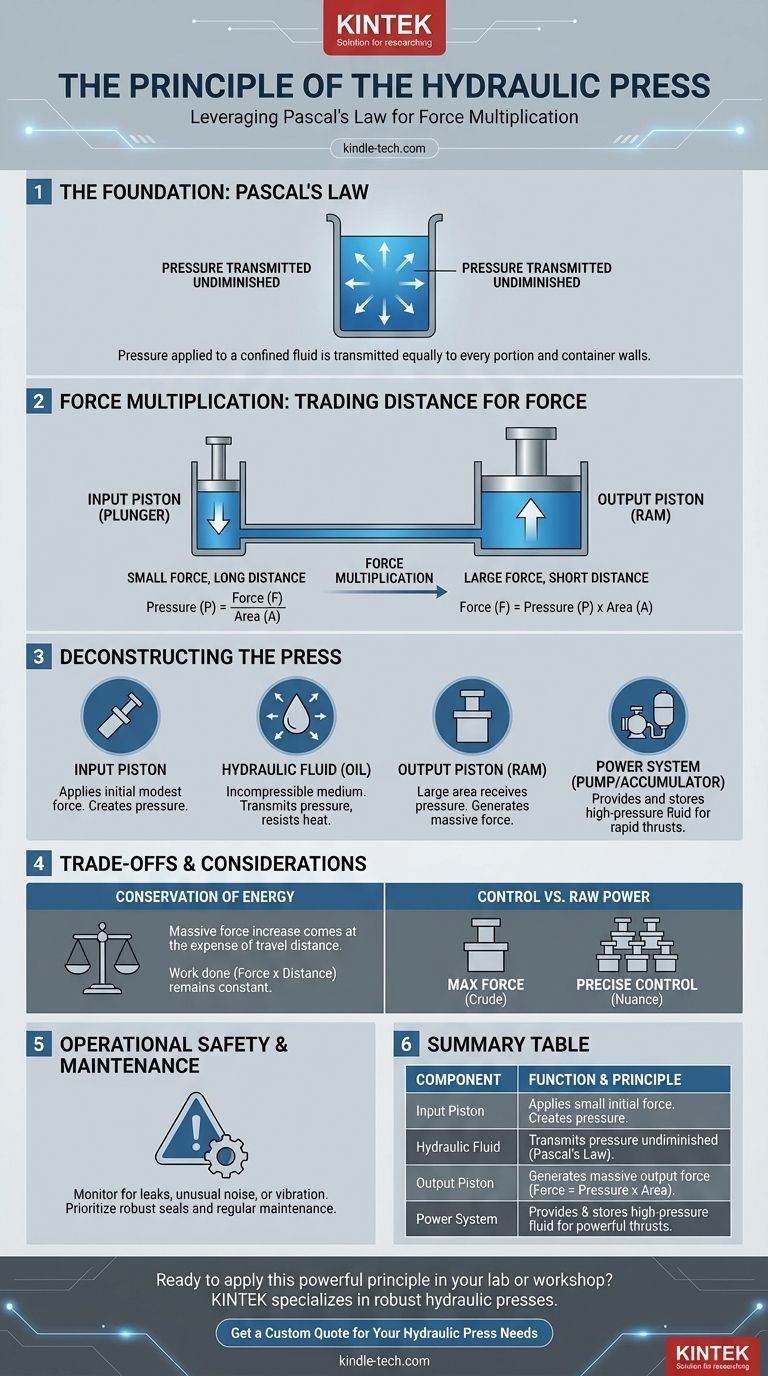

At its core, a hydraulic press operates on a fundamental principle of fluid mechanics known as Pascal's Law. This law states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel. In a press, a small force applied to a small piston creates pressure in a fluid (like oil), which then acts on a much larger piston, generating a proportionally larger output force.

A hydraulic press does not create energy; it masterfully trades distance for force. By applying a small force over a long distance on a small piston, it generates a massive force over a short distance on a large piston, all thanks to the uniform pressure within a confined fluid.

The Foundation: Understanding Pascal's Law

Pascal's Law is the simple yet powerful concept that makes hydraulic systems possible. It hinges on the relationship between force, pressure, and area.

Pressure in a Confined Fluid

When you apply force to a sealed fluid, the pressure increases everywhere within that fluid at once. The fluid's molecules transmit this pressure equally in all directions.

This is why a small input at one end of the system can have a significant effect at the other, regardless of the shape of the container connecting them.

The Force Multiplication Formula

The governing equation is Pressure = Force / Area. By rearranging this, we get Force = Pressure x Area.

Since Pascal's Law dictates that the pressure is constant throughout the fluid, the force exerted by the fluid is directly proportional to the surface area it acts upon. A piston with a larger area will experience a greater force than a piston with a smaller area.

