The primary rating for a hydraulic press is not its internal fluid pressure, but its maximum achievable force, measured in tonnage. While the system operates on hydraulic pressure (measured in PSI or bar), the specification that defines the press's capability is the total output force it can exert on the workpiece. This tonnage is a product of that internal pressure and the surface area of the main hydraulic cylinder.

A common point of confusion is mistaking the system's hydraulic pressure (PSI) for the machine's overall rating. The key specification to understand and compare is tonnage, which represents the total force the press can apply.

Deconstructing Hydraulic Press Ratings

To properly select and utilize a hydraulic press, it's essential to understand the difference between the pressure within its system and the force it delivers. These two concepts are related but distinct.

The Critical Distinction: Force vs. Pressure

Pressure is the amount of force exerted per unit of area. In a hydraulic press, this is the pressure of the hydraulic fluid generated by the pump, typically measured in Pounds per Square Inch (PSI).

Force, on the other hand, is the total output delivered by the press. This is what performs the work, like shaping metal or compressing material, and it is almost always measured in tons.

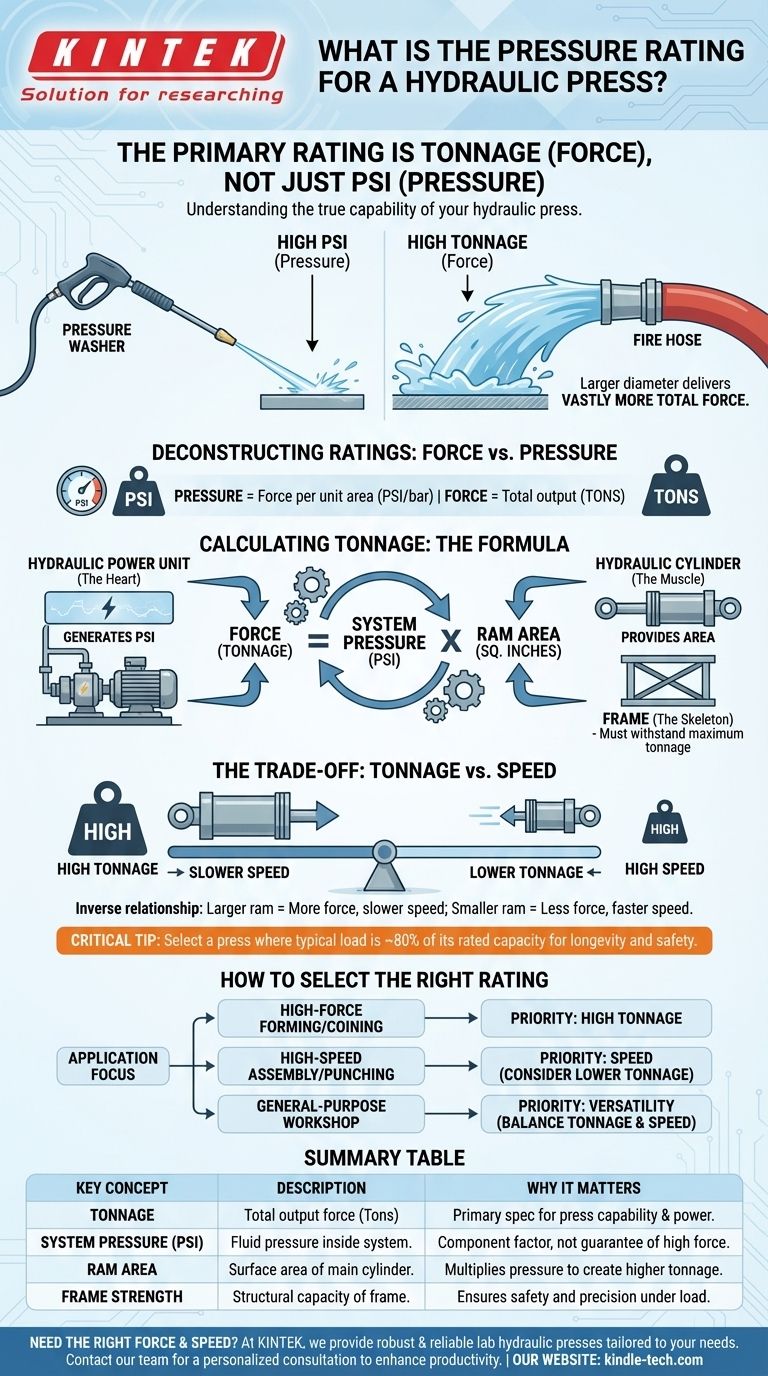

Think of it as the difference between a pressure washer nozzle and a fire hose. Both can have high internal water pressure (PSI), but the much larger diameter of the fire hose delivers vastly more total force.

