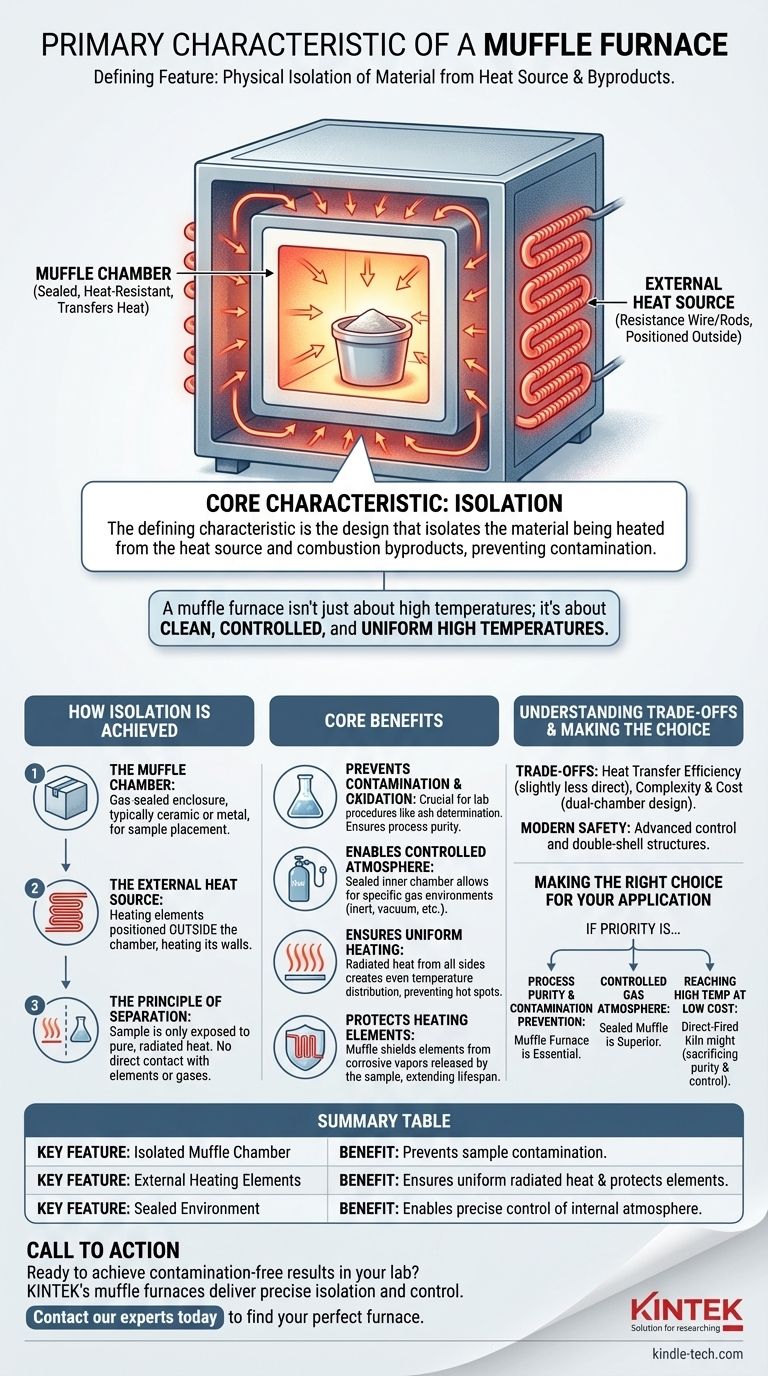

The defining characteristic of a muffle furnace is its design, which physically isolates the material being heated from the heat source and any byproducts of combustion. The sample is placed inside a separate, sealed chamber—the "muffle"—which is then heated from the outside. This fundamental separation prevents any contamination, ensuring the integrity of the process and the material.

A muffle furnace isn't just about achieving high temperatures; it's about achieving clean, controlled, and uniform high temperatures. Its core value lies in creating a pure heating environment by separating the workload from the heating elements and their byproducts.

How a Muffle Furnace Achieves Isolation

The genius of the muffle furnace lies in its simple but effective architecture. It is essentially a furnace within a furnace, designed to act as a barrier.

The Muffle Chamber

The "muffle" is the central component. It is a box-like, gas-sealed enclosure, typically made of a material that can withstand extreme temperatures and transfer heat efficiently. The material or sample to be treated is placed exclusively inside this chamber.

