The temperature of a muffle furnace is not a single value, but rather a specified operating range that varies significantly between models. While general-purpose lab furnaces often operate up to 1100-1200°C (2192°F), specialized high-temperature versions can safely reach 1800°C (3272°F) or even higher for advanced material research. The correct temperature capability depends entirely on the furnace's design and its intended application.

The most critical point to understand is that a muffle furnace's temperature is defined by its application. You don't choose a furnace based on a generic temperature, but by selecting a model with a maximum temperature and control system that matches the specific requirements of your process, be it ashing, annealing, or sintering.

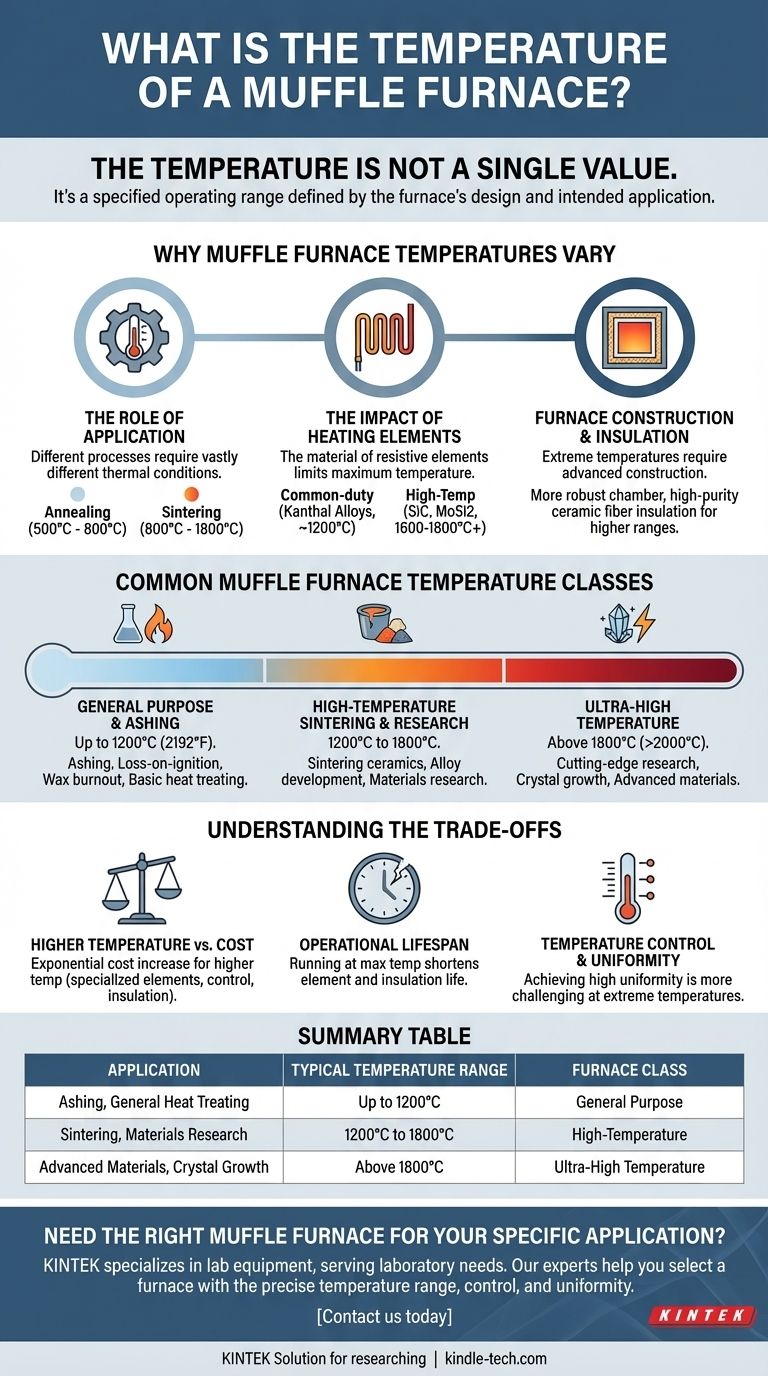

Why Muffle Furnace Temperatures Vary

The wide range of temperatures cited for muffle furnaces stems from their diverse designs and uses. The maximum achievable temperature is a deliberate engineering choice, not an arbitrary number. It is dictated by the specific process the furnace was built to perform.

The Role of the Application

The primary driver for a furnace's temperature range is its intended task. Different material processes require vastly different thermal conditions.

