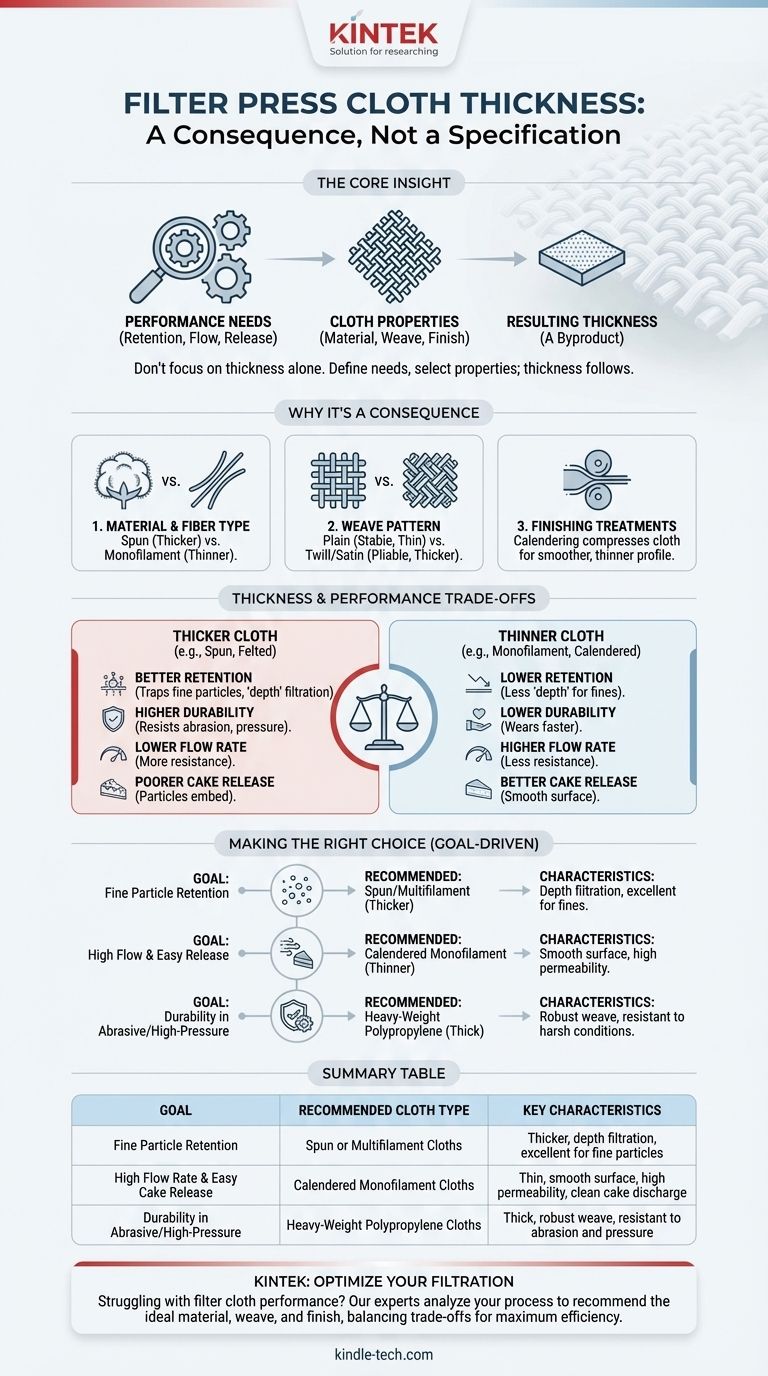

There is no single standard thickness for a filter press cloth. The thickness is a resulting characteristic, not a primary specification, and it can range significantly from as thin as 0.3 mm for fine monofilament cloths to over 3 mm for heavy-duty, felted materials. The correct thickness for your operation is determined entirely by the material, weave, and finish required to achieve your specific filtration goals.

The critical insight is to stop focusing on thickness as a standalone metric. Instead, you must define your performance needs—such as particle retention, flow rate, and cake release—and select a cloth whose properties (material, weave, finish) meet those needs. The resulting thickness is simply a byproduct of that correct selection.

Why Thickness is a Consequence, Not a Cause

Thinking of thickness as a primary selection criterion is a common mistake. It is the outcome of several more fundamental design choices that directly impact the cloth's performance.

The Role of Material and Fiber Type

The fibers used to create the yarn are the foundational building block. A cloth made from spun fibers (short, twisted fibers like cotton) will be thicker, fuzzier, and better for capturing extremely fine particles through depth filtration. In contrast, a cloth woven from monofilament (single, smooth, plastic-like strands) will be thinner, smoother, and offer excellent cake release.

The Impact of Weave Pattern

The way the yarns are interwoven creates the fabric's structure. A simple plain weave produces a relatively thin and stable cloth. A more complex twill or satin weave creates a more pliable, denser, and typically thicker fabric that is more resistant to blinding (clogging).