The External Heat Source

The heating elements, such as resistance wire, silicon carbon rods, or silicon-molybdenum rods, are positioned outside the muffle chamber. They heat the walls of the muffle, which in turn radiates that heat evenly into the isolated chamber.

The Principle of Separation

This design ensures that the sample never comes into direct contact with the heating elements or any gases produced during combustion. The only thing the sample is exposed to is pure, radiated heat within a contained environment.

The Core Benefits of This Design

This separation is not just an arbitrary design choice; it delivers critical advantages for scientific and industrial processes where precision is non-negotiable.

Prevents Contamination and Oxidation

This is the primary purpose. For laboratory procedures like ash determination, coal analysis, or materials science research, any external contaminants would invalidate the results. The muffle ensures the process is entirely pure.

Enables a Controlled Atmosphere

Because the inner chamber is sealed, operators can control the atmosphere within it. This allows for processes that require a specific gas environment (like nitrogen for inert heating) or even a vacuum, which is impossible in a direct-fired furnace.

Ensures Uniform Heating

The walls of the muffle heat up and radiate energy inward from all sides. This creates an extremely uniform temperature distribution throughout the chamber, preventing hot spots and ensuring the entire sample is treated evenly.

Protects Heating Elements

The muffle also works in reverse, protecting the furnace itself. It shields the expensive heating elements from any corrosive vapors or gases that might be released from the sample during heating, significantly extending the lifespan of the equipment.

Understanding the Trade-offs

While highly effective, the muffle design has inherent characteristics that you must consider when choosing the right equipment for your needs.

Heat Transfer Efficiency

Because heat must first be transferred through the walls of the muffle to reach the sample, the heating process can be slightly less direct than in a kiln where the sample is exposed directly to the heat source. However, modern designs are highly efficient.

Complexity and Cost

The dual-chamber construction makes a muffle furnace a more complex and often more expensive piece of equipment than a simple direct-fired kiln. The cost is justified by the level of control and purity it provides.

Modern Safety and Control

Newer muffle furnaces incorporate advanced features to manage their power. These often include double-shell structures for cooling and sophisticated temperature control systems, along with safety mechanisms for over-current, over-voltage, and leakage protection.

Making the Right Choice for Your Application

To determine if a muffle furnace is the correct tool, evaluate your primary goal.

- If your primary focus is process purity and preventing sample contamination: A muffle furnace is the essential choice, as its isolated chamber is specifically designed for this purpose.

- If you need to maintain a specific, controlled gas atmosphere around your sample: The sealed nature of the muffle makes it far superior to any direct-fired alternative.

- If your primary focus is simply reaching a high temperature at the lowest possible cost: A direct-fired kiln might be sufficient, but you will sacrifice the protection, uniformity, and control that a muffle furnace guarantees.

Ultimately, choosing a muffle furnace is a decision to prioritize precision and purity in your high-temperature work.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Isolated Muffle Chamber | Prevents sample contamination from heating elements and combustion byproducts. |

| External Heating Elements | Ensures uniform, radiated heat and protects elements from corrosive sample vapors. |

| Sealed Environment | Enables precise control of the internal atmosphere (e.g., inert gas, vacuum). |

Ready to achieve contamination-free results in your lab?

KINTEK's muffle furnaces are engineered with the precise isolation and control your sensitive applications demand. Whether you're performing ash determination, materials research, or any process requiring a pure thermal environment, our equipment delivers the reliability and precision you need.

Contact our experts today to find the perfect muffle furnace for your laboratory's unique requirements.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the objective of a muffle furnace? Achieve Pure, High-Temperature Processing

- Why is a high-temperature drying oven required for cellulose residues? Ensure Precise Mass Balance and Dry Weight.

- What is ash content determination? Methods, Applications, and Key Insights

- What is the function of muffle furnace in food industry? Ensure Accurate Ash Determination for Quality Control

- How does a high-temperature furnace contribute to the densification of LLZTO? Expert Sintering Guide

- How is a muffle furnace used for sample digestion? A Guide to Dry Ashing for Accurate Analysis

- How are precision ovens used for PDMS curing? Achieve Superior Cross-Linking for High-Performance Substrates

- How does a high-precision heat treatment furnace contribute to GBE? Enhance Supercritical Water Corrosion Resistance