At its core, the principle of Chemical Vapor Deposition (CVD) is a process that builds a solid, thin film on a surface from a gas phase. Precursor gases containing the required chemical elements are introduced into a reaction chamber where they are heated, causing them to react and decompose on a substrate, depositing the desired material layer by layer.

The essential principle of CVD is not merely coating a surface, but rather synthesizing a new solid material directly onto a substrate through controlled chemical reactions triggered by heat. It is a bottom-up construction process, building a film atom by atom from gaseous ingredients.

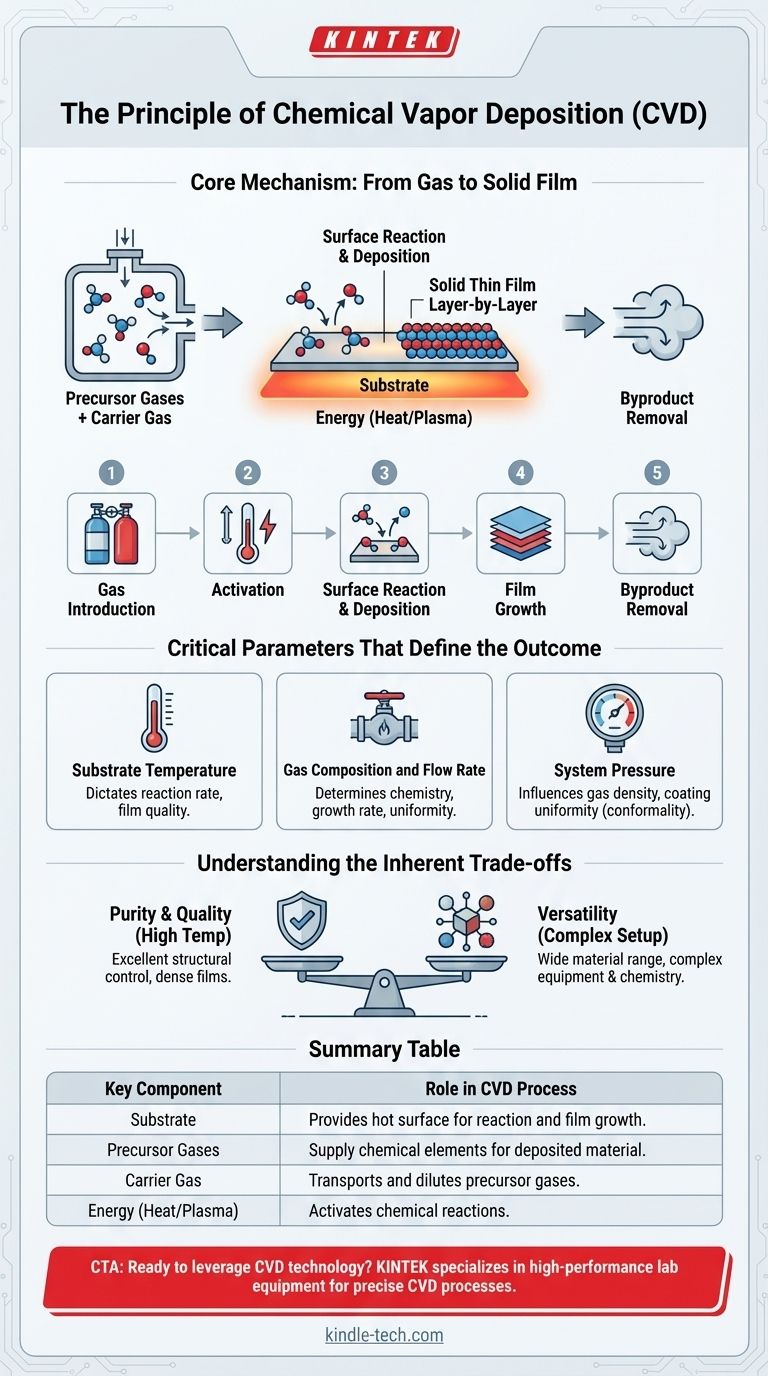

The Core Mechanism: From Gas to Solid Film

To truly understand CVD, you must visualize it as a controlled chemical construction project happening on a microscopic scale. The process relies on a few key components and a precise sequence of events.

The Essential Ingredients

- Substrate: This is the material or workpiece to be coated. Its primary role is to provide a hot surface that catalyzes and localizes the chemical reaction.

- Precursor Gases: These are volatile molecules that contain the atoms you want to deposit. For example, to deposit silicon, you might use silane gas (SiH4).

- Carrier Gas: An inert gas, like argon or nitrogen, is often used to dilute the precursor gases and transport them through the chamber at a controlled rate.

- Energy: Heat is the most common form of energy used. The substrate is typically heated to hundreds or even thousands of degrees Celsius to provide the energy needed to break chemical bonds. In some variants, plasma is used to energize the gases at lower temperatures.

The Step-by-Step Process

- Gas Introduction: A precise mixture of precursor and carrier gases is flowed into a sealed reaction chamber.

- Activation: The gases flow over the heated substrate. The high temperature provides the activation energy for the chemical reactions to begin.

- Surface Reaction & Deposition: The precursor gas molecules decompose or react with each other on or very near the hot substrate surface. The solid product of this reaction deposits onto the substrate, forming a film.