How Tonnage is Calculated

The immense force of a hydraulic press comes from a simple principle: Pascal's Law. The final tonnage is determined by a clear formula.

- Force (Tonnage) = System Pressure (PSI) x Ram Area (Square Inches)

This relationship shows that you can achieve high tonnage in two ways: by increasing the system's fluid pressure or by increasing the size of the ram.

Key Components That Determine Performance

The tonnage rating isn't an arbitrary number; it's a direct result of the press's core engineering components working together.

The Hydraulic Power Unit (The Heart)

The power unit, containing a pump and motor, is responsible for generating the flow and pressure (PSI) of the hydraulic fluid. A pressure relief valve sets the maximum system pressure, acting as a built-in safety mechanism to prevent overload.

The Hydraulic Cylinder (The Muscle)

The cylinder, or "ram," is where the force multiplication happens. Its diameter dictates the surface area on which the fluid pressure acts. A larger ram diameter provides a greater surface area, resulting in higher tonnage for the same amount of system pressure.

The Frame (The Skeleton)

The frame is the structural backbone of the press. It must be designed to withstand the machine's maximum rated tonnage without flexing or failing. A press rated for 100 tons has a frame significantly more robust than one rated for 20 tons.

Understanding the Trade-offs: Tonnage vs. Speed

Choosing a press isn't just about finding the highest tonnage. There is a fundamental trade-off between the force a press can generate and the speed at which it can operate.

The Inverse Relationship

For a given hydraulic pump output (measured in gallons per minute), there is an inverse relationship between force and speed. A large-diameter ram requires more fluid to move a certain distance, so it will move more slowly but deliver higher force.

A smaller-diameter ram requires less fluid, allowing it to move faster but at the cost of lower maximum tonnage. High-speed production presses often use complex hydraulic circuits to achieve rapid approach speeds before slowing down for the high-force pressing segment.

Beyond Maximum Tonnage

It is critical to understand that a press should not be operated at its maximum rated tonnage continuously. A common rule of thumb is to select a press where your typical working load is around 80% of its rated capacity.

Consistently running a press at 100% of its rating puts significant strain on the frame, seals, and hydraulic components, leading to premature wear and potential failure.

How to Select the Right Press Rating

Choosing the correct rating depends entirely on your application's requirements for force, speed, and precision.

- If your primary focus is high-force forming or coining: You need high tonnage, so this rating should be your primary selection criterion.

- If your primary focus is high-speed assembly or punching: You need speed, so pay close attention to the ram's advance/retract speeds and consider a lower-tonnage press if the force is sufficient.

- If your primary focus is general-purpose workshop use: You need versatility, so find a balance and avoid choosing a press with excessive tonnage that you will never use, as it may be unnecessarily slow.

By understanding that tonnage is the true measure of a press's power, you can look beyond a single number and choose a machine that truly fits your operational needs.

Summary Table:

| Key Concept | Description | Why It Matters |

|---|---|---|

| Tonnage | Total output force (in tons) the press can exert. | The primary specification for comparing press capability and power. |

| System Pressure (PSI) | Pressure of the hydraulic fluid inside the system. | A component factor; high PSI alone does not guarantee high force. |

| Ram Area | Surface area of the main hydraulic cylinder. | Larger area multiplies system pressure to create higher tonnage. |

| Frame Strength | Structural capacity of the press frame. | Must withstand the full rated tonnage to ensure safety and precision. |

Need a hydraulic press that delivers the right force and speed for your specific tasks?

At KINTEK, we specialize in providing robust and reliable lab equipment, including hydraulic presses tailored to your unique application requirements. Whether you need high-tonnage for forming or high-speed for assembly, our experts will help you select the perfect press to enhance your lab's productivity and ensure long-lasting performance.

Contact our team today for a personalized consultation and discover the KINTEK difference!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Heat Press Machine

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How do you prepare XRF samples? Master the Two Key Methods for Accurate Results

- What are the advantages of press forging over hammer forging? Achieve Superior Internal Integrity

- What is the purpose of a laboratory hydraulic press in FTIR analysis? Create High-Quality Transparent Pellets

- What is the use of a hydraulic pellet press? Transform Powders into Precise Samples for Analysis

- What size micron is a filter press? It's All About the Filter Cloth You Choose

- What are the specific conditions and steps in HPHT diamond growth? Master the Art of Synthetic Diamond Production

- How do graphite granules formed by hydraulic press perform in stability testing? Achieve Unmatched Electrode Resilience

- What are the preventive maintenance of hydraulic press machine? Maximize Uptime and Prevent Costly Failures