At its core, a dental sintering furnace is a specialized high-temperature oven. Its primary function is to heat dental restorations, most commonly those made from zirconia, after they have been milled. This process, known as sintering, transforms the soft, chalk-like material into a dense, hard, and durable final product suitable for clinical use as a crown, bridge, or framework.

The sintering furnace is the critical final step in the digital zirconia workflow. It bridges the gap between a fragile, precisely milled shape and a permanent, high-strength dental restoration ready for the patient.

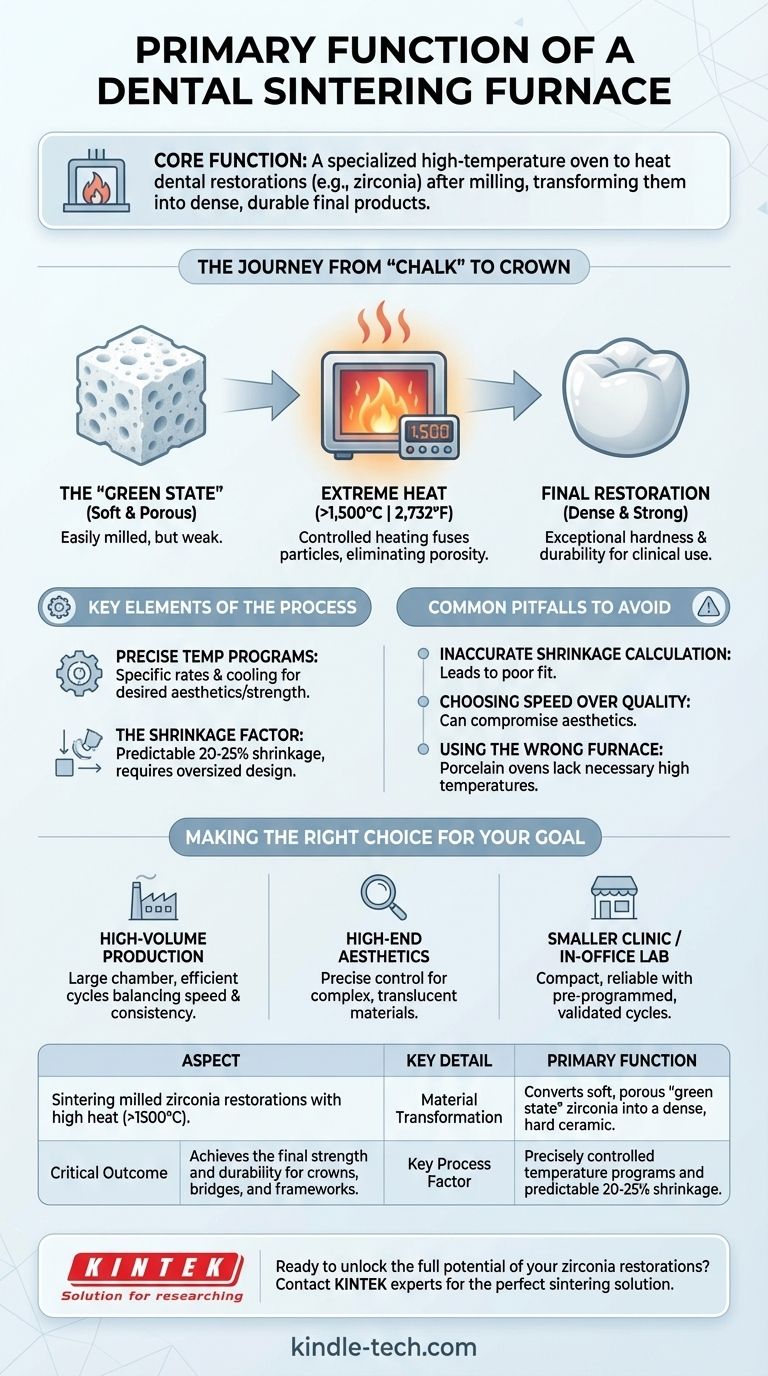

The Journey from "Chalk" to Crown

To understand the furnace's function, you must first understand the material it processes. Zirconia is a ceramic that is milled in a soft, pre-sintered state, often called the "green state."