- Film Growth: This deposition continues, building the film layer by layer. The process is controlled to achieve a specific thickness and material structure.

- Byproduct Removal: Gaseous byproducts from the reaction (e.g., hydrogen gas from silane) are carried away by the gas flow and exhausted from the chamber.

Critical Parameters That Define the Outcome

The quality, composition, and structure of the deposited film are not accidental. They are the direct result of carefully controlling several key variables within the CVD process.

Substrate Temperature

This is arguably the most critical parameter. Temperature dictates the rate of the chemical reactions. Too low, and the reaction won't occur; too high, and you may get unwanted phases or poor film quality.

Gas Composition and Flow Rate

The chemistry of the final film is directly determined by the precursor gases you introduce. The flow rate affects the supply of reactants to the substrate surface, which in turn influences the growth rate and uniformity of the film.

System Pressure

The pressure inside the reaction chamber influences gas density and the path molecules take to the substrate. It plays a significant role in the film's purity and its ability to coat complex, non-flat surfaces uniformly (its "conformality").

Understanding the Inherent Trade-offs

Like any powerful technology, CVD involves fundamental trade-offs that are important to recognize. Understanding these helps clarify why it is chosen for certain applications and not others.

Purity and Quality vs. Conditions

CVD is renowned for its ability to produce exceptionally pure, dense, and well-adhered films with excellent structural control. This is why it's a cornerstone of the semiconductor industry.

The trade-off is that achieving this quality often requires very high temperatures. These temperatures can damage or fundamentally alter certain substrate materials, limiting the range of possible applications.

Versatility vs. Complexity

The process is incredibly versatile; by changing the precursor gases, you can deposit a vast range of materials, from insulators and semiconductors to hard metals and even synthetic diamond.

However, this requires complex equipment to handle high temperatures, vacuum conditions, and often toxic or corrosive precursor gases. The chemistry can be intricate and specific to each desired material.

How to Think About the CVD Principle

The best way to understand the principle is to see how it's applied to achieve different technical goals.

- If your primary focus is semiconductor fabrication: Think of CVD as the process used to build the critical insulating layers (like silicon dioxide) and conductive pathways (like polysilicon) on a silicon wafer with extreme precision.

- If your primary focus is wear resistance: View CVD as a method to create ultra-hard coatings, such as titanium nitride, on industrial cutting tools, dramatically extending their operational life.

- If your primary focus is advanced materials: See CVD as the fundamental technique for synthesizing materials that are difficult to produce otherwise, such as growing large, high-purity synthetic diamonds from methane gas.

Ultimately, chemical vapor deposition is a highly controlled method for chemically constructing a solid material directly onto a surface from the vapor phase.

Summary Table:

| Key Component | Role in CVD Process |

|---|---|

| Substrate | Provides a hot surface for reaction and film growth |

| Precursor Gases | Supply the chemical elements for the deposited material |

| Carrier Gas | Transports and dilutes precursor gases in the chamber |

| Energy (Heat/Plasma) | Activates the chemical reactions for decomposition and deposition |

Ready to leverage CVD technology in your lab? KINTEK specializes in high-performance lab equipment and consumables for precise chemical vapor deposition processes. Whether you're in semiconductor fabrication, materials science, or industrial coating, our solutions ensure superior film quality, adhesion, and process control. Contact our experts today to discuss how we can support your specific CVD application and enhance your research or production outcomes.

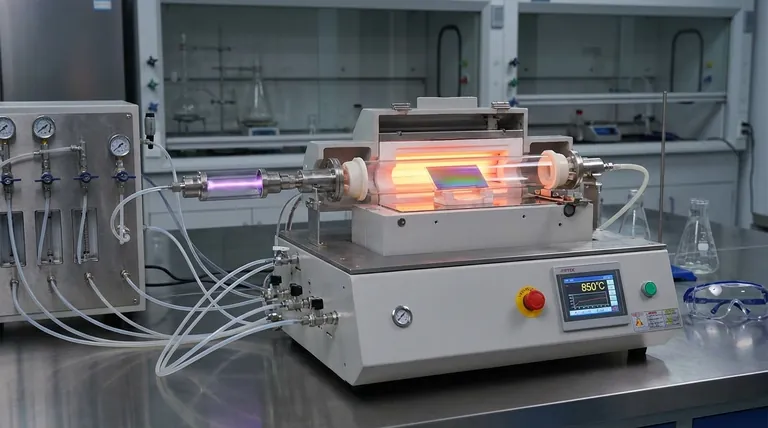

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the components of MOCVD? A Detailed Breakdown of This Advanced Deposition System

- What are the examples of CVD techniques? Compare APCVD, LPCVD, PECVD, and MOCVD

- What is the difference between sputtering and ion plating? Choose the Right PVD Coating for Your Application

- What are the applications of thin film deposition? From Electronics to Medical Devices

- What is the difference between CVD and MOCVD? Precision vs. Versatility in Thin-Film Deposition

- What is the chemical process deposition? A Guide to Chemical Vapor Deposition (CVD)

- What is vacuum in thin film? Master the Foundation for High-Quality Film Deposition

- What is chemical Vapour deposition of crystal growth? Build High-Quality Materials from the Atom Up