The construction of a muffle furnace relies on a layered system of specialized materials, each chosen for a specific role in managing extreme heat. The core inner chamber, or muffle, is made from high-temperature ceramics capable of withstanding temperatures up to 1800°C. This is surrounded by insulating refractory materials like ceramic fiber and bricks, and the entire unit is enclosed in a durable stainless steel casing for structural integrity and user safety.

The key takeaway is not that one material is best, but that a muffle furnace is a system of materials working in concert. The design strategically layers materials to withstand extreme heat internally, insulate effectively in the middle, and provide a safe, durable exterior.

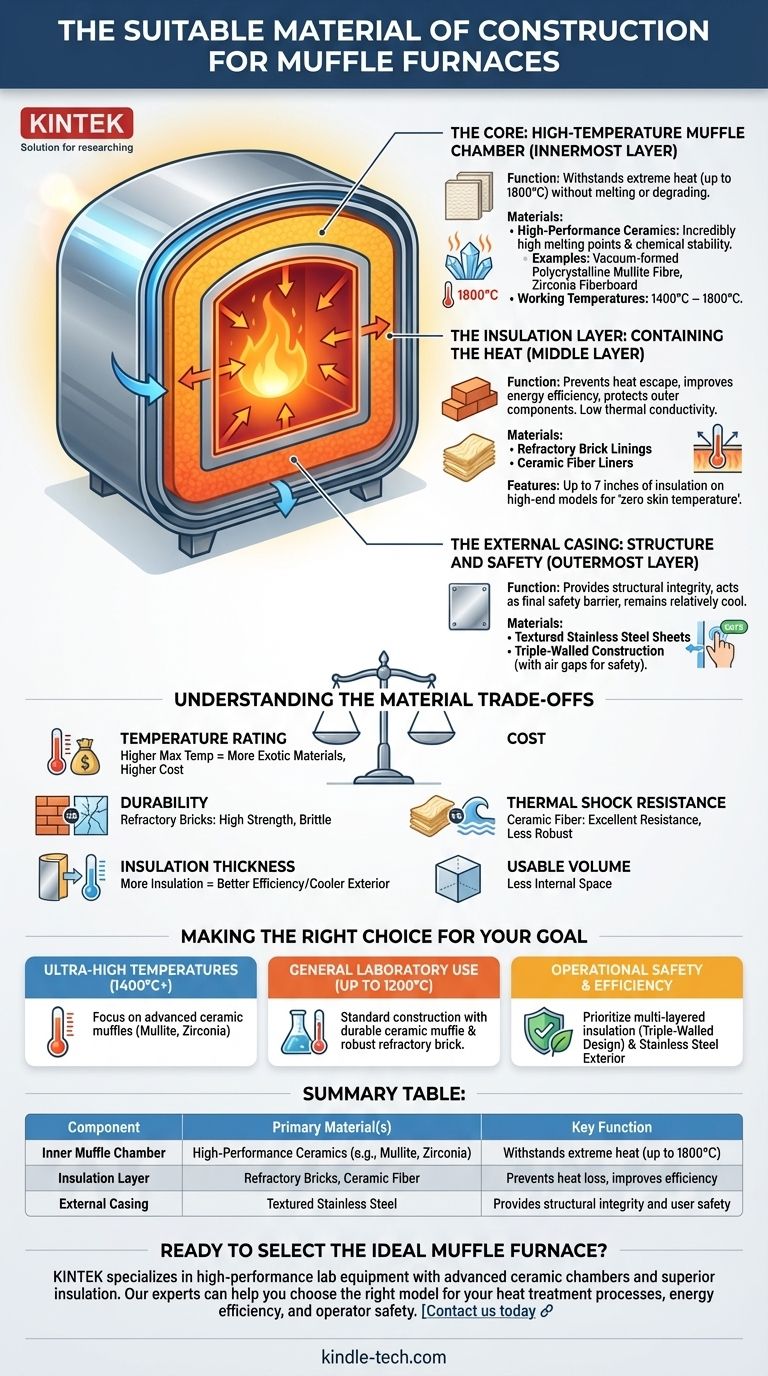

The Anatomy of a Muffle Furnace: A Material for Every Function

A muffle furnace's construction is a masterclass in thermal management. Each component's material is selected to perform a critical function, from generating and containing heat to ensuring the operator's safety.

