The maximum pressure of a hydraulic press is not a single number, but a specification determined by its design and components. While a small benchtop press might operate at 2,000-3,000 PSI, standard industrial presses commonly run at 3,000 to 10,000 PSI. Highly specialized systems used for isostatic pressing or in laboratories can exceed 50,000 PSI.

A press's maximum pressure (PSI) is fundamentally limited by the strength of its weakest component—be it the cylinder, seals, or pump. However, focusing only on PSI is a mistake. The truly important metric is the output force (tonnage), which is the result of that internal pressure acting over the area of the cylinder.

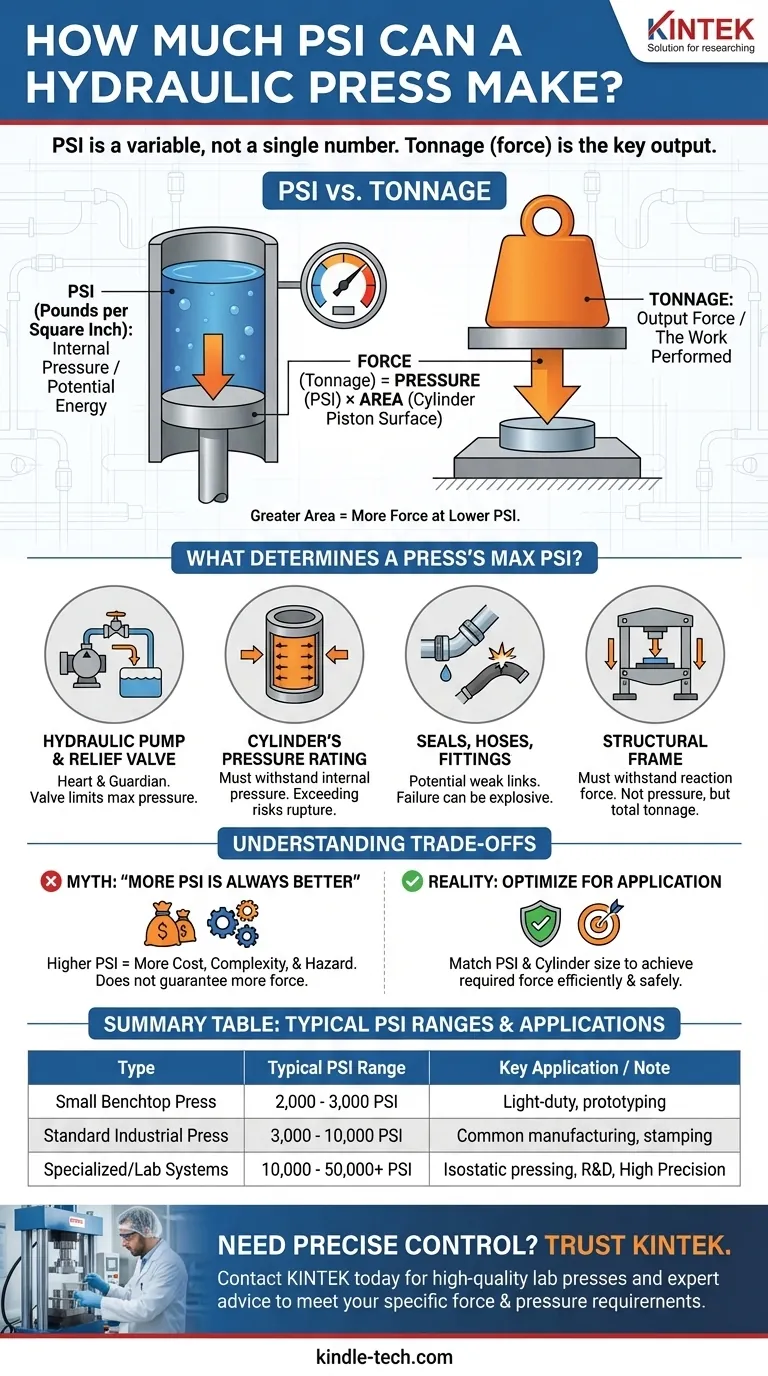

PSI vs. Tonnage: The Two Numbers That Matter

To understand the capability of a press, you must distinguish between the pressure inside the system and the force it delivers.

What is PSI (Pounds per Square Inch)?

PSI is the measure of pressure exerted by the hydraulic fluid on every square inch of the system's interior. Think of it as the potential energy or the "charge" within the system.

This pressure is generated by the hydraulic pump as it forces fluid into the cylinder.

What is Tonnage?

Tonnage is the measure of output force the press exerts on the workpiece. This is the "work" the press actually performs, whether it's stamping metal, compressing material, or molding a part. One ton of force is equal to 2,000 pounds of force.

The Formula That Connects Them

The relationship between internal pressure and output force is governed by a simple principle: Force = Pressure × Area.

