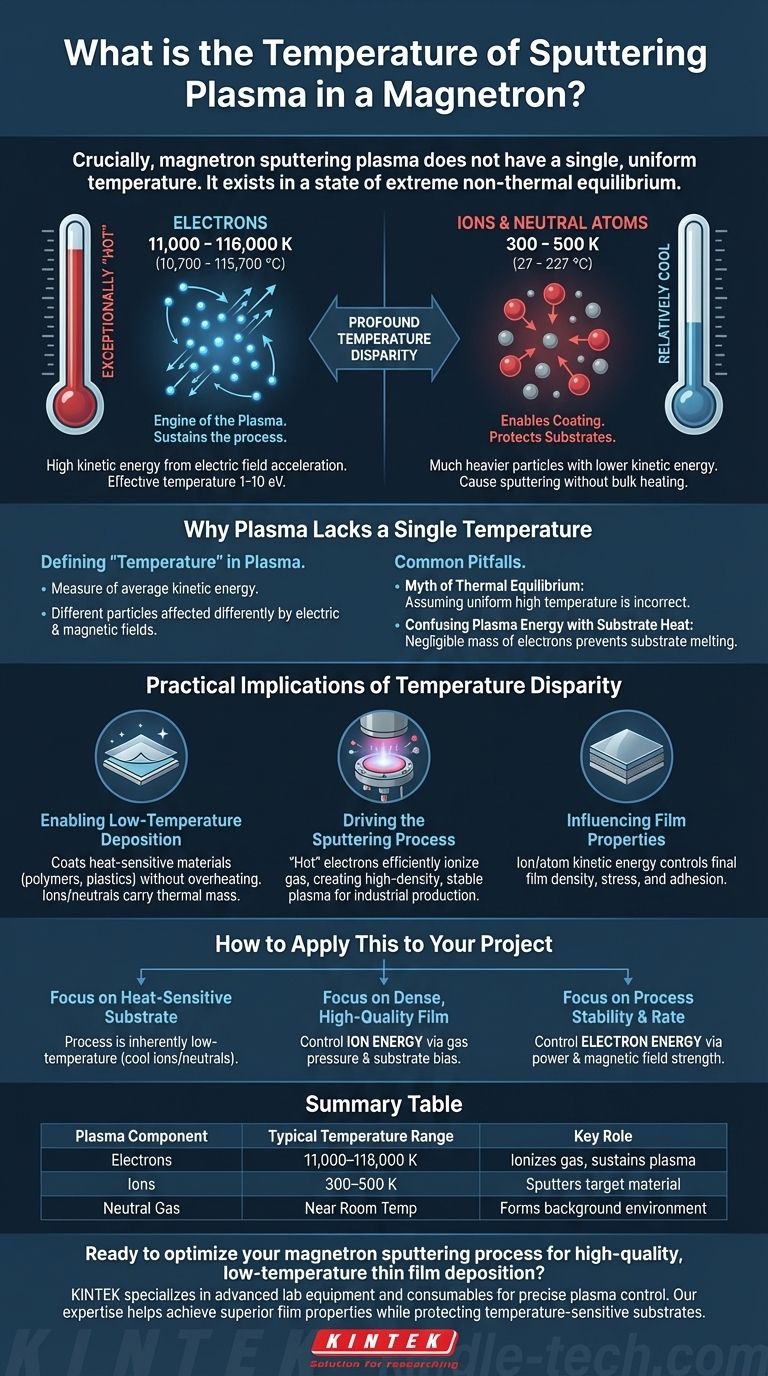

Crucially, magnetron sputtering plasma does not have a single, uniform temperature. Instead, it exists in a state of extreme non-thermal equilibrium, where different particles possess vastly different kinetic energies. While the heavy particles like ions and neutral gas atoms remain relatively cool—often only slightly above room temperature—the free electrons are exceptionally "hot," with an effective temperature equivalent to tens of thousands of degrees Celsius.

The core concept to grasp is that sputtering plasma operates with a profound temperature disparity. The incredibly high energy of the electrons is what sustains the plasma, while the relative coolness of the much heavier ions and atoms is what allows for the deposition of high-quality thin films onto temperature-sensitive materials without damaging them.

Why Plasma Lacks a Single Temperature

The concept of a single temperature only applies to systems in thermal equilibrium, where energy is evenly distributed among all particles. Sputtering plasma is the exact opposite of this.