The Core: The High-Temperature Muffle Chamber

This is the innermost chamber, where the work happens. The material here must endure the highest temperatures without melting or degrading.

The primary choice is high-performance ceramics. These materials are defined by their incredibly high melting points and chemical stability.

Specific examples include vacuum-formed polycrystalline mullite fibre and zirconia fiberboard. These advanced ceramics allow furnaces to reach working temperatures between 1400°C and 1800°C.

The Insulation Layer: Containing the Heat

Surrounding the muffle chamber is a thick layer of insulation. Its sole purpose is to prevent heat from escaping, which improves energy efficiency and protects the outer components.

Materials used include refractory brick linings and ceramic fiber liners. These materials have very low thermal conductivity.

High-end laboratory models may feature up to 7 inches of insulation on all sides, creating a "zero skin temperature" on the outer surface for maximum safety and efficiency.

The External Casing: Structure and Safety

The outermost layer provides the furnace's structure and acts as the final safety barrier.

This housing is almost always made of textured stainless steel sheets.

Stainless steel is chosen for its durability, resistance to corrosion, and ability to remain relatively cool. In many designs, a triple-walled construction with air gaps further aids in keeping the exterior safe to touch.

Understanding the Material Trade-offs

The specific materials used in a muffle furnace represent a balance of performance, cost, and durability. Understanding these trade-offs is key to interpreting a furnace's specifications.

Temperature Rating vs. Cost

Higher maximum temperatures demand more exotic and expensive materials. A furnace rated for 1200°C can use standard ceramic and refractory brick.

A furnace designed to operate at 1800°C, however, requires premium materials like high-purity zirconia or mullite, significantly increasing its cost.

Durability vs. Thermal Shock Resistance

Refractory bricks are extremely durable and have great compressive strength, but they can be brittle and susceptible to cracking if heated or cooled too quickly (thermal shock).

Ceramic fiber insulation, by contrast, has excellent resistance to thermal shock but may be less mechanically robust and can degrade over time with repeated use or physical contact.

Insulation Thickness vs. Usable Volume

Thicker insulation provides superior energy efficiency and a cooler external surface.

However, for a given external footprint, increasing the insulation thickness directly reduces the internal chamber volume available for processing your materials.

Making the Right Choice for Your Goal

When evaluating a muffle furnace, look at the material specifications to understand its true capabilities.

- If your primary focus is reaching ultra-high temperatures (1400°C+): Look for furnaces specifying advanced ceramic muffles made from materials like high-purity mullite or zirconia fiberboard.

- If your primary focus is general laboratory use (up to 1200°C): A standard construction with a durable ceramic muffle and robust refractory brick insulation is often the most cost-effective choice.

- If your primary focus is operational safety and energy efficiency: Prioritize models that emphasize multi-layered insulation (e.g., "triple-walled design") and a stainless steel exterior to ensure a cool-to-the-touch surface.

Understanding this layered material system empowers you to look beyond the maximum temperature and select a furnace truly suited to your application's demands.

Summary Table:

| Muffle Furnace Component | Primary Material(s) | Key Function |

|---|---|---|

| Inner Muffle Chamber | High-Performance Ceramics (e.g., Mullite, Zirconia) | Withstands extreme heat (up to 1800°C) |

| Insulation Layer | Refractory Bricks, Ceramic Fiber | Prevents heat loss, improves efficiency |

| External Casing | Textured Stainless Steel | Provides structural integrity and user safety |

Ready to select the ideal muffle furnace for your lab's specific temperature and safety requirements? KINTEK specializes in high-performance lab equipment, including muffle furnaces with advanced ceramic chambers and superior insulation. Our experts can help you choose the right model to enhance your heat treatment processes, improve energy efficiency, and ensure operator safety. Contact us today to discuss your application needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the temperature of furnace exhaust? A Key Indicator of Efficiency and Safety

- What is a muffle furnace used for in microbiology? Essential for Depyrogenation and Ashing

- How do you check the ash content of a muffle furnace? A Step-by-Step Guide to Material Analysis

- What is a muffle furnace used for ash determination? Achieve Precise Inorganic Analysis

- What is ashing in a muffle furnace? Isolate Inorganic Content with Precision