This means the tonnage of a press is the result of the system's PSI multiplied by the surface area of the piston inside the main cylinder. This is why a press with a lower PSI but a much larger cylinder can produce more force than a press with a higher PSI and a smaller cylinder.

What Determines a Press's Maximum PSI?

The "nameplate" PSI is not an arbitrary number. It is a carefully engineered limit based on the capabilities of four critical components.

The Hydraulic Pump & Relief Valve

The pump is the heart of the system, creating the flow of fluid. However, the pressure relief valve acts as the system's guardian. This valve is set to a specific PSI and will divert fluid back to the tank if pressure exceeds that limit, preventing catastrophic failure. This setting is often the primary determinant of the machine's maximum operating pressure.

The Cylinder's Pressure Rating

The hydraulic cylinder must contain the immense forces generated by the pressurized fluid. Its walls, end caps, and piston are manufactured to a specific pressure rating. Attempting to operate a system beyond the cylinder's rating is the most direct path to a mechanical rupture.

Seals, Hoses, and Fittings

Every point where components connect is a potential weak link. Hydraulic seals, hoses, and fittings all have their own pressure ratings. In many systems, especially older ones, a failed seal or a burst hose is the first sign that the pressure limit has been exceeded.

The Structural Frame

The frame of the press does not hold pressure, but it must withstand the equal and opposite reaction force generated by the tonnage. A frame designed for a 50-ton output will fail if you install a cylinder and pump combination capable of producing 100 tons of force, regardless of the system's PSI.

Understanding the Trade-offs

Pursuing higher pressure without understanding the context leads to inefficiency and danger.

The Myth of "More PSI is Always Better"

Higher pressure is not inherently better. A system running at 10,000 PSI with a small 2-inch diameter piston generates significantly less force (~15 tons) than a system running at a modest 3,000 PSI with a large 10-inch diameter piston (~117 tons). The goal is to achieve the required force, not just a high PSI reading.

Safety: The High-Pressure Hazard

Hydraulic fluid under high pressure stores a massive amount of energy. A component failure does not result in a simple leak; it can result in an explosive release of fluid with enough force to cause severe injury or damage equipment.

Cost and Complexity

As operating pressures increase, the demands on materials and manufacturing tolerances rise exponentially. A 10,000 PSI system requires stronger, heavier, and more expensive cylinders, pumps, and fittings than a 3,000 PSI system.

How to Think About Pressure for Your Application

Use the concept of pressure to make informed decisions based on your specific goal.

- If your primary focus is selecting a pre-built press: Pay attention to the advertised tonnage and physical dimensions (work area). The manufacturer has already engineered the correct PSI and component combination to safely achieve that tonnage.

- If your primary focus is designing a hydraulic system: Start by calculating the force (tonnage) you need. Then, select a cylinder that fits your size constraints, and only then calculate the PSI required to achieve your target force.

- If your primary focus is operating a press: Understand that the pressure gauge reflects the system's effort. If the press is rated for 50 tons and you are only doing a 10-ton job, the gauge will show a much lower PSI than its maximum rating.

Ultimately, understanding pressure is the key to safely and effectively harnessing the immense power of hydraulics.

Summary Table:

| Hydraulic Press Type | Typical PSI Range | Key Application / Note |

|---|---|---|

| Small Benchtop Press | 2,000 - 3,000 PSI | Light-duty tasks, prototyping |

| Standard Industrial Press | 3,000 - 10,000 PSI | Common manufacturing, stamping |

| Specialized/Lab Systems | 10,000 - 50,000+ PSI | Isostatic pressing, R&D |

Need precise pressure control for your lab work?

Understanding the relationship between PSI and tonnage is critical for achieving accurate and repeatable results in material testing, sample preparation, and more. KINTEK specializes in high-quality lab equipment, including hydraulic presses and consumables designed for reliability and safety.

Let our experts help you select the perfect press to meet your specific force and pressure requirements. Contact KINTEK today to discuss your laboratory's needs!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the purpose of using laboratory hydraulic presses for molecular sieve catalysts? Optimize Reactor Performance

- What will you do to reduce prevent excessive heating of oil in a hydraulic system? A Guide to Boosting Efficiency & Reliability

- What are the industrial applications of plate and frame filter press? A Guide to Efficient Solid-Liquid Separation

- What is the application of a laboratory hydraulic press in catalyst preparation? Optimize Your Cellulose Conversion

- What affects the quality of pellets? A Guide to Achieving Durable, High-Density Biomass Pellets

- Can a hydraulic press crush steel? Harness Immense Force for Industrial Shaping and Testing

- What is the principle of forging press? Achieve Superior Strength with Controlled Metal Deformation

- What is the role of a hydraulic pellet press in preparing vanadium-titanium magnetite? Optimize Densification & Reactivity