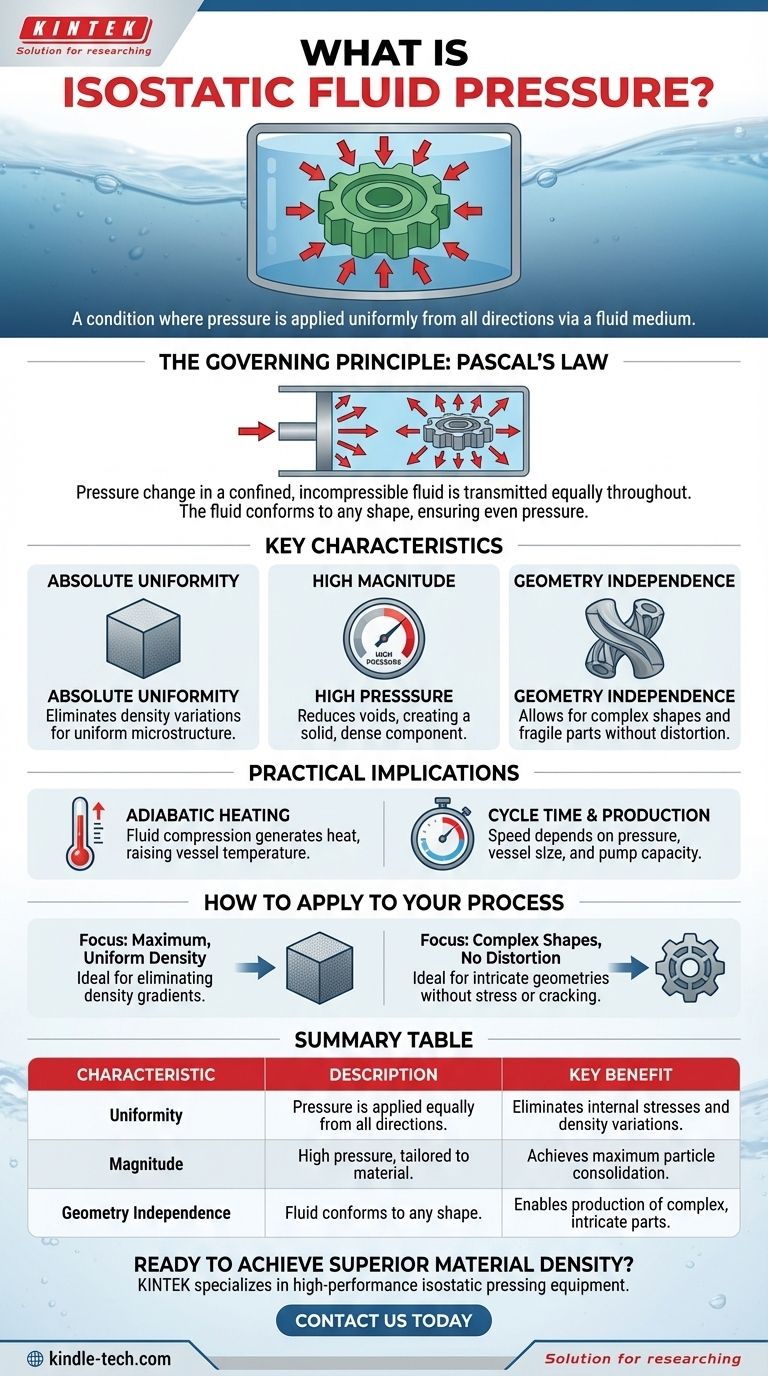

In the context of isostatic pressing, the term "isostatic pressure" does not refer to a single, fixed value. Instead, it describes a condition where pressure is applied uniformly from all directions simultaneously. This is achieved by using a fluid as the pressure-transmitting medium, ensuring that every surface of the object being pressed experiences the exact same force.

The defining characteristic of isostatic fluid pressure is its perfect uniformity. This principle allows for the consolidation of powders or the processing of materials into dense, uniform solids without the internal stresses, cracks, or distortions typical of directional pressing methods.

The Governing Principle: Why Isostatic Pressure is Uniform

The behavior of isostatic fluid pressure is rooted in a fundamental law of physics. Understanding this principle is key to grasping why this manufacturing technique is so effective for specific applications.

Pascal's Law in Action

Isostatic pressure is a direct application of Pascal's Law. This principle states that a pressure change at any point in a confined, incompressible fluid is transmitted equally throughout the fluid.

When a pump increases the pressure of the fluid in a sealed vessel, that pressure is exerted on every single point within the fluid and on all surfaces of the container walls—and the part inside—with equal magnitude.

The Role of the Fluid Medium

The fluid (typically water or oil) acts as the perfect medium for transmitting this force. Unlike a solid piston, which applies force in one direction, a fluid has no shear strength and conforms perfectly to any shape.

This ensures that even the most complex or intricate parts are pressurized evenly across their entire surface area.

Key Characteristics in Application

The theoretical principle of uniform pressure translates into several critical advantages during the manufacturing process.

Absolute Uniformity

The primary benefit is the elimination of pressure gradients. In conventional (uniaxial) pressing, friction between the powder and the die walls creates significant density variations within the part.

Isostatic pressure sidesteps this issue entirely, resulting in a final product with highly uniform density and microstructure.

High Magnitude

While not a single value, the applied pressures are typically very high. The exact level depends on the material and desired final density.

This high pressure reduces the voids between powder particles, creating a solid, dense component.

Independence from Part Geometry

Because the pressure is applied by a fluid, it is not limited by the part's shape. This allows for the creation of complex geometries that would be impossible to form with rigid dies.

It also means that fragile green parts can be densified without the risk of fracture from uneven, directional forces.

Practical Implications and Constraints

While powerful, the isostatic process is governed by real-world factors that influence its application and efficiency.

Adiabatic Heating

Compressing the fluid medium generates heat. This adiabatic compression can cause the temperature inside the pressure vessel to rise, sometimes by as much as 25°C.

While often minor, this temperature increase must be accounted for with sensitive materials. In some systems, the pressure chamber can be actively cooled to mitigate this effect.

Cycle Time and Production Rate

The overall speed of the process is not instantaneous. Production rates depend on several factors.

These include the final pressure required, the size of the pressure vessel, the capacity of the high-pressure pumps, and the level of automation for loading and unloading parts. A full cycle can be as fast as one minute, but this varies significantly.

How to Apply This to Your Process

Choosing a manufacturing process requires matching its core strengths to your primary objective.

- If your primary focus is achieving maximum, uniform density: Isostatic pressing is an ideal choice because its uniform pressure eliminates the density gradients common in other methods.

- If your primary focus is creating complex shapes without distortion: The use of a fluid medium allows pressure to conform perfectly to any geometry, preventing the stress and cracking that directional pressing can cause.

Ultimately, isostatic fluid pressure provides a powerful method for creating superior quality components by applying force with perfect uniformity.

Summary Table:

| Characteristic | Description | Key Benefit |

|---|---|---|

| Uniformity | Pressure is applied equally from all directions via a fluid medium. | Eliminates internal stresses and density variations. |

| Magnitude | Typically high pressure, tailored to material and desired density. | Achieves maximum particle consolidation and density. |

| Geometry Independence | Fluid conforms to any shape, unlike rigid dies. | Enables production of complex, intricate parts without distortion. |

Ready to achieve superior material density and complex geometries in your lab?

KINTEK specializes in high-performance isostatic pressing equipment and consumables, designed to deliver the perfect uniformity your laboratory demands. Our solutions help you eliminate density gradients and produce intricate parts with precision.

Contact us today to discuss how our expertise can enhance your manufacturing process!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process