too Short: If the press cycle is too brief, the material may not have enough time to flow and completely fill the mold. In a dental application, this results in defects like short margins.

- Time Too Long: Excessive time under heat and pressure can cause material degradation. This can manifest as unwanted changes in color or translucency, or even alter the material's core physical properties.

The Impact of Temperature

Proper temperature control during both binder burnout and final sintering is essential. If the temperature is too low, sintering will be incomplete, leaving the final part porous and weak.

Conversely, if the temperature is too high or applied too quickly, it can cause grain growth or material damage, compromising strength and aesthetics.

The Consequence of Inconsistency

Different ceramic materials have unique requirements. For example, with lithium disilicate, a common dental ceramic, an excessive press time can cause an undesirable reaction layer to form on the surface.

This is why automated press furnaces are often used. They ensure that the optimal time and temperature profiles are repeated with absolute consistency, minimizing the risk of defects caused by human error.

Achieving a Successful Press

Understanding these principles allows you to troubleshoot issues and optimize your process for specific outcomes.

- If your primary focus is dimensional accuracy: Ensure the powder is properly prepared for uniform mold filling and pay strict attention to press time to avoid incomplete flow and short margins.

- If your primary focus is aesthetics: Meticulously control the maximum temperature and the duration of the press cycle to prevent color shifts, changes in translucency, or surface reactions.

- If your primary focus is process reliability: Rely on automated equipment with pre-programmed cycles for specific materials to eliminate variables and ensure consistent, high-quality results.

Mastering the ceramic pressing process is a matter of transforming it from a simple procedure into a controlled science.

Summary Table:

| Stage | Key Process | Purpose | Critical Variables |

|---|---|---|---|

| 1. Powder Prep | Spray Drying | Create uniform, flowable granules | Binder concentration, slurry viscosity |

| 2. Forming | Pressing | Create a 'green body' shape | Pressure, mold design |

| 3. Binder Burnout | Low-Temp Heating | Remove organic binders | Heating rate, temperature |

| 4. Densification | Sintering | Fuse particles into a dense, strong part | Time, Temperature, Pressure |

Achieve flawless ceramic components with KINTEK.

Mastering the ceramic pressing process requires precision and consistency at every stage. KINTEK specializes in the advanced lab equipment and consumables needed for reliable results, from powder preparation to final sintering.

Our solutions help you:

- Ensure Dimensional Accuracy: Achieve perfect mold fill and avoid defects like short margins.

- Maintain Material Integrity: Control time and temperature to preserve aesthetics and physical properties.

- Guarantee Process Reliability: Leverage automated systems for repeatable, high-quality outcomes.

Let us provide the tools and expertise for your laboratory's success. Contact KINTEK today to discuss your specific ceramic pressing needs.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is XRF sample preparation? Achieve Accurate and Reliable Elemental Analysis

- What is the role of a laboratory hydraulic press in LLZO pellet preparation? Enhance Ionic Conductivity via Cold Pressing

- What is uniaxial pressing of ceramics? A Guide to High-Volume Production of Simple Shapes

- How does a manual press work? Unlock Powerful Force Without Electricity

- What is the main maintenance need of hydraulic systems? Master Fluid Management to Prevent Costly Failures

- What are the examples where hydraulic press is applicable? From Sample Prep to Industrial Manufacturing

- What is the purpose of a hydraulic press? Generate Immense Force for Shaping, Crushing, and Compacting

- Why are high-precision laboratory hydraulic presses used for testing PHBV? Ensure Flawless Sample Preparation