At its core, vacuum hardening is a high-precision heat treatment process used to increase the hardness and strength of steel components. It involves heating the material to a critical temperature within a controlled, oxygen-free vacuum environment and then rapidly cooling it. The vacuum’s primary purpose is to protect the component’s surface, preventing reactions like oxidation and decarburization that occur in traditional atmospheric furnaces.

The crucial insight is that vacuum hardening isn't just about making metal harder; it's about achieving that hardness with exceptional precision and surface integrity. By eliminating atmospheric gases, the process prevents surface defects and distortion, making it the superior choice for high-performance components where a pristine, ready-to-use finish is critical.

The Principle: Why Use a Vacuum?

The use of a vacuum is the defining feature of this process, offering significant advantages over conventional heat treatments that take place in atmospheric conditions.

Eliminating Surface Reactions

In a traditional furnace, the oxygen present in the air reacts with the hot steel surface. This creates an undesirable layer of oxide scale and can deplete carbon from the surface layer (decarburization), weakening the final component.

A vacuum furnace removes virtually all the air, creating an inert environment that prevents these harmful reactions.

Ensuring Uniform Heating

The controlled environment of a vacuum furnace allows for extremely precise and uniform temperature control. This eliminates hot spots and ensures that the entire component, including complex geometries, heats and cools at a consistent rate, minimizing internal stresses and distortion.

Achieving a Bright, Clean Finish

Because no oxidation occurs, parts emerge from a vacuum furnace with a bright, clean, and metallic surface. This often eliminates the need for costly and time-consuming secondary operations like sandblasting, grinding, or machining to remove scale.

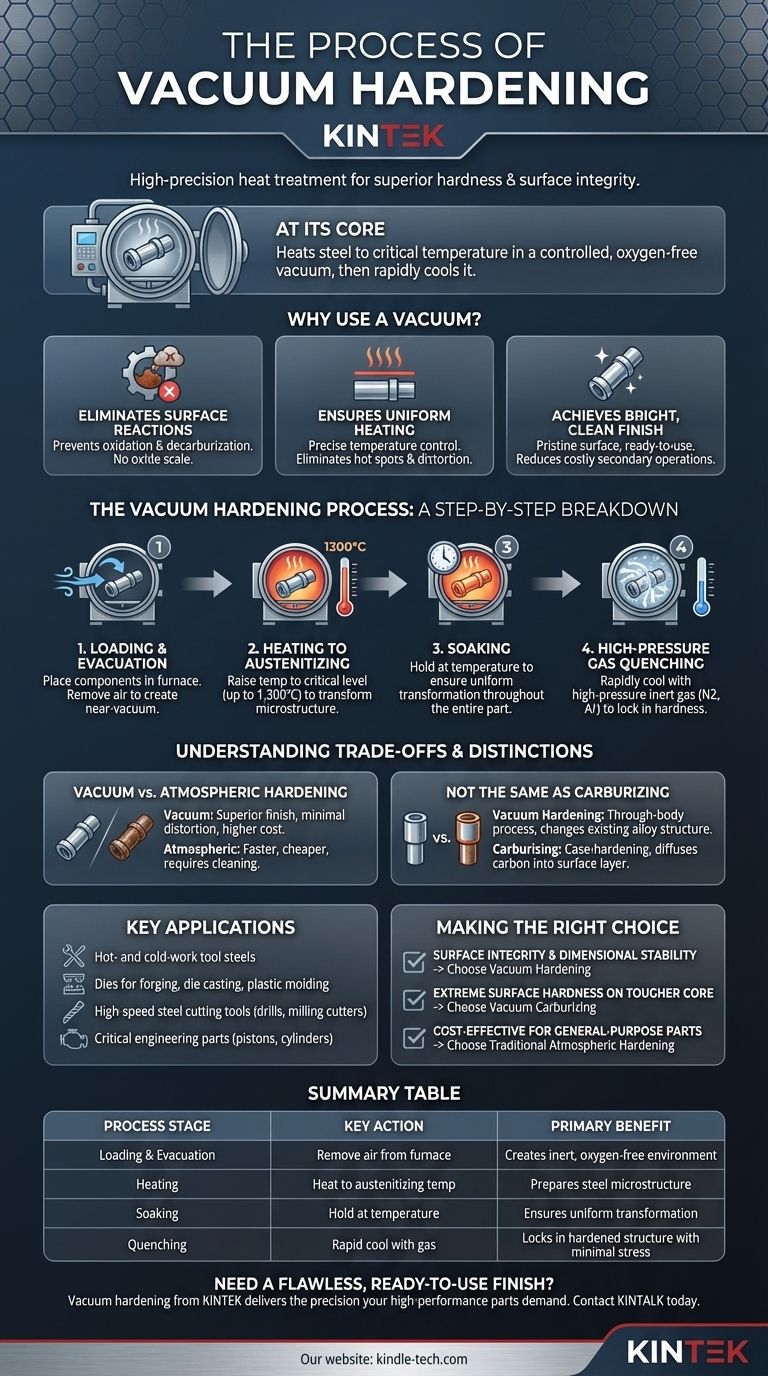

The Vacuum Hardening Process: A Step-by-Step Breakdown

While specific parameters vary based on the steel alloy, the fundamental process follows four distinct stages.

