In principle, a single punch tablet press operates on a straightforward mechanical stamping cycle. It uses one set of tools—a die and a pair of upper and lower punches—to sequentially fill, compress, and eject a single tablet at a time. The lower punch creates a cavity in the die, which is filled with powder; the upper punch then descends with high force to compress the powder, and finally, the lower punch rises to eject the finished tablet.

The core concept is a sequential, single-station process. Unlike high-volume machines, the single punch press methodically produces one tablet per cycle, making it a precise instrument for development and small-scale applications rather than mass production.

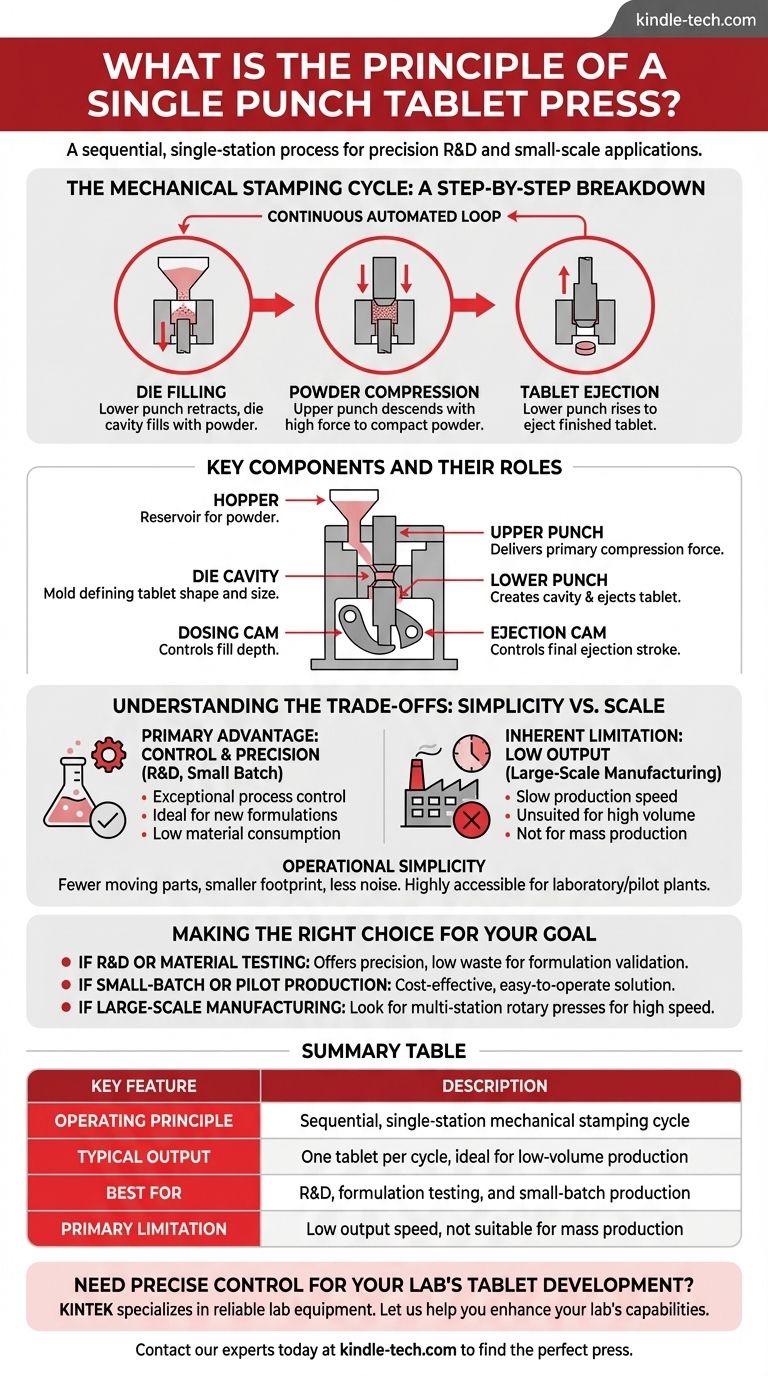

The Mechanical Cycle: A Step-by-Step Breakdown

The entire operation is a continuous, automated loop. Each step is precisely timed to ensure uniformity from one tablet to the next.

