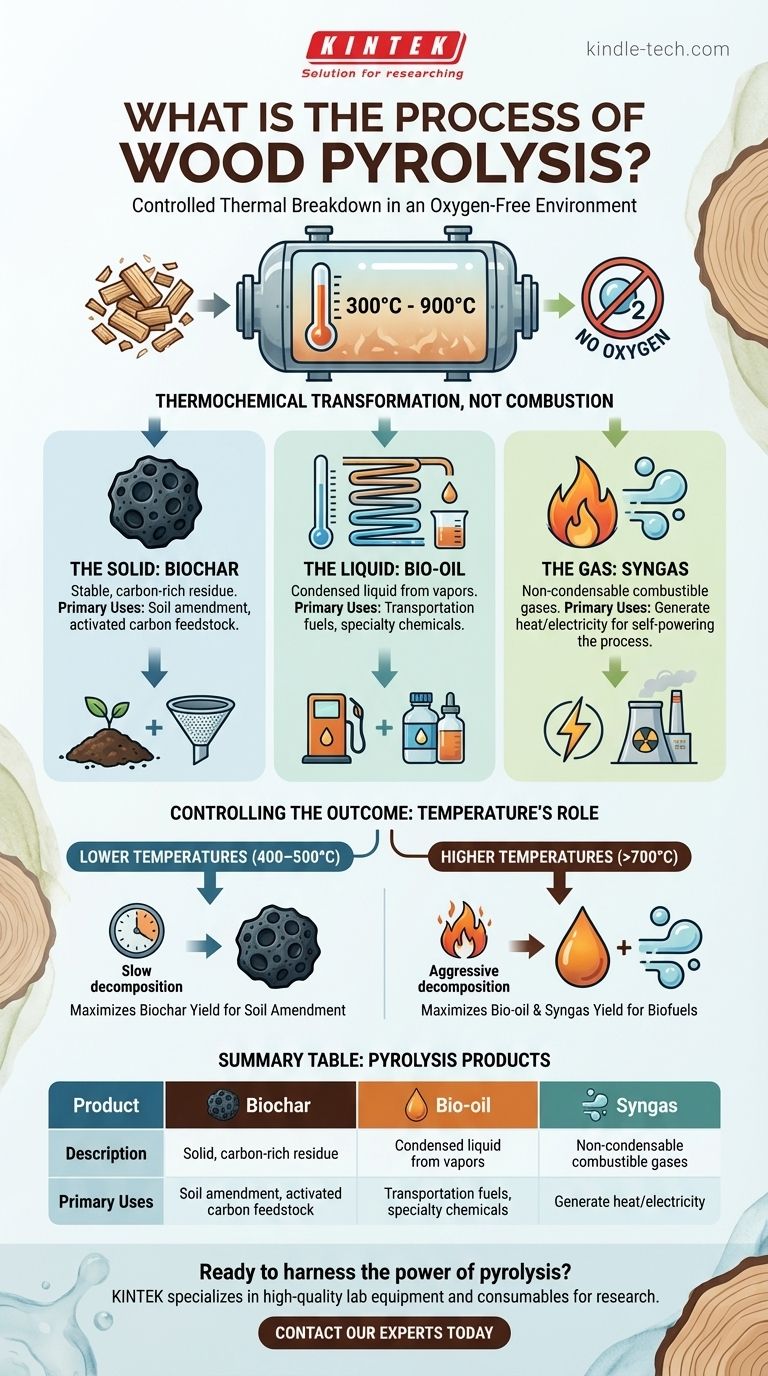

At its core, wood pyrolysis is the process of chemically decomposing wood using high heat in an environment without oxygen. This is not burning; it is a controlled thermal breakdown that transforms the solid biomass into a range of completely new and valuable products. The process typically occurs in a sealed reactor at temperatures between 300°C and 900°C.

The critical takeaway is that pyrolysis is a transformation, not a destruction. By carefully controlling heat and eliminating oxygen, you can precisely dictate whether the original wood becomes a stable solid (biochar), a liquid fuel (bio-oil), or a combustible gas (syngas).

