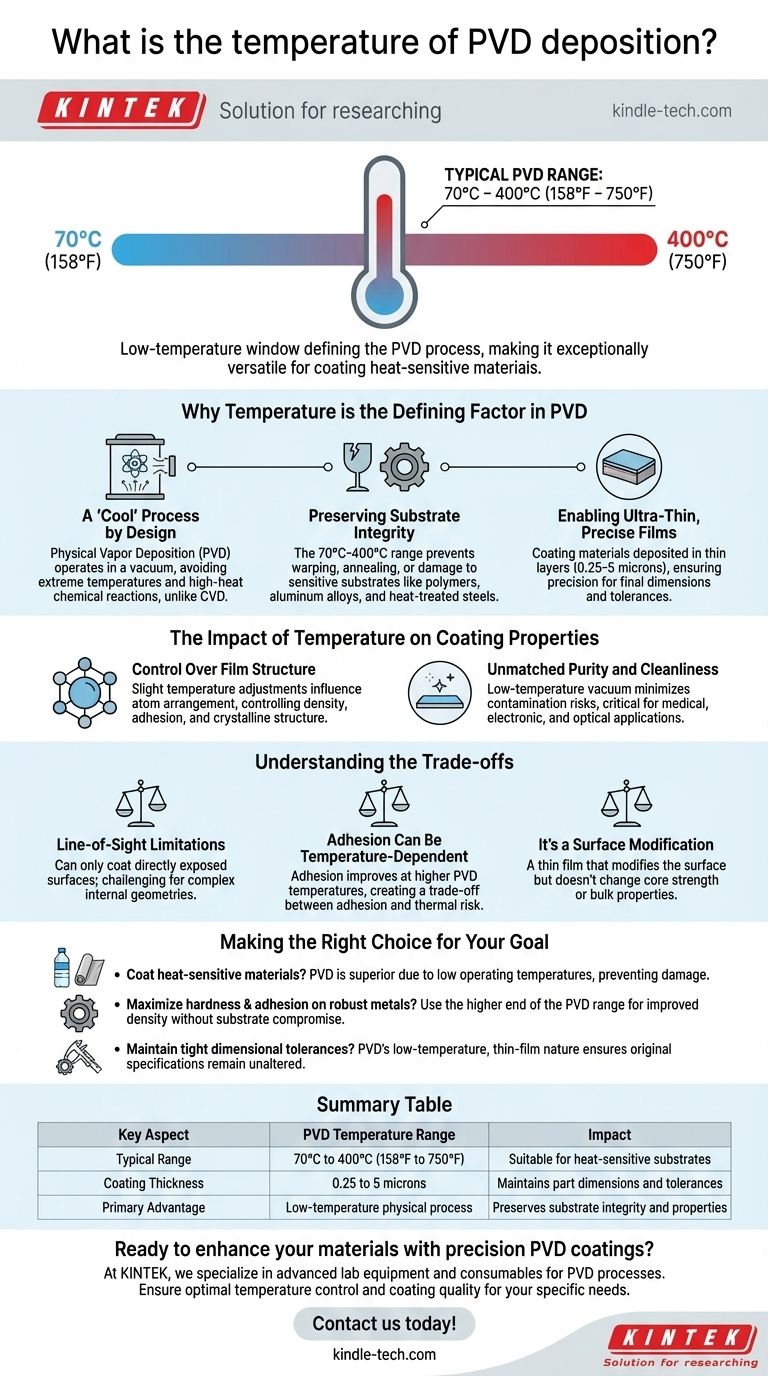

The typical temperature for a Physical Vapor Deposition (PVD) process ranges from 70°C to approximately 400°C (158°F to 750°F). This relatively low-temperature window is a defining characteristic of the PVD process. It is precisely this feature that makes it exceptionally versatile and suitable for coating materials, including plastics and other heat-sensitive substrates, that would be damaged by higher-temperature methods.

While many factors define a coating's quality, temperature is the critical variable that makes PVD uniquely capable. Its low-heat nature is not a limitation but a core advantage, enabling the application of high-performance thin films onto an unparalleled range of materials without altering their fundamental properties.