Defining "Temperature" in Plasma

In physics, temperature is a measure of the average kinetic energy of a group of particles.

Because the electric and magnetic fields in a magnetron chamber affect different particles in drastically different ways, we must consider the "temperature" of each particle population separately.

The Role of Electrons (The "Hot" Component)

Electrons are thousands of times lighter than atoms. When a strong voltage is applied, they are accelerated to tremendous speeds, gaining immense kinetic energy.

This high energy is why electrons are the engine of the plasma. Their collisions with neutral gas atoms knock off other electrons, creating the ions needed to sustain the process. The effective temperature of these electrons is typically 1 to 10 electron-volts (eV), which corresponds to a staggering 11,000 to 116,000 K (approximately 10,700 to 115,700 °C).

The Behavior of Ions (The "Cool" Component)

Ions, being essentially gas atoms with a missing electron, are much heavier. They cannot be accelerated to the same speeds as electrons by the electric field.

As a result, their kinetic energy and corresponding temperature are far lower, often in the range of 300 to 500 K (approximately 27 to 227 °C). They are energetic enough to sputter the target material upon impact but cool enough not to cause significant bulk heating of the substrate.

The Neutral Gas Background (The "Cold" Component)

The vast majority of the gas in the chamber (typically argon) remains neutral and is not directly accelerated by the electric fields.

This background gas stays near room temperature, acting as a cold environment through which the sputtered atoms travel from the target to the substrate.

Common Pitfalls to Avoid

Understanding this temperature imbalance is critical because it prevents common but significant misunderstandings of the sputtering process.

The Myth of Thermal Equilibrium

The most frequent mistake is assuming the plasma has one uniform, high temperature. This is fundamentally incorrect and leads to flawed reasoning about process control and its effect on the substrate.

Confusing Plasma Energy with Substrate Heat

One might assume that a plasma with 10,000 K electrons would instantly melt any substrate. However, the actual heat delivered to the substrate is much lower.

This is because the electrons have negligible mass, and the heat load is primarily determined by the "cooler" but much heavier ions and condensing atoms striking the surface.

Practical Implications of Temperature Disparity

This unique non-equilibrium state is not a bug; it is the central feature that makes magnetron sputtering so effective.

Enabling Low-Temperature Deposition

The primary benefit is the ability to coat heat-sensitive materials like polymers or plastics. Because the particles carrying the most thermal mass (ions and neutrals) are cool, the substrate does not overheat.

Driving the Sputtering Process

The "hot" electrons are essential for efficiently ionizing the sputtering gas. This creates a high-density plasma at low pressure, ensuring a stable and rapid deposition process suitable for industrial production.

Influencing Film Properties

The kinetic energy of the arriving ions and sputtered atoms—related to their "temperature"—directly influences the final film's density, stress, and adhesion. Controlling this energy is key to controlling the material's properties.

How to Apply This to Your Project

Your process goals should dictate which particle energies you focus on controlling.

- If your primary focus is coating a heat-sensitive substrate: You can proceed with confidence, knowing the process is inherently low-temperature because the heavy ions and neutral atoms are relatively cool.

- If your primary focus is achieving a dense, high-quality film: Concentrate on controlling the ion energy, which is managed through parameters like gas pressure and substrate bias, not by trying to alter the overall plasma "temperature."

- If your primary focus is process stability and deposition rate: Your attention should be on the factors that influence electron energy and plasma density, such as power and magnetic field strength.

Understanding this fundamental temperature imbalance is the key to mastering the magnetron sputtering process and deliberately controlling the properties of your final film.

Summary Table:

| Plasma Component | Typical Temperature Range | Key Role in Sputtering |

|---|---|---|

| Electrons (Hot) | 11,000 – 116,000 K (1-10 eV) | Ionizes gas, sustains plasma |

| Ions (Cool) | 300 – 500 K (27-227 °C) | Sputters target material |

| Neutral Gas (Cold) | Near room temperature | Forms background environment |

Ready to optimize your magnetron sputtering process for high-quality, low-temperature thin film deposition? KINTEK specializes in advanced lab equipment and consumables for precise plasma control. Our expertise helps researchers and manufacturers achieve superior film properties while protecting temperature-sensitive substrates. Contact us today to discuss how our solutions can enhance your coating applications!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process