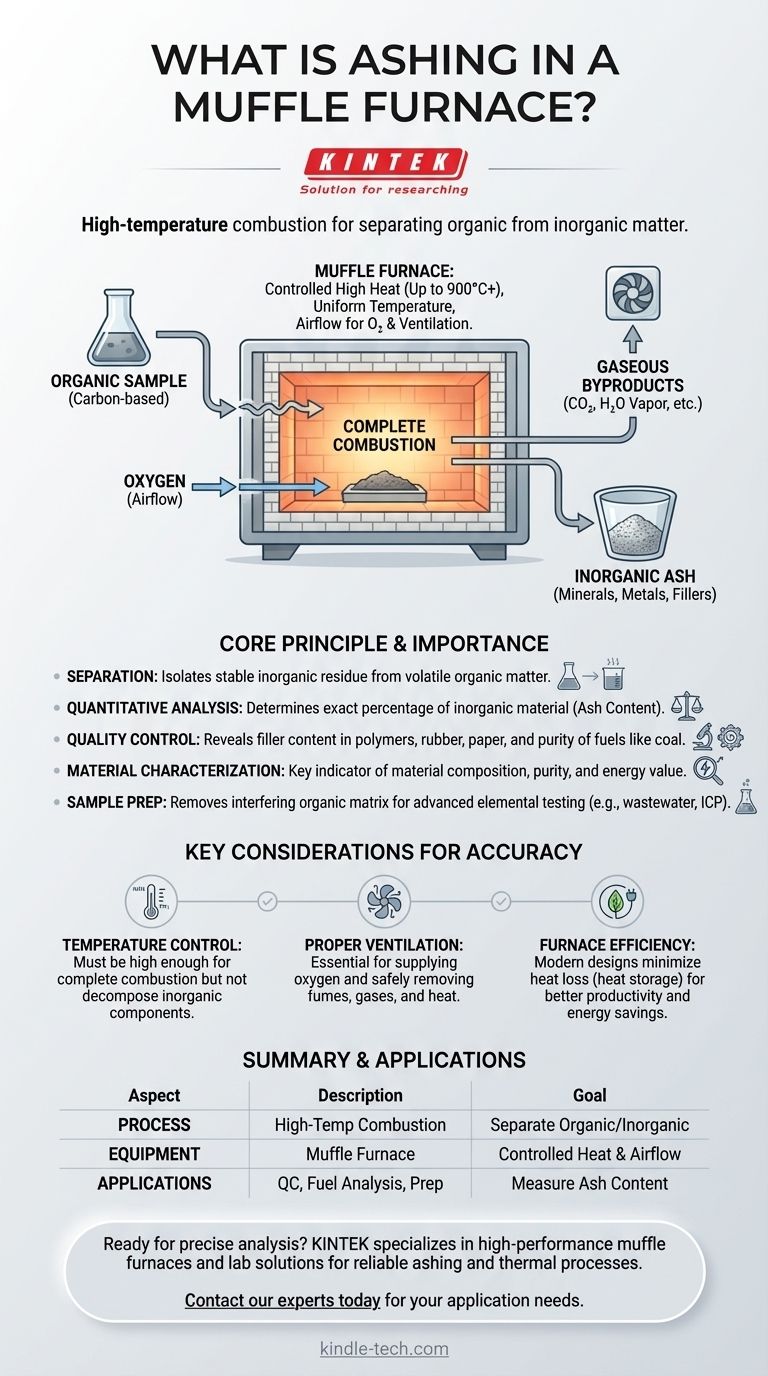

In material analysis, ashing is a high-temperature combustion process used to completely burn away the organic components of a sample. This is performed inside a specialized oven called a muffle furnace, which provides a controlled environment with sufficient air. The purpose is to isolate the remaining inorganic, non-combustible residue—the "ash"—for quantitative analysis.

The core purpose of ashing is not simply to burn a sample, but to precisely separate its volatile organic matter from its stable inorganic matter. This allows you to accurately measure the inorganic content, which is critical for quality control, material characterization, and further chemical analysis.

The Core Principle of Ashing

Separating Organic from Inorganic

The fundamental goal of ashing is to use high heat and oxygen to induce complete combustion.

During this process, the carbon-based organic compounds in the sample react with oxygen in the air and are converted into gaseous byproducts, such as carbon dioxide and water vapor, which are then vented.