The Influence of Finishing Treatments

After weaving, cloths often undergo finishing processes. Calendering involves passing the fabric through heated rollers under high pressure. This process compresses the cloth, making it thinner, less permeable, and much smoother, which dramatically improves cake release.

How Thickness Influences Critical Performance

While you shouldn't select a cloth based on thickness, understanding how it correlates with performance helps in diagnosing issues and specifying new cloths.

Impact on Particle Retention

Generally, a thicker cloth, especially one made of spun or multifilament fibers, provides more "depth." This tortuous path is more effective at trapping very fine particles that might otherwise pass through a thinner, more uniform monofilament screen.

Impact on Flow Rate (Permeability)

Thickness is often inversely related to flow rate. A thicker fabric presents more resistance to the liquid passing through it, resulting in lower permeability and longer cycle times. This is a fundamental trade-off against finer particle retention.

Impact on Cake Release

Thicker, "fuzzy" cloths can allow filter cake particles to embed deep within the fabric, making cake discharge difficult and incomplete. Thinner, smoother, and calendared cloths provide a superior surface for clean cake release, which is critical for efficient, automated operations.

Impact on Durability and Lifespan

Heavier, thicker cloths are generally more robust. They can better withstand high filtration pressures, mechanical stress from plate shifters, and abrasive slurries, often resulting in a longer operational life.

Understanding the Trade-offs

Selecting a filter cloth is always an exercise in balancing competing priorities. There is no single "best" cloth, only the best cloth for a specific application.

Fine Filtration vs. Flow Rate

To capture finer particles, you often need a denser, less permeable cloth, which is frequently thicker. This will almost always reduce your flow rate and extend cycle times.

Durability vs. Cake Release

The most durable cloths are often heavy-weight and thick, built to withstand abrasion. However, these same properties can impede cake release. A thinner monofilament cloth might offer perfect cake release but wear out quickly if used with an abrasive slurry.

Cost vs. Performance

Specialty cloths with complex weaves, treatments, and thicker constructions are more expensive. You must justify the higher cost with measurable improvements in performance, such as better product quality, longer cloth life, or reduced downtime.

Making the Right Choice for Your Goal

Instead of asking for a specific thickness, define your primary operational goal. This will guide you to the correct combination of material, weave, and finish.

- If your primary focus is capturing very fine particles: Choose spun fiber or multifilament cloths, which will be inherently thicker and provide excellent depth filtration.

- If your primary focus is maximizing flow rate and easy cake release: Prioritize smooth, calendared monofilament cloths, which are typically the thinnest options.

- If your primary focus is durability in an abrasive, high-pressure environment: Select a heavy-weight cloth made from a strong material like polypropylene with a robust weave, which will naturally be thicker.

Ultimately, you must match the cloth's properties to the demands of your process, and the right thickness will follow.

Summary Table:

| Goal | Recommended Cloth Type | Typical Thickness Range | Key Characteristics |

|---|---|---|---|

| Fine Particle Retention | Spun or Multifilament Cloths | 1.5 mm - 3+ mm | Thicker, depth filtration, excellent for fine particles |

| High Flow Rate & Easy Cake Release | Calendered Monofilament Cloths | 0.3 mm - 1.5 mm | Thin, smooth surface, high permeability, clean cake discharge |

| Durability in Abrasive/High-Pressure | Heavy-Weight Polypropylene Cloths | 2 mm - 3+ mm | Thick, robust weave, resistant to abrasion and pressure |

Struggling with filter cloth performance? Let KINTEK's experts guide you to the optimal solution.

Choosing the right filter press cloth is critical for your lab's efficiency and product quality. The wrong cloth can lead to blinding, poor cake release, and extended cycle times.

KINTEK specializes in lab equipment and consumables, providing high-performance filter cloths tailored to your specific slurry and process requirements. We help you balance the trade-offs between particle retention, flow rate, and durability to maximize your filtration outcomes.

We provide:

- Expert Consultation: Our specialists analyze your application to recommend the ideal material, weave, and finish.

- High-Quality Products: Durable, reliable cloths that extend service life and reduce downtime.

- Performance Optimization: Achieve clearer filtrate, faster cycles, and cleaner cake release.

Contact us today for a consultation and let us help you select the perfect filter cloth for your lab's unique needs.

Get in touch with our filtration experts now!

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Vacuum Cold Mounting Machine for Sample Preparation

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid

- What are the factors that affect the filtration of the solution? Master the Key Variables for Optimal Performance

- What are the failures in a hydraulic system? Prevent Costly Downtime with Expert Diagnosis

- What is the lifespan of a filter media? Understand the 3 Types for Optimal Filtration

- What happens if a hydraulic system leaks? Prevent Costly Damage and Safety Hazards