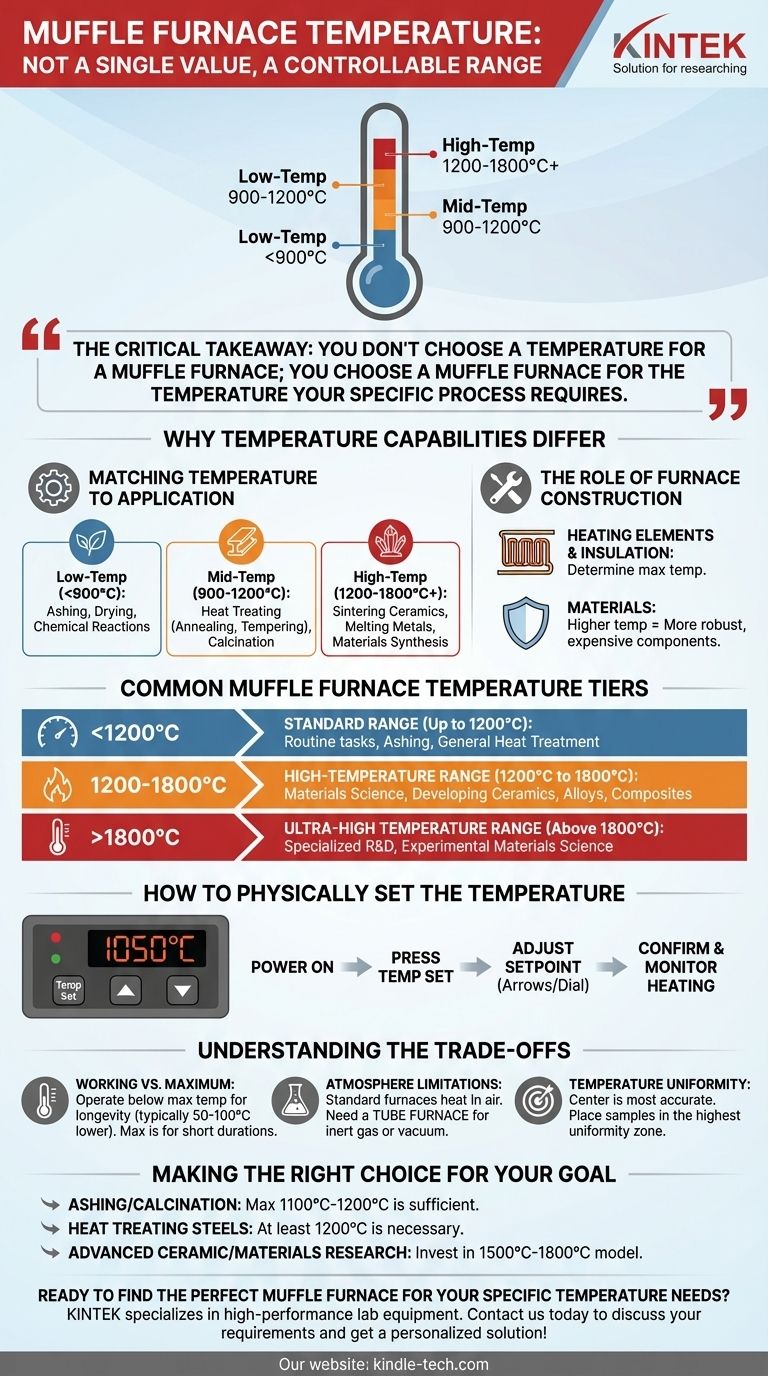

The temperature setting of a muffle furnace is not a single value but a controllable range that is entirely dependent on the specific model. While some furnaces are designed for lower-temperature work up to 900°C, high-performance models can be set to operate at temperatures well over 1800°C for specialized applications.

The critical takeaway is that you don't choose a temperature for a muffle furnace; you choose a muffle furnace for the temperature your specific process requires. The furnace's construction and heating elements dictate its operational range.

Why Temperature Capabilities Differ

The core reason for the wide variety of muffle furnace models is that different scientific and industrial processes require vastly different thermal conditions. The furnace is a tool, and you must select the right tool for the job.

Matching Temperature to Application

A furnace's temperature range is directly tied to its intended use. Processes like ashing, annealing, and sintering occur at fundamentally different temperatures.

- Low-Temperature Processes (<900°C): Applications like drying, ashing organic materials, and some chemical reactions fall into this category.

- Mid-Temperature Processes (900°C - 1200°C): This is a common range for heat-treating metals like quenching, annealing, and tempering, as well as for the calcination of many materials.