The inorganic materials, such as minerals, metals, and fillers, do not combust. They remain behind as a solid ash residue.

The Role of the Muffle Furnace

A muffle furnace, often called an ashing furnace, is an essential tool for this process. It is designed to reach and maintain very high, uniform temperatures, often up to 900°C or more.

The furnace's internal chamber is typically lined with heat-absorbing brick masonry, which ensures a stable temperature environment for consistent results.

Crucially, these furnaces are designed to allow for controlled airflow, which provides the necessary oxygen for combustion and helps to vent the fumes and excess heat produced.

Why the Ash is Important

By carefully weighing the sample before and after the ashing process, an analyst can determine the exact percentage of inorganic material it contains.

This "ash content" is a critical data point in many fields. It can reveal the amount of mineral filler in a plastic, the purity of coal, or the presence of specific contaminants.

Common Applications and Industries

Quality Control in Manufacturing

Ashing is a routine quality control test for materials like polymers, rubber, and paper.

It is used to verify the "filler content"—the percentage of inorganic additives like calcium carbonate or silica that are mixed into a product to modify its properties or reduce cost.

Material and Energy Analysis

In the analysis of materials like coal and other fuels, the ash content is a primary indicator of quality. A lower ash content typically means a higher energy value.

The technique is also applied to agricultural products, such as grain, to determine their mineral content.

Environmental and Sample Preparation

Ashing serves as a critical preparation step for more advanced analytical techniques. For example, it can remove an interfering organic matrix before elemental analysis.

Specific applications include determining volatile suspended solids in wastewater effluent and cleaning laboratory equipment like ICP torches by burning off organic residues.

Understanding the Trade-offs and Key Considerations

Temperature Control is Paramount

The selected temperature must be high enough to ensure complete combustion of all organic material. If the temperature is too low, the process will be incomplete, leaving behind charred residue and yielding inaccurate results.

However, the temperature must not be so high that it causes the inorganic components themselves to decompose or vaporize, which would also lead to incorrect measurements.

The Necessity of Proper Ventilation

Adequate airflow serves two purposes. First, it continuously supplies the oxygen required for the combustion reaction.

Second, it ensures that fumes, gases, and excess heat are safely and effectively removed from the furnace chamber, protecting both the equipment and the operator.

Furnace Efficiency and Heat Loss

The brick lining of a muffle furnace absorbs a significant amount of heat during operation. This "heat storage loss" represents energy that is lost when the furnace cools down.

Modern furnaces are designed to minimize this energy loss, which improves heating times, increases productivity, and lowers overall power consumption.

Making the Right Choice for Your Goal

- If your primary focus is quality control (e.g., filler content): Ashing provides a direct and reliable measurement of the inorganic additives in materials like polymers or paper.

- If your primary focus is material characterization (e.g., coal analysis): The percentage of resulting ash is a critical indicator of material purity and energy value.

- If your primary focus is sample preparation for further analysis: Ashing is a powerful first step to remove interfering organic material that could compromise subsequent elemental testing.

Ultimately, ashing in a muffle furnace is a fundamental technique for revealing the true inorganic composition of a sample.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Goal | Separate and measure inorganic (ash) content from organic material. |

| Key Equipment | Muffle furnace (ashing furnace) for controlled high-temperature combustion. |

| Typical Applications | Quality control (polymers, rubber), fuel analysis (coal), sample prep for elemental analysis. |

| Critical Factors | Precise temperature control and adequate oxygen supply/ventilation. |

Ready to achieve precise material analysis in your lab?

KINTEK specializes in high-performance muffle furnaces and lab equipment designed for reliable ashing and other thermal processes. Our solutions help ensure accurate results for your quality control, material characterization, and sample preparation needs.

Contact our experts today to find the perfect furnace for your application and enhance your laboratory's capabilities.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do you check the ash content of a muffle furnace? A Step-by-Step Guide to Material Analysis

- What is the purpose of a muffle? To Ensure Pure, Contamination-Free Heating in Your Lab

- What are 2 advantages of dry ashing? Achieve High-Throughput Sample Analysis with Safety

- What are the advantages of a muffle furnace? Achieve Unmatched Purity and Precision in Your Lab

- What is commonly used during a dry ashing experiment? Essential Equipment for Accurate Ash Analysis