Why Temperature is the Defining Factor in PVD

The effectiveness of PVD is intrinsically linked to its operation within a controlled, low-temperature vacuum environment. This is not an incidental detail but a central design principle that distinguishes it from other coating methods.

A "Cool" Process by Design

PVD is a line-of-sight deposition technique where a solid material is vaporized in a vacuum and deposited atom by atom onto a substrate. Unlike chemical vapor deposition (CVD), which relies on high-heat chemical reactions, PVD is a physical process.

This fundamental difference means PVD avoids the extreme temperatures that can warp, anneal, or otherwise damage the part being coated.

Preserving Substrate Integrity

The 70°C to 400°C range is well below the melting or deformation point of most engineering materials. This allows for the successful coating of temperature-sensitive substrates.

This includes polymers, aluminum alloys, and heat-treated steels whose carefully engineered bulk properties would be compromised by excessive heat.

Enabling Ultra-Thin, Precise Films

Because the substrate remains stable and cool, the coating material can be deposited in extremely thin and uniform layers. PVD coatings typically range from 0.25 to 5 microns in thickness.

This precision ensures that the final dimensions and tolerances of an engineered part remain unchanged, a critical requirement in high-precision industries.

The Impact of Temperature on Coating Properties

The specific temperature chosen within the PVD range is a key parameter used to fine-tune the final characteristics of the coating itself.

Control Over Film Structure

Slight adjustments in substrate temperature directly influence how the deposited atoms arrange themselves. This allows engineers to control the density, adhesion, and crystalline structure of the film.

A higher temperature within the PVD window often results in a denser, harder film with stronger adhesion to the substrate.

Unmatched Purity and Cleanliness

Operating in a vacuum at low temperatures minimizes the risk of contamination from the atmosphere or from unwanted chemical side-reactions.

This results in an exceptionally pure and clean coating, which is essential for medical, electronic, and optical applications where contamination can cause component failure.

Understanding the Trade-offs

While its low-temperature nature is a primary advantage, PVD has practical limitations that are important to understand.

Line-of-Sight Limitations

PVD is a "line-of-sight" process, meaning it can only coat surfaces that are directly exposed to the vapor source.

Coating complex internal geometries or deeply recessed features can be challenging and may require complex fixturing and part rotation during the process.

Adhesion Can Be Temperature-Dependent

While PVD works at low temperatures, coating adhesion can often be improved by processing at the higher end of the PVD temperature range (e.g., 350-400°C).

This creates a trade-off: for the most sensitive substrates, one might have to accept slightly lower adhesion to prevent any risk of thermal damage.

It's a Surface Modification

PVD creates an exceptionally durable surface, but it is fundamentally a thin film. It does not change the core strength or bulk properties of the underlying material.

This is typically a benefit, as it preserves the substrate's original engineering characteristics, but it means PVD cannot be used to strengthen a part from the inside out.

Making the Right Choice for Your Goal

The ideal deposition temperature is dictated by your substrate material and desired performance characteristics.

- If your primary focus is coating temperature-sensitive materials like plastics or aluminum: PVD is the superior choice due to its low operating temperatures, preventing substrate damage.

- If your primary focus is achieving maximum coating hardness and adhesion on robust metals: You can utilize the higher end of the PVD temperature range to improve film density without compromising the substrate.

- If your primary focus is maintaining tight dimensional tolerances on a finished part: PVD's low-temperature, thin-film nature ensures that the part's specifications remain completely unaltered.

Ultimately, understanding the PVD temperature range empowers you to leverage its unique advantages for enhancing surface performance without compromising your underlying material.

Summary Table:

| Key Aspect | PVD Temperature Range | Impact |

|---|---|---|

| Typical Range | 70°C to 400°C (158°F to 750°F) | Suitable for heat-sensitive substrates |

| Coating Thickness | 0.25 to 5 microns | Maintains part dimensions and tolerances |

| Primary Advantage | Low-temperature physical process | Preserves substrate integrity and properties |

Ready to enhance your materials with precision PVD coatings?

At KINTEK, we specialize in providing advanced lab equipment and consumables for PVD processes. Our solutions ensure optimal temperature control and coating quality for your specific substrate needs—whether you're working with plastics, metals, or other sensitive materials.

Contact us today to discuss how our expertise can help you achieve superior surface performance without compromising your material's integrity!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process