The fundamental purpose of a muffle is to create an isolated chamber within a furnace. This chamber separates the material being heated from the direct flames, combustion gases, and other byproducts of the heat source, ensuring a clean and controlled heating process.

A muffle acts as a protective shield inside a furnace. It transforms a raw, potentially contaminating heat source into a clean, uniform thermal environment, which is critical for processes where sample purity and temperature consistency are paramount.

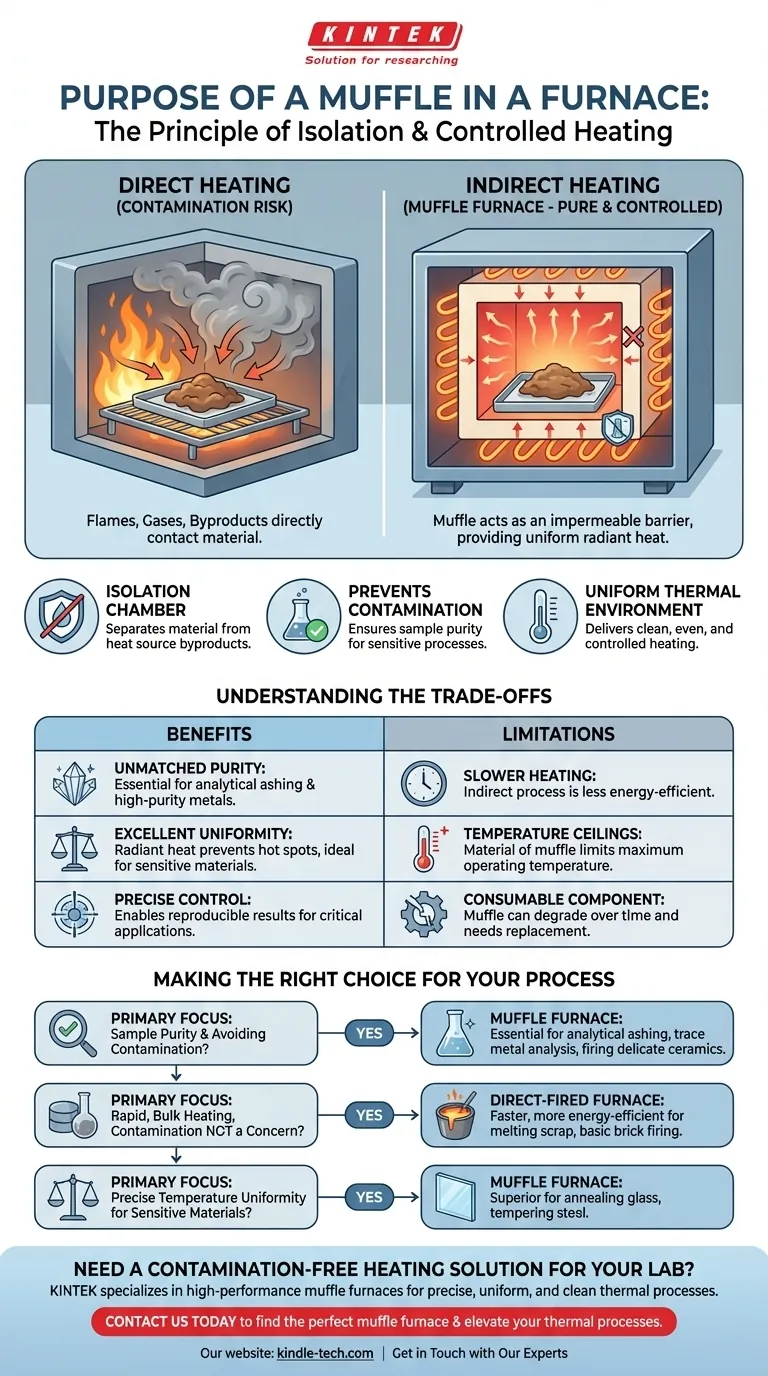

How a Muffle Works: The Principle of Isolation

A muffle furnace is not simply a box that gets hot; its design is centered on the principle of indirect heating. Understanding this is key to grasping its value.

The Muffle as a Protective Chamber

A muffle is essentially a box-like enclosure, typically made of a high-temperature ceramic, placed inside a larger furnace. The furnace's heating elements or gas burners heat the outside of the muffle.