- High-Temperature Processes (1200°C - 1800°C+): Sintering advanced ceramics, melting certain metals, and conducting high-temperature materials synthesis demand furnaces built for these extreme conditions.

The Role of Furnace Construction

A furnace's maximum temperature is limited by the materials used to build it. The type of heating element and insulation material are the primary determining factors.

A furnace designed for 1200°C will use different, less expensive components than one engineered to withstand 1800°C safely and repeatedly. This is why higher-temperature furnaces are significantly more expensive.

Common Muffle Furnace Temperature Tiers

Muffle furnaces are generally grouped into tiers based on their maximum achievable temperature.

Standard Range (Up to 1200°C)

These are the most common and cost-effective furnaces. They are workhorses in many labs for routine tasks like ashing, general heat treatment, and materials analysis that do not require extreme heat.

High-Temperature Range (1200°C to 1800°C)

These specialized units are required for more demanding applications. They are essential in fields like materials science for developing and testing new ceramics, alloys, and composites.

Ultra-High Temperature Range (Above 1800°C)

Furnaces capable of exceeding 1800°C, some reaching over 2000°C, are reserved for highly specialized experimental research. They push the boundaries of materials science and are found in advanced R&D facilities.

How to Physically Set the Temperature

Operating the furnace involves interacting with its controller. While older models used analog dials, modern furnaces use precise digital controllers.

Using the Digital Controller

The process is typically straightforward. After ensuring the furnace is safely wired and powered on, you access the temperature setting mode.

This usually involves pressing a 'Temperature Set' or similar button. You can then use arrow keys or a dial to adjust the numerical setpoint to your desired temperature.

Monitoring the Heating Process

Once the setpoint is confirmed, the furnace powers on its heating elements. The controller's display will show the actual internal temperature as it rises to meet your setpoint. Indicator lights and an ammeter often confirm that the system is drawing power and heating correctly.

Understanding the Trade-offs

Selecting and using a muffle furnace requires understanding its limitations to ensure safety, longevity, and accurate results.

Working vs. Maximum Temperature

A furnace has a maximum temperature and a continuous working temperature. The maximum temperature should only be used for short durations. For longevity and stability, the furnace should be operated at or below its specified continuous working temperature, which is typically 50°C to 100°C lower than the maximum.

Atmosphere Limitations

A standard muffle furnace heats in the presence of air. The "muffle" design isolates the sample from direct contact with the heating elements but does not control the atmosphere. If your process requires an inert gas (like argon) or a vacuum, you need a different type of furnace, such as a tube furnace.

Temperature Uniformity

The temperature in the exact center of the furnace chamber is often the most accurate and stable. The temperature near the door or walls may be slightly lower. For precise work, it's important to place the sample in the zone of highest uniformity.

Making the Right Choice for Your Goal

Your choice must be driven by the most demanding temperature your work requires, with a safety margin built in.

- If your primary focus is ashing or basic calcination: A furnace with a maximum temperature of 1100°C to 1200°C is a sufficient and cost-effective choice.

- If your primary focus is heat treating common steels: A furnace capable of reaching at least 1200°C will provide the necessary range for processes like annealing and tempering.

- If your primary focus is advanced ceramic sintering or materials research: You must invest in a high-temperature model (1500°C to 1800°C) specifically designed for your material's requirements.

Ultimately, successfully using a muffle furnace begins with selecting a model whose temperature capabilities align perfectly with your scientific or industrial objective.

Summary Table:

| Temperature Tier | Maximum Range | Common Applications |

|---|---|---|

| Standard Range | Up to 1200°C | Ashing, drying, basic heat treatment |

| High-Temperature | 1200°C - 1800°C | Sintering ceramics, advanced materials research |

| Ultra-High Temp | Above 1800°C | Specialized R&D, experimental materials science |

Ready to find the perfect muffle furnace for your specific temperature needs? KINTEK specializes in high-performance lab equipment, offering a range of muffle furnaces designed for precision, durability, and safety. Whether you're working on ashing, sintering, or advanced materials research, our experts can help you select the right model to enhance your lab's efficiency and accuracy. Contact us today to discuss your requirements and get a personalized solution!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the alternative to a laboratory oven? Find the Right Heating Tool for Your Lab

- What is the heating element of a muffle furnace? The Engine for High-Temp Precision

- What is a furnace used in a chemistry lab? A Guide to High-Temperature Material Transformation

- Why do we use muffle furnace? For Unmatched Purity and Precision in High-Temp Processing

- What is a muffle furnace? The Definitive Tool for Contaminant-Free, Precise Heating