The Core Mechanism: Heat Without Oxygen

Pyrolysis is a thermochemical process, a term derived from the Greek words 'pyro' (fire) and 'lysis' (separation). It is literally the act of separating a substance using heat.

Why the Absence of Oxygen is Critical

When wood is heated in the presence of oxygen, it burns—a process called combustion. This reaction releases energy as heat and light, leaving behind a small amount of ash.

In pyrolysis, the absence of oxygen prevents combustion from occurring. Instead of burning, the high heat breaks the complex chemical bonds within the wood's primary components—cellulose, hemicellulose, and lignin—causing them to decompose into simpler, more stable substances.

What Happens Inside the Reactor

The process begins by feeding wood into a sealed chamber called a reactor. This reactor is heated to a target temperature, driving off any residual moisture first.

As the temperature climbs, the wood begins to decompose, releasing a mixture of gases and vapors. These are then channeled out of the reactor and cooled, which separates them into the final liquid and gas products, leaving the solid charcoal behind.

The Three Primary Products of Pyrolysis

The transformation of wood results in three distinct outputs, each with its own set of uses. The proportion of each product depends heavily on the process conditions.

The Solid: Biochar

The solid residue left in the reactor is biochar, a stable, carbon-rich material similar to charcoal.

It is highly porous and can be used as a powerful soil amendment to improve water retention or as a feedstock for producing activated carbon for filtration.

The Liquid: Bio-oil

As the hot vapors from the reactor are cooled, they condense into a dark, thick liquid known as pyrolysis oil or bio-oil.

This complex mixture of organic compounds can be upgraded into transportation fuels or used as a source for specialty chemicals.

The Gas: Syngas

The gases that do not condense into liquid form are collectively known as synthesis gas or syngas.

This mixture of combustible gases, including hydrogen and carbon monoxide, can be burned to generate heat or electricity, often to power the pyrolysis plant itself in a self-sustaining cycle.

Understanding the Trade-offs: Controlling the Outcome

Pyrolysis is not a one-size-fits-all process. The final yield of biochar, bio-oil, and syngas is a direct result of the specific conditions used, creating a critical set of trade-offs for the operator.

The Decisive Role of Temperature

Temperature is the single most important variable for controlling the output of a pyrolysis reaction.

Lower temperatures, typically in the 400–500°C range, break down the wood more slowly and favor the production of the solid residue, maximizing the yield of biochar.

Higher temperatures, often above 700°C, cause more aggressive and complete decomposition of the wood into vapors. This dramatically increases the yield of liquid (bio-oil) and gaseous (syngas) fuels.

Making the Right Choice for Your Goal

The optimal pyrolysis strategy depends entirely on the desired end product. By adjusting the process parameters, you can steer the outcome to meet a specific objective.

- If your primary focus is creating a stable soil amendment: Operate at lower temperatures (400–500 °C) to maximize the production of high-quality biochar.

- If your primary focus is producing biofuels: Utilize higher temperatures (above 700 °C) to break the wood down into its liquid and gas components, maximizing the yield of bio-oil and syngas.

- If your primary focus is efficient waste conversion: Design the system to capture and burn the syngas produced, creating a self-sufficient process that powers its own heating requirements.

Ultimately, wood pyrolysis is a powerful and flexible platform for converting renewable biomass into a customized slate of valuable products simply by mastering the application of heat.

Summary Table:

| Product | Description | Primary Uses |

|---|---|---|

| Biochar | Solid, carbon-rich residue | Soil amendment, activated carbon feedstock |

| Bio-oil | Condensed liquid from vapors | Transportation fuels, specialty chemicals |

| Syngas | Non-condensable combustible gases | Generate heat/electricity for self-powering the process |

Ready to harness the power of pyrolysis for your biomass conversion projects? KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and development. Whether you are optimizing biochar production for agriculture or developing bio-oil refining processes, our reactors and analytical tools provide the precision and reliability you need. Contact our experts today to discuss how we can support your laboratory's specific pyrolysis goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the different types of pyrolysis machines? Choose the Right System for Your Output