The material or sample you wish to heat is placed inside the muffle. It never comes into direct contact with the flame or heating coils.

Indirect vs. Direct Heating

In a direct-fired furnace, the flame and hot gases circulate around the material itself. While efficient, this process introduces contaminants like soot, ash, and unburnt fuel directly onto the sample's surface.

A muffle furnace uses indirect heating. The muffle chamber absorbs the heat and then radiates it uniformly onto the sample. This creates a much more controlled environment, similar to how a convection oven cooks with hot air rather than a direct flame.

Preventing Chemical Contamination

The most critical function of a muffle is preventing contamination. In many scientific and industrial applications, the chemical purity of the final product is essential.

Byproducts from a gas flame can react with the material being heated, altering its chemical composition and rendering it useless for its intended purpose. The muffle acts as an impermeable barrier against these reactive gases.

Understanding the Trade-offs

While essential for certain tasks, using a muffle introduces specific performance trade-offs compared to direct heating methods.

Benefit: Unmatched Purity and Control

The primary advantage is a completely clean heating environment. This is non-negotiable for applications like ashing biological samples for chemical analysis, creating dental prosthetics, or treating high-purity metals. The radiant heat also provides excellent temperature uniformity.

Limitation: Slower Heating and Lower Efficiency

Because the heat must first transfer to the muffle and then radiate to the sample, the process is inherently slower and less energy-efficient than direct heating. The muffle itself represents a significant thermal mass that must be brought to temperature.

Limitation: Material and Temperature Ceilings

The muffle itself is a consumable component that can degrade over time, especially at extreme temperatures. The material of the muffle (e.g., alumina, silicon carbide) dictates the maximum operating temperature of the furnace.

Making the Right Choice for Your Process

Deciding whether you need a muffle furnace comes down to the requirements of your specific application.

- If your primary focus is sample purity and avoiding contamination: A muffle furnace is the only choice for processes like analytical ashing, trace metal analysis, or firing delicate ceramics.

- If your primary focus is rapid, bulk heating where contamination is not a concern: A simpler, direct-fired furnace or kiln will be faster and more energy-efficient for tasks like melting scrap metal or firing basic bricks.

- If your primary focus is precise temperature uniformity for sensitive materials: The even, radiant heat from a muffle is superior for processes like annealing glass or tempering steel, where hot spots could ruin the part.

Ultimately, a muffle transforms a raw heat source into a precise, clean, and controlled thermal tool.

Summary Table:

| Aspect | Muffle Furnace (Indirect Heating) | Direct-Fired Furnace |

|---|---|---|

| Sample Purity | Excellent (prevents contamination) | Poor (exposed to flames/gases) |

| Heating Speed | Slower (due to indirect heating) | Faster (direct contact with heat) |

| Temperature Uniformity | High (radiant, even heat) | Can have hot spots |

| Ideal For | Analytical ashing, dental ceramics, high-purity metals | Bulk melting, basic brick firing |

Need a contamination-free heating solution for your lab?

At KINTEK, we specialize in high-performance muffle furnaces designed to protect your samples and ensure precise, uniform results for applications like analytical ashing, heat treatment, and ceramic firing. Our lab equipment provides the clean, controlled thermal environment your sensitive work demands.

Contact us today to find the perfect muffle furnace for your laboratory's specific needs and elevate the quality of your thermal processes.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a sintering furnace? A Guide to High-Temperature Materials Processing

- What is the difference between ashing and wet digestion? Choosing the Right Sample Prep Method

- What is the working principle of a muffle furnace? Achieve Precise, Contamination-Free Heating

- How are furnaces used for LLTO nanowire preparation? Optimize Thermal Calcination for Better Battery Electrolytes

- What key role does a laboratory preheating oven play in the formation process of cellulose-lignin composite coatings?

- How is a high-temperature box muffle furnace used in the synthesis of Al2(SiO4)O? Master Ceramic Phase Engineering

- What is a furnace for ash determination? Unlock Accurate Mineral Content Analysis

- What role does a laboratory muffle furnace play in biosynthesized ZrO2? Achieve High-Purity Nanoparticle Calcination