An Intuitive Analogy

Imagine two sealed, water-filled syringes connected by a thin tube. One syringe is very narrow (the input), and the other is very wide (the output).

Pushing the small plunger with your thumb requires only a little effort. However, that same pressure is transmitted through the tube to the large plunger, generating a much greater output force—enough that you likely couldn't stop it with your other hand. This is force multiplication in action.

Deconstructing the Hydraulic Press

A hydraulic press is an elegant application of this principle, composed of a few key components working in concert.

The Input Piston (The Plunger)

This is the smaller piston where the initial, modest force is applied. A pump, often powered by an electric motor, pushes on this plunger, creating the initial pressure in the hydraulic fluid.

The Confined Fluid (The Medium)

This is almost always a specialized hydraulic oil. Oil is used because it is practically incompressible, resists heat, and lubricates the system's moving parts, ensuring smooth and efficient operation.

The Output Piston (The Ram)

This is the large-diameter piston that receives the transmitted pressure. Because its surface area is many times greater than the input plunger's, the force it exerts is also many times greater. This massive, controlled force is what presses, stamps, or forges the material.

The Power System

In industrial applications, a pump and hydraulic accumulator provide the high-pressure fluid. The accumulator acts like a rechargeable battery for pressure, storing the high-pressure liquid so it can be released on demand for powerful, rapid thrusts.

Understanding the Trade-offs and Pitfalls

While the principle is straightforward, its real-world application involves critical trade-offs and operational considerations.

The Conservation of Energy

You cannot get something for nothing. The massive increase in force comes at the expense of travel distance.

To move the large output ram by one inch, the small input plunger must travel a much greater distance. The work done (Force x Distance) remains the same on both sides of the system, ignoring minor efficiency losses.

Control vs. Raw Power

A single, massive ram can deliver immense compressive force. However, for more delicate forging or shaping operations, this can be too crude.

Some designs use multiple smaller rams instead of one large one. This allows operators to apply pressure more evenly or precisely, offering greater control over the final geometry of the workpiece.

Operational Safety and Maintenance

The high pressures involved make safety paramount. A system is only as strong as its weakest point.

Issues like serious oil leakage, unusual noise, or excessive vibration are critical warning signs that the machine must be stopped immediately. Seals can fail, and exceeding the machine's structural limits can lead to catastrophic failure.

Making the Right Choice for Your Goal

Understanding the core principle allows you to evaluate a hydraulic system based on its intended purpose.

- If your primary focus is maximum force multiplication: The key is the area ratio. A system with a much larger output ram relative to its input plunger will deliver the highest possible force.

- If your primary focus is precise control: Look for systems that utilize multiple, smaller rams or have advanced hydro-pneumatic controls, as these offer more nuance in applying pressure.

- If your primary focus is operational reliability: Prioritize systems with robust seals and a clear maintenance plan. Regularly monitor fluid levels and system integrity, as leaks are the first sign of a developing problem.

Ultimately, the hydraulic press is a testament to how a simple physical law, when engineered correctly, can be used to achieve extraordinary mechanical advantage.

Summary Table:

| Key Component | Function | Principle Applied |

|---|---|---|

| Input Piston (Plunger) | Applies small initial force | Creates pressure in the hydraulic fluid |

| Hydraulic Fluid (Oil) | Transmits pressure undiminished | Pascal's Law: Pressure is transmitted equally |

| Output Piston (Ram) | Generates massive output force | Force = Pressure x Area (Force Multiplication) |

| Power System (Pump/Accumulator) | Provides and stores high-pressure fluid | Enables powerful, rapid thrusts on demand |

Ready to apply this powerful principle in your lab or workshop?

At KINTEK, we specialize in providing robust and reliable hydraulic presses and other essential lab equipment. Whether you need maximum force for material testing or precise control for delicate shaping operations, our solutions are engineered for performance and safety.

Contact us today to discuss how our hydraulic presses can enhance your productivity and achieve your specific industrial or research goals. Let's build something powerful together.

Get a Custom Quote for Your Hydraulic Press Needs

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is the primary function of an industrial vertical hydraulic press? Mastering Steel-Vanadium Composite Fabrication

- How powerful is hydraulic pressure? Generate Immense Force for Heavy-Duty Applications

- What is the sample size for XRF? Achieve Accurate Analysis with Proper Sample Prep

- What is the primary function of a high-tonnage uniaxial hydraulic press? Optimize High-Entropy Alloy Consolidation

- Is forging a shaping process? Discover How It Enhances Material Strength and Durability

- How are moulding presses rated? A Guide to Clamping Force, Platen Size, and Key Specs

- What are the list of preventive maintenance tasks for a hydraulic system? A Proactive Guide to Maximize Uptime

- How do I choose an XRF analyzer? A Guide to Matching Analyzer Type to Your Application