In Chemical Vapor Deposition (CVD), argon's primary roles are to act as an inert carrier and diluent gas. It creates a stable, non-reactive environment, transports the reactant chemicals to the substrate, and controls their concentration to ensure a high-quality, uniform film deposition.

Argon is not a passive background element in CVD; it is a critical process control tool. By managing the chemical environment and the concentration of reactants, it directly dictates the rate of deposition, the purity of the film, and the safety of the entire operation.

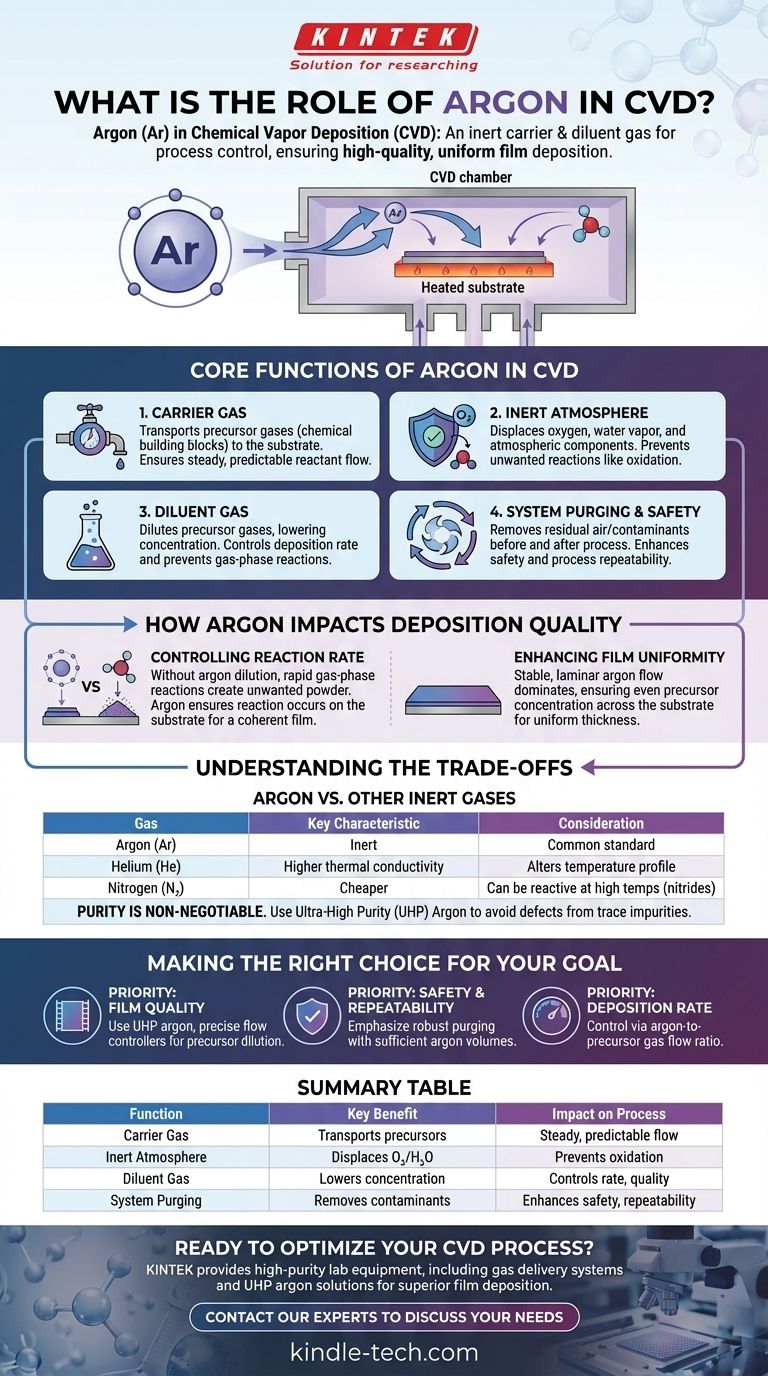

The Core Functions of Argon in CVD

Chemical Vapor Deposition relies on precise control over a gas-phase chemical reaction that results in a solid film. Argon, being chemically inert, provides the stable environment and transport mechanism required for this precision.