Step 1: Loading and Evacuation

Components are carefully placed into the sealed vacuum furnace chamber. A powerful pumping system then removes the air and other gases, creating a near-vacuum environment at a specific partial pressure.

Step 2: Heating to Austenitizing Temperature

The furnace temperature is precisely raised to the material's specific austenitizing temperature, which can be up to 1,300°C. This is the critical temperature at which the steel's crystal structure transforms, preparing it for hardening. Modern computer controls ensure high accuracy and repeatability during this phase.

Step 3: Soaking

The component is held at the austenitizing temperature for a predetermined period. This "soaking" phase ensures the structural transformation is complete and uniform throughout the entire mass of the part.

Step 4: High-Pressure Gas Quenching

Once soaking is complete, the hardening is achieved by rapid cooling, known as quenching. In a vacuum furnace, this is typically done by flooding the chamber with a high-pressure, inert gas like nitrogen or argon. The gas circulates rapidly, extracting heat quickly and controllably to achieve the desired hardness.

Understanding the Trade-offs and Distinctions

While highly effective, vacuum hardening is not a universal solution. Understanding its context is key to its proper application.

Vacuum Hardening vs. Atmospheric Hardening

The primary trade-off is between surface quality and cost. Atmospheric hardening is often faster and less expensive but requires post-treatment cleaning. Vacuum hardening delivers a superior finish and minimal distortion directly from the furnace, justifying its use for high-value parts.

Crucial Distinction: Not the Same as Carburizing

Vacuum hardening should not be confused with vacuum carburizing. Hardening is a through-body process that changes the structure of the existing alloy. Carburizing is a case-hardening process where a carbon-rich gas (like propane) is introduced to diffuse carbon into the surface of the part, creating a hard outer layer over a softer core.

Key Applications

The benefits of this process make it ideal for components where precision and material integrity are paramount. Common applications include:

- Hot- and cold-work tool steels

- Dies for forging, die casting, and plastic molding

- High-speed steel cutting tools like drills and milling cutters

- Critical engineering parts such as pistons, cylinders, and industrial knives

Making the Right Choice for Your Goal

Selecting the correct heat treatment method depends entirely on the component's final requirements for performance, finish, and cost.

- If your primary focus is surface integrity and dimensional stability: Vacuum hardening is the ideal choice for parts that cannot tolerate oxidation, decarburization, or distortion.

- If your primary focus is extreme surface hardness on a tougher core: You should investigate a case-hardening process like vacuum carburizing.

- If your primary focus is cost-effective hardening for general-purpose parts: Traditional atmospheric hardening may be sufficient, provided you account for the necessary post-process cleaning and finishing.

Ultimately, selecting vacuum hardening is a decision to prioritize precision, material purity, and a flawless final product directly from the furnace.

Summary Table:

| Process Stage | Key Action | Primary Benefit |

|---|---|---|

| Loading & Evacuation | Remove air from the furnace chamber | Creates an inert, oxygen-free environment |

| Heating | Heat to austenitizing temperature (up to 1300°C) | Prepares steel microstructure for transformation |

| Soaking | Hold at temperature for a set time | Ensures uniform transformation throughout the part |

| Quenching | Rapidly cool with high-pressure inert gas (N2, Ar) | Locks in the hardened structure with minimal stress |

Need a flawless, ready-to-use finish on your critical components?

Vacuum hardening from KINTEK delivers the precision and surface integrity your high-performance parts demand. Our expertise in lab and industrial heat treatment equipment ensures your tool steels, dies, and cutting tools achieve superior hardness without oxidation, decarburization, or distortion.

Contact KINTALK today to discuss how our vacuum hardening solutions can enhance your product quality and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What precautions should be taken during annealing? Ensure Material Integrity and Performance

- What is the method of sintering? A Guide to Building Strong, Dense Components from Powder

- What is the relationship between temperature and pressure in a vacuum? Mastering Thermal Control for Optimal Vacuum Performance

- What are the components of a vacuum furnace? Master the Core Systems for Superior Heat Treatment

- What is the purpose of treating FeCrAl alloys in a high-temperature annealing furnace after hot rolling?

- Why is a high-vacuum stainless steel reaction chamber necessary for NTP? Ensure High-Purity Plasma Treatment

- Why is nitrogen used in sintering? Balancing Cost, Oxidation Control, and Material Properties

- What is the function of a high-temperature solution furnace in PWHT? Restore Alloy 800H Joint Integrity