For example, processes like annealing or some heat treatments may only require a range of 500°C to 800°C. In contrast, sintering ceramics or metals demands much higher temperatures, typically from 800°C up to 1800°C.

The Impact of Heating Elements

Modern electric muffle furnaces rely on resistive heating elements to generate heat. The material used for these elements is the main limiting factor for the furnace's maximum temperature.

Common-duty furnaces (up to ~1200°C) often use Kanthal (FeCrAl) alloys. High-temperature models require more exotic and expensive elements like Silicon Carbide (SiC) for use up to 1600°C or Molybdenum Disilicide (MoSi2) for temperatures of 1800°C and above.

Furnace Construction and Insulation

Reaching and maintaining extreme temperatures requires specialized construction. A furnace designed for 1800°C needs significantly more advanced, high-purity ceramic fiber insulation and a more robust chamber structure than a 1100°C model to operate safely and efficiently.

Understanding the Trade-offs

Choosing a furnace is not as simple as picking the one with the highest temperature. Higher performance comes with significant trade-offs in cost and operation.

Higher Temperature vs. Cost

The relationship between maximum temperature and cost is exponential. A furnace capable of 1700°C can be several times more expensive than a 1200°C model due to the high cost of its specialized heating elements, power control systems, and advanced insulation.

Operational Lifespan

Consistently running a furnace at its absolute maximum rated temperature will shorten the lifespan of its heating elements and insulation. For longevity, it is wise to select a furnace with a maximum temperature slightly above your most common operating temperature.

Temperature Control and Uniformity

The temperature setpoint is the target temperature you program, but temperature uniformity—the consistency of temperature throughout the chamber—is equally critical. Achieving high uniformity becomes more challenging at extreme temperatures, and it is a key differentiator between low-cost and high-performance models.

Common Muffle Furnace Temperature Classes

To simplify the landscape, muffle furnaces can be grouped into general performance tiers based on their maximum temperature.

General Purpose & Ashing (Up to 1200°C)

This is the most common and versatile class of muffle furnace, found in most general-testing laboratories. It is ideal for applications like ashing, loss-on-ignition, wax burnout, and basic heat treating of metals. Furnaces in this category typically max out between 1100°C and 1200°C (2192°F).

High-Temperature Sintering & Research (1200°C to 1800°C)

These furnaces are built for materials science research and small-scale production of advanced materials. They are used for sintering technical ceramics, developing alloys, and other high-temperature processing. Models in this class commonly offer maximum temperatures of 1500°C, 1700°C, or 1800°C.

Ultra-High Temperature (Above 1800°C)

This is a highly specialized category for cutting-edge research on materials like zirconia or for specific crystal growth applications. These furnaces can exceed 2000°C (3632°F) but are less common and come with extreme operational complexity and cost.

Selecting the Right Furnace for Your Application

Choosing the correct furnace requires matching its capabilities directly to your scientific or industrial goal.

- If your primary focus is ashing, burn-off, or general heat treating: A cost-effective furnace with a maximum temperature of 1100°C to 1200°C is the correct choice.

- If your primary focus is sintering advanced ceramics or metallurgical research: You will need a high-temperature model rated for at least 1500°C to 1800°C.

- If your primary focus is precise, lower-temperature annealing: Prioritize a furnace with excellent temperature control and uniformity over a high maximum temperature.

Ultimately, selecting the right muffle furnace means clearly defining your process requirements first and then choosing the instrument engineered to meet them.

Summary Table:

| Application | Typical Temperature Range | Furnace Class |

|---|---|---|

| Ashing, General Heat Treating | Up to 1200°C | General Purpose |

| Sintering, Materials Research | 1200°C to 1800°C | High-Temperature |

| Advanced Materials, Crystal Growth | Above 1800°C | Ultra-High Temperature |

Need the right muffle furnace for your specific application? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select a furnace with the precise temperature range, control, and uniformity your work demands—ensuring efficiency, safety, and longevity. Contact us today to discuss your requirements and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Which metals cannot be hardened by heat treatment? Understand the limits of thermal hardening.

- What is the difference between a muffle furnace and a normal furnace? Ensuring Sample Purity with Indirect Heating

- What temperature is required for calcination? Master Material-Specific Thermal Decomposition

- How does a muffle work? Achieve Clean, Contamination-Free Heating for Your Lab

- What is the significance of the muffle furnace? Achieve Purity and Precision in High-Temperature Processing