Step 1: Die Filling

The process begins when the lower punch retracts within the die cavity, creating a void. The dosing plow then moves over the die, pushing a measured amount of powder from the hopper into this cavity.

Step 2: Powder Compression

Once the die is filled, the dosing plow retracts, and any excess powder is scraped away to ensure a consistent volume. The upper punch then descends with a powerful, hammer-like motion, entering the die and exerting significant pressure on the powder.

This high force compacts the powder particles, binding them together to form a solid tablet.

Step 3: Tablet Ejection

After compression, the upper punch withdraws. The lower punch then rises within the die, pushing the newly formed tablet up and out of the cavity.

The finished tablet is then swept away, and the lower punch retracts to its starting position, ready for the cycle to begin again.

Key Components and Their Roles

Understanding the function of each core component clarifies the overall principle. These parts work in concert to ensure precision and consistency.

The Hopper

This is the reservoir that holds the bulk powder or granulated mixture before it is fed into the press for compression.

The Die Cavity

The die is the mold that dictates the final shape and diameter of the tablet. The powder is compressed inside this cavity.

The Upper and Lower Punches

These are the steel tools that directly apply force to the powder. The upper punch delivers the primary compression force, while the lower punch is responsible for both creating the initial cavity and ejecting the final tablet.

The Dosing and Ejection Cams

These mechanical components guide the movement of the punches. The dosing cam controls the fill depth by positioning the lower punch, while the ejection cam controls the final ejection stroke.

Understanding the Trade-offs: Simplicity vs. Scale

The single punch press is a specialized tool, and its operating principle creates clear advantages for certain applications and significant limitations for others.

The Primary Advantage: Control and Precision

Because it produces only one tablet at a time, this machine offers exceptional control over the process. It is ideal for research and development where new formulations are being tested.

Its low material consumption makes it perfect for working with minimal or expensive test materials.

The Inherent Limitation: Low Output

The sequential, single-station nature means production speed is inherently slow. This machine is fundamentally unsuited for large-scale or commercial manufacturing where thousands of tablets per minute are required.

Operational Simplicity

With fewer moving parts than a multi-station rotary press, the single punch machine is typically smaller, easier to operate, and generates less noise. This makes it highly accessible for laboratory or pilot plant settings.

Making the Right Choice for Your Goal

The single punch principle is not universally applicable. Your specific objective determines whether it is the correct tool for the job.

- If your primary focus is R&D or material testing: This machine offers the necessary precision and low material waste to validate new formulations effectively.

- If your primary focus is small-batch or pilot production: The single punch press provides a cost-effective and easy-to-operate solution before committing to expensive, high-volume equipment.

- If your primary focus is large-scale commercial manufacturing: You must look beyond this machine to a multi-station rotary press designed for high speed and volume.

Understanding this fundamental stamping principle empowers you to select the right tool for your specific production scale and development stage.

Summary Table:

| Key Feature | Description |

|---|---|

| Operating Principle | Sequential, single-station mechanical stamping cycle |

| Typical Output | One tablet per cycle, ideal for low-volume production |

| Best For | R&D, formulation testing, and small-batch production |

| Primary Limitation | Low output speed, not suitable for mass production |

Need precise control for your lab's tablet development?

A single punch tablet press is the ideal tool for research, formulation testing, and small-batch production, offering unmatched precision with minimal material waste. At KINTEK, we specialize in supplying reliable lab equipment, including tablet presses, to meet your specific research and development needs.

Let us help you enhance your lab's capabilities. Contact our experts today to find the perfect press for your projects!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

People Also Ask

- What are the advantages of press working operation? Unlock High-Speed, Low-Cost Mass Production

- What is the advantage of a single punch tablet machine? Ideal for Low-Waste R&D and Formulation Testing

- What is the pressed pellet technique? A Guide to Creating Uniform Solid Samples from Powder

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale