In a practical sense, the temperature your components will experience during a Physical Vapor Deposition (PVD) process typically ranges from 70°C to just under 400°C (158°F to 750°F). However, the concept of "temperature" within a PVD plasma is more complex than a single number. The true answer involves understanding the difference between the heat of the source material, the energy of the plasma particles, and the carefully controlled temperature of your part.

While the source material is vaporized at thousands of degrees, the PVD process is fundamentally a line-of-sight, low-temperature coating method. The critical temperature is that of your component (the substrate), which is carefully controlled to preserve its structural integrity and dimensions.

Deconstructing "Temperature" in a PVD Plasma

The term "plasma temperature" can be misleading. In the vacuum of a PVD chamber, it is more accurate to consider three distinct thermal zones, only one of which directly affects your part.

The Vapor Source Temperature (Extremely Hot)

To create the coating vapor, a solid source material (known as a target) is bombarded with high energy. This can be done via an electric arc or an electron beam.

This process heats the target material to its evaporation point, which can be thousands of degrees Celsius, turning the solid directly into a gas.

The Plasma's Particle Energy (A Misleading Average)

The resulting vapor cloud, or plasma, consists of different particles with vastly different effective temperatures.

Electrons in the plasma are extremely energetic and could be considered millions of degrees hot. However, the much heavier ions and neutral atoms that will form the coating are significantly cooler. An "average" temperature of these particles is not a meaningful metric.

The Substrate Temperature (The Only Number That Matters)

This is the temperature that your component—the substrate—reaches during the coating process. This is the 70°C to 400°C range.

This temperature is not a byproduct; it is a critical process parameter. It is actively controlled and monitored to ensure the coating adheres properly without damaging the part.

Why PVD is Considered a "Low-Temperature" Process

Despite the extreme heat at the source, PVD is valued for being a "cool" coating process, especially when compared to methods like Chemical Vapor Deposition (CVD), which can exceed 1000°C.

A Controlled Vacuum Environment

PVD occurs in a high vacuum, which severely limits heat transfer through convection. Heat is primarily introduced by the condensing coating atoms and, in some cases, radiant heaters used to bring the substrate to the optimal temperature.

Preserving Material Properties

This precise temperature control is the reason PVD can be used on a wide variety of materials. It operates well below the tempering or annealing temperatures of most steels and alloys.

This ensures that precision-machined parts maintain their critical dimensions, hardness, and internal stress characteristics after being coated.

Understanding the Trade-offs

Choosing the right temperature is a balance between coating quality and substrate integrity. It is not always best to run the process as cool as possible.

Temperature vs. Adhesion and Density

Generally, a higher (but still safe) substrate temperature promotes better adhesion and results in a denser, more uniform coating structure. The added thermal energy helps the deposited atoms arrange themselves into a more stable film.

Substrate Material Limitations

The "low-temperature" nature of PVD is relative. While 400°C is cool for tool steel, it is destructive to most polymers and can negatively affect certain aluminum alloys. The substrate material dictates the absolute upper limit of the process window.

Line-of-Sight Heating

Because PVD is a line-of-sight process, parts with complex geometries can experience uneven heating and coating thickness. This often requires sophisticated rotating fixtures within the chamber to ensure all surfaces are treated uniformly.

Making the Right Choice for Your Substrate

The ideal PVD process temperature is determined entirely by the substrate material and the desired coating properties.

- If your primary focus is coating hardened tool steels: You can likely use the higher end of the temperature range (~350-400°C) to achieve maximum coating hardness and adhesion without affecting the steel's temper.

- If your primary focus is coating aluminum or other sensitive alloys: The process temperature must be kept below the material's annealing or aging temperature, often in the 150-250°C range.

- If your primary focus is coating medical-grade polymers or plastics: You will require a specialized low-temperature PVD process, often operating below 100°C, to prevent any melting, warping, or outgassing.

Understanding that substrate temperature is the critical, controllable variable empowers you to specify the right PVD process for your components.

Summary Table:

| PVD Process Temperature Zone | Typical Range | Why It Matters |

|---|---|---|

| Vapor Source (Target) | Thousands of °C | Creates the coating vapor |

| Plasma Particle Energy | Varies (Misleading) | Not a direct measure of heat on the part |

| Substrate (Your Part) | 70°C to 400°C | Critical: Controlled to preserve part integrity |

Ensure your lab's precision parts are coated correctly without compromising their properties. KINTEK specializes in lab equipment and consumables, providing the precise thermal control needed for successful PVD processes. Our expertise helps you select the right parameters to protect your substrates—from hardened steels to sensitive alloys and polymers.

Contact KINTEK today to discuss your specific coating requirements and achieve optimal adhesion and performance.

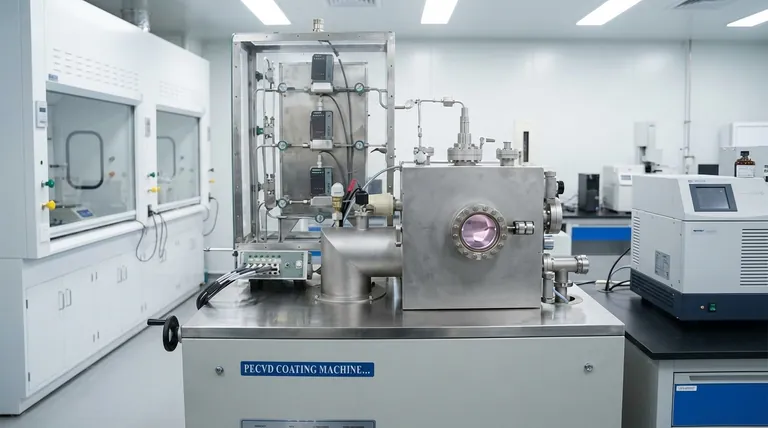

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films