Acting as a Carrier Gas

The fundamental job of argon is to transport the precursor gases—the chemical building blocks of the final film—to the substrate surface. It acts as the delivery vehicle, ensuring a steady and predictable flow of reactants into the reaction chamber.

Creating an Inert Atmosphere

CVD precursor gases are often highly reactive and sensitive to air. Argon displaces oxygen, water vapor, and other atmospheric components from the chamber. This prevents unwanted side reactions, such as oxidation, which would create impurities and compromise the structural and electronic properties of the deposited film.

Serving as a Diluent Gas

Argon is used to dilute the precursor gases, lowering their partial pressure and overall concentration. This is not simply about saving costs; it is a critical method for controlling the deposition process. By adjusting the argon-to-precursor ratio, engineers can finely tune the film's growth rate.

System Purging and Safety

Before a deposition begins, argon is used to purge the chamber and gas lines, removing any residual air or contaminants. After the process, it purges the remaining toxic or flammable precursor gases, making the system safe to handle and preparing it for the next run.

How Argon Impacts Deposition Quality

The flow rate and purity of the argon gas have a direct and measurable impact on the final product. Understanding these effects is key to optimizing any CVD process.

Controlling the Reaction Rate

Without a diluent gas, precursor concentrations would be too high, potentially leading to rapid, uncontrolled reactions in the gas phase. This creates unwanted powder instead of a coherent film on the substrate. By diluting the precursors, argon ensures the reaction primarily occurs on the heated substrate surface, leading to a dense, high-quality film.

Enhancing Film Uniformity

A stable, laminar flow of gas is essential for ensuring that all parts of the substrate are exposed to the same concentration of precursor molecules. Since argon typically makes up the vast majority of the gas in the chamber, its flow characteristics dominate, helping to achieve a film of uniform thickness across the entire substrate.

Understanding the Trade-offs

While argon is the most common choice, it is not the only one, and its selection involves considering specific process requirements. The key is understanding that the "inert" gas is an active component of the system.

Argon vs. Other Inert Gases

Gases like helium (He) and nitrogen (N₂) are also used. Helium has a much higher thermal conductivity than argon, which can alter the temperature profile in the chamber. Nitrogen is cheaper than argon but can be reactive at high temperatures, forming nitrides in certain materials, making it unsuitable for processes where this is a contaminant.

Purity is Non-Negotiable

The effectiveness of argon hinges entirely on its purity. Even trace amounts of oxygen or water in the argon supply can be enough to introduce defects into the film. Using ultra-high purity (UHP) gas and maintaining leak-free gas lines is essential for achieving high-quality results.

Making the Right Choice for Your Goal

Your process goals will determine how you utilize and manage your argon supply.

- If your primary focus is film quality: Prioritize using the highest purity argon available and implement precise mass flow controllers to finely regulate the dilution of your precursor gases.

- If your primary focus is process safety and repeatability: Emphasize robust purging cycles, using sufficient volumes of argon before and after each run to ensure a clean, inert, and safe chamber environment.

- If your primary focus is controlling deposition rate: Your main control variable will be the argon-to-precursor gas flow ratio, as this directly determines the concentration of reactants reaching the substrate.

Ultimately, viewing argon as a foundational tool for process control is the key to mastering Chemical Vapor Deposition.

Summary Table:

| Function | Key Benefit | Impact on Process |

|---|---|---|

| Carrier Gas | Transports precursor gases | Ensures steady, predictable reactant flow |

| Inert Atmosphere | Displaces oxygen/water vapor | Prevents oxidation and unwanted reactions |

| Diluent Gas | Lowers precursor concentration | Controls deposition rate and film quality |

| System Purging | Removes contaminants and toxic gases | Enhances safety and process repeatability |

Ready to optimize your CVD process with precision gas control?

At KINTEK, we specialize in providing the high-purity lab equipment and consumables—including gas delivery systems and ultra-high purity (UHP) argon solutions—that are essential for achieving superior film deposition results. Whether your goal is ultimate film quality, enhanced safety, or precise deposition rate control, our expertise can help you master your CVD operations.

Contact our experts today to discuss your specific laboratory needs and discover how KINTEK can support your success.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition