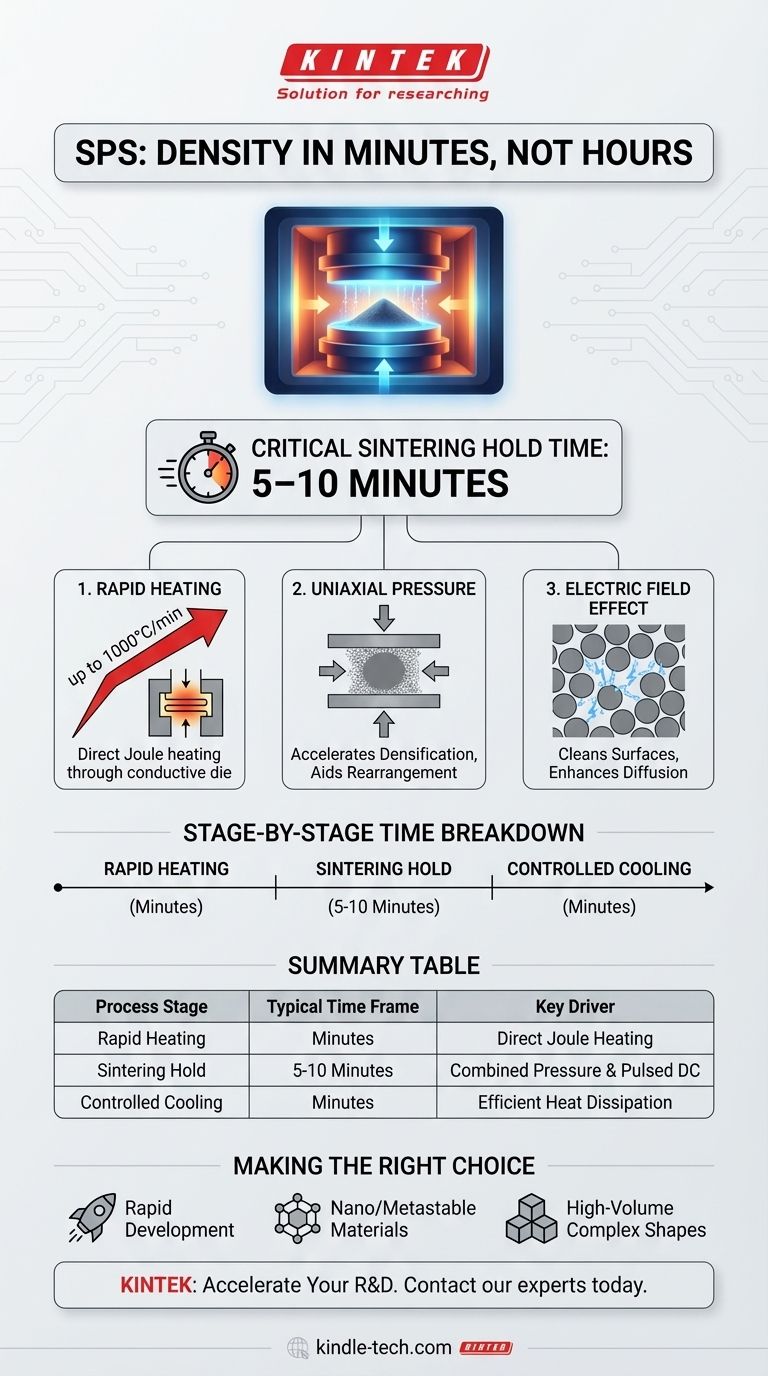

In most cases, the critical sintering hold time for spark plasma sintering (SPS) is just 5 to 10 minutes. This is a dramatic reduction from the hours often required for conventional sintering methods. The entire cycle, including heating and cooling, is exceptionally fast due to the unique way SPS applies energy to the material.

The defining advantage of spark plasma sintering is not merely its speed, but its underlying mechanism. By combining direct Joule heating, high mechanical pressure, and a pulsed electric field, SPS achieves densification in minutes at temperatures often hundreds of degrees lower than traditional furnaces.

How SPS Achieves Unprecedented Speed

The remarkable speed of SPS is not an incremental improvement; it is the result of a fundamentally different approach to heating and consolidating powdered materials. It combines three phenomena simultaneously to accelerate the process.

The Role of Direct Joule Heating

Unlike a conventional furnace that slowly heats a sample with external radiation, SPS passes a high-amperage, pulsed direct current (DC) through the conductive die (typically graphite) and, often, through the sample itself.

This current generates Joule heat—heat produced by electrical resistance—directly within the system. This allows for extremely rapid heating rates, sometimes as high as 1000°C per minute, getting the material to its sintering temperature in a fraction of the time.

The Impact of Uniaxial Pressure

SPS is a pressure-assisted technique, similar to hot pressing. The powdered material is held in a die and compressed between two punches under significant mechanical load.

This constant pressure forces the powder particles together, aiding in particle rearrangement and promoting plastic deformation at contact points. This mechanical assistance significantly accelerates the densification process, reducing the time needed at peak temperature.

The Effect of the Electric Field

The pulsed DC current is believed to do more than just generate heat. The "spark plasma" name refers to the theory that micro-sparks or plasma discharges can occur between individual powder particles.

These discharges can clean particle surfaces by vaporizing impurities and oxides, creating highly active surfaces that bond together more readily. This enhanced atomic diffusion is a key factor that distinguishes SPS from simple hot pressing and contributes to its speed.

A Stage-by-Stage Time Breakdown

The total SPS cycle time is a sum of its efficient stages, each of which is significantly shorter than its conventional counterpart.

Stage 1: Rapid Heating (Minutes)

With heating rates reaching hundreds or even 1000°C/min, reaching the target sintering temperature (e.g., 1500°C) is a matter of minutes. In a conventional furnace, this heating ramp alone could take several hours.

Stage 2: Sintering Hold Time (5-10 Minutes)

This is the critical phase where the material densifies. Because of the combined effects of pressure and direct heating, the material only needs to be held at the peak temperature for 5 to 10 minutes to achieve high density.

Stage 3: Controlled Cooling (Minutes)

Just as heating is rapid, cooling can also be controlled and executed quickly. This shortens the overall process time and can be crucial for preserving specific microstructures, such as those found in nanocrystalline materials.

Understanding the Trade-offs

While exceptionally powerful, the speed and mechanism of SPS come with practical limitations that are important to understand.

Sample Geometry and Size

The process relies on a rigid die and uniaxial pressure. This means SPS is primarily suited for producing simple shapes like discs, cylinders, and rectangular bars. Complex, three-dimensional parts are not feasible with this technique.

Material Conductivity

The efficiency of SPS is highest when the electrical current can pass through the sample material itself, generating uniform internal heat. For highly insulating ceramics, heating occurs indirectly as the current passes only through the graphite die. While still fast, this can lead to thermal gradients and less uniform densification compared to conductive samples.

Equipment and Scalability

SPS systems are specialized, high-cost machines. While ideal for research, development, and production of smaller, high-value components, scaling the process for mass production of large parts is a significant engineering and economic challenge compared to conventional furnace sintering.

Making the Right Choice for Your Goal

SPS is a specialized tool, and its benefits are best realized when applied to the right problem.

- If your primary focus is rapid material development: SPS is the definitive choice for its ability to produce dense samples in minutes, enabling fast iteration and screening of new compositions.

- If you are working with nano-structured or metastable materials: The extremely short hold times and lower sintering temperatures of SPS are critical for preventing grain growth and preserving delicate microstructures.

- If your primary focus is high-volume production of complex shapes: You should consider conventional press-and-sinter methods or additive manufacturing techniques, as SPS is limited in geometry and scale.

Ultimately, the speed of spark plasma sintering is not just an incremental improvement; it is a transformative capability that opens new possibilities in materials science.

Summary Table:

| Process Stage | Typical Time Frame | Key Driver |

|---|---|---|

| Rapid Heating | Minutes | Direct Joule Heating (up to 1000°C/min) |

| Sintering Hold | 5-10 Minutes | Combined Pressure & Pulsed DC Current |

| Controlled Cooling | Minutes | Efficient Heat Dissipation |

Need to rapidly develop new materials or preserve delicate microstructures? KINTEK's advanced spark plasma sintering systems can help you achieve full densification in minutes, not hours. Our lab equipment is designed for researchers and developers working with nanocrystalline or metastable materials. Contact our experts today to discuss how SPS can accelerate your R&D timeline.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What are the parameters for spark plasma sintering? Master Speed, Pressure & Temperature Control

- What are the steps in spark plasma sintering? Achieve Rapid, Low-Temperature Densification

- What are the advantages of SPS? Achieve Superior Material Density and Performance

- What is the SPS process of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification

- What is the difference between hot press and SPS? Choose the Right Sintering Method for Your Lab