The "Green State" of Zirconia

In this initial state, the zirconia is chalky and easy for a milling machine to shape with high precision. However, it is far too weak and porous to function as a dental restoration.

The Role of Extreme Heat

The sintering furnace applies controlled, extreme heat, often reaching temperatures above 1,500°C (2,732°F). This is significantly hotter than a standard dental porcelain oven.

The Sintering Transformation

At these high temperatures, the individual zirconia particles fuse together. The material becomes significantly denser, eliminating the porosity of the green state and gaining its exceptional final hardness and strength. Think of it like firing clay in a kiln to create a hard ceramic piece.

Key Elements of the Sintering Process

A reliable outcome depends on more than just high heat. The entire heating and cooling cycle is a precisely controlled process that dictates the final properties of the restoration.

Precise Temperature Programs

Different types of zirconia (e.g., high-strength vs. high-translucency) require specific heating rates, holding times, and cooling profiles. The furnace must execute these temperature programs with extreme accuracy to achieve the desired aesthetics and strength.

The Shrinkage Factor

During sintering, the zirconia restoration shrinks significantly as it densifies, typically by 20-25%. This shrinkage is not a flaw but a predictable part of the process. The initial design in the CAD software must be oversized by a precise factor to compensate for it, ensuring the final crown fits the patient perfectly.

Common Pitfalls to Avoid

While essential, the sintering process is not without its challenges. Understanding the potential trade-offs is crucial for any dental lab or clinic.

Inaccurate Shrinkage Calculation

The most common error is a miscalculation of the shrinkage factor. If the initial design is not scaled correctly, the final restoration will be too large or too small and will not fit, wasting time and materials.

Choosing Speed Over Quality

Some furnaces offer very fast sintering cycles, which is attractive for high-volume labs. However, rushing the heating and cooling process can sometimes compromise the final aesthetics, particularly the translucency, of certain advanced zirconia materials.

Using the Wrong Furnace

A sintering furnace is not interchangeable with a dental porcelain furnace. A porcelain furnace operates at much lower temperatures and is designed for layering ceramic powder, not for densifying a milled zirconia block. Using the wrong equipment will destroy the restoration.

Making the Right Choice for Your Goal

The right sintering furnace depends entirely on the goals and workflow of your dental practice or laboratory.

- If your primary focus is high-volume production: Look for a furnace with a large chamber capacity and proven, efficient sintering cycles that balance speed with consistent results.

- If your primary focus is high-end aesthetics: Prioritize a furnace known for its precise temperature control and ability to run complex, multi-stage programs required for highly translucent zirconia.

- If you are a smaller clinic or in-office lab: A compact, reliable furnace with pre-programmed, validated cycles for common materials offers the most straightforward and predictable workflow.

Ultimately, the sintering furnace is the essential tool that unlocks the full clinical potential of modern zirconia restorations.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Function | Sintering milled zirconia restorations with high heat (>1500°C). |

| Material Transformation | Converts soft, porous 'green state' zirconia into a dense, hard ceramic. |

| Critical Outcome | Achieves the final strength and durability for crowns, bridges, and frameworks. |

| Key Process Factor | Precisely controlled temperature programs and predictable 20-25% shrinkage. |

Ready to unlock the full potential of your zirconia restorations?

The right sintering furnace is critical for achieving consistent strength and aesthetics in your dental lab. KINTEK specializes in high-performance lab equipment, including dental sintering furnaces designed for accuracy and reliability.

Contact our experts today to find the perfect sintering solution for your workflow, whether you prioritize high-volume production or superior aesthetic results.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is an economical method for purging a porcelain furnace muffle? A Simple, High-Heat Cycle for Cleaner Dental Restorations

- What are the materials used in dental ceramics? Choosing the Right Material for Strength & Aesthetics

- What are the disadvantages of ceramic restoration? Weighing Aesthetics Against Durability and Cost

- Can a broken porcelain tooth be repaired? A Guide to Durable Dental Solutions

- What is a dental press used for? Creating High-Strength, Aesthetic Dental Restorations

- Are ceramic crowns stain-resistant? Discover the Secret to a Lasting, Bright Smile

- What is a dental burnout furnace? A Precision Tool for Flawless Dental Restorations

- What is a dental porcelain furnace? The Key to In-House, High-Quality Dental Restorations