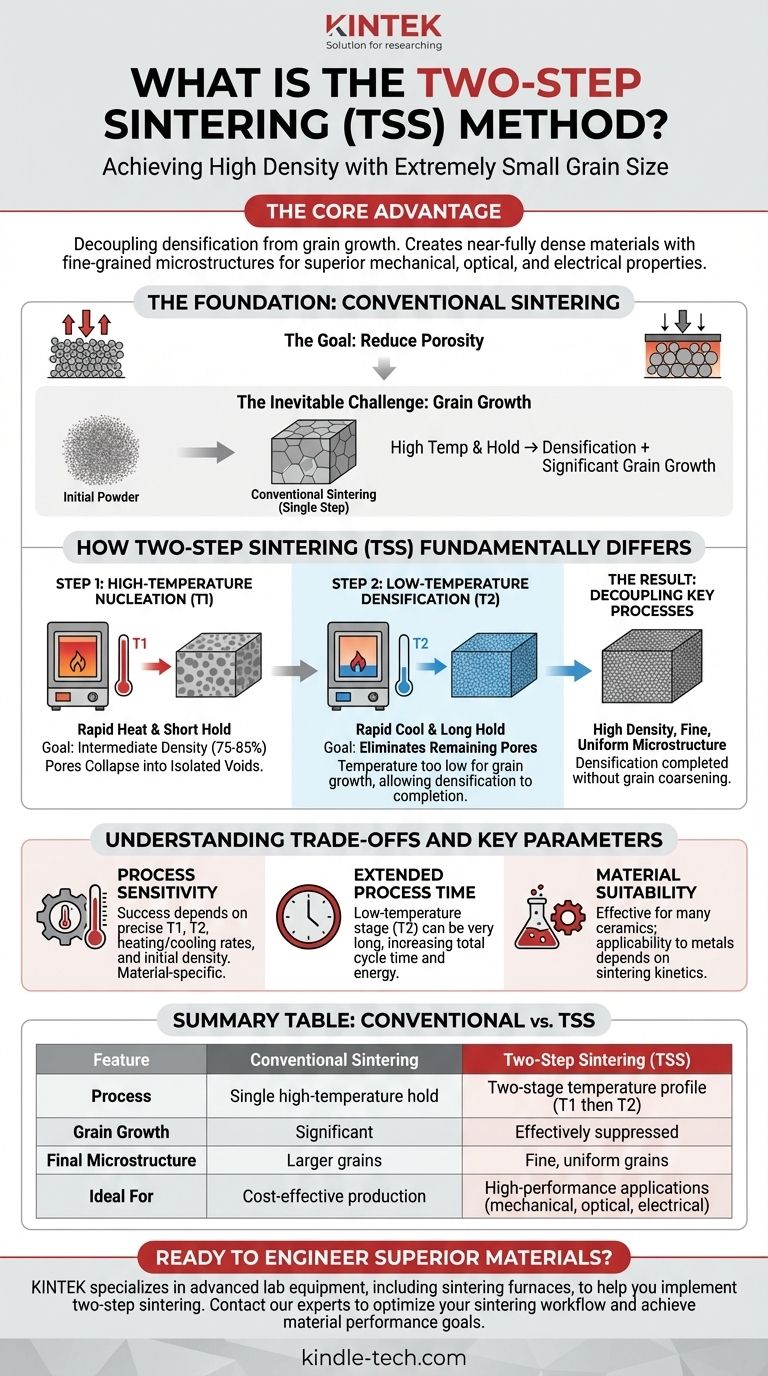

In materials science, two-step sintering (TSS) is a specialized heat treatment process designed to create highly dense ceramic or metallic parts while keeping the internal crystal structure, or grain size, extremely small. Unlike conventional single-step sintering, TSS uses a specific two-stage temperature profile: a short hold at a high temperature (T1) followed by a rapid cool-down and a much longer hold at a lower temperature (T2). This precise control separates the process of densification from the process of grain growth.

The core advantage of two-step sintering is its ability to decouple densification from grain growth. This allows for the creation of near-fully dense materials with a fine-grained microstructure, which is critical for achieving superior mechanical, optical, and electrical properties.

The Foundation: Understanding Conventional Sintering

To appreciate the innovation of two-step sintering, we must first understand the conventional method and its inherent limitations.

The Goal of Sintering

Sintering is the process of compacting a powder into a solid mass using heat and pressure. The temperature is kept below the material's melting point, causing the individual particles to fuse and bond together.

The primary objective is to reduce the porous spaces between particles, creating a dense, solid component. This technique is fundamental in producing ceramic objects and in powder metallurgy for creating complex metal parts.

The Inevitable Challenge: Grain Growth

During conventional, single-step sintering, the material is heated to a high temperature and held there. As the material becomes denser and pores are eliminated, the individual crystalline grains that make up the material naturally begin to grow larger.

For many high-performance applications, this grain growth is undesirable. Larger grains can negatively impact properties like strength, hardness, and fracture toughness.

How Two-Step Sintering (TSS) Fundamentally Differs

Two-step sintering was developed specifically to overcome the grain growth problem inherent in conventional methods. It works by manipulating the kinetics of densification and grain boundary mobility at different temperatures.

Step 1: High-Temperature Nucleation (T1)

The process begins by rapidly heating the compacted powder to a relatively high temperature, T1. The material is held at T1 for only a short time.

The goal of this first step is not to achieve full density. Instead, it aims to quickly reach an intermediate density (typically 75-85%) where the network of pores has largely collapsed into isolated, individual voids.

Step 2: Low-Temperature Densification (T2)

Immediately after the short hold at T1, the material is rapidly cooled to a lower temperature, T2, and held there for an extended period.

At this lower temperature, the driving force for eliminating the remaining isolated pores (densification) is still strong. However, the temperature is too low for the grain boundaries to move easily. This effectively halts significant grain growth while allowing densification to continue to completion.

The Result: Decoupling Key Processes

This two-step process successfully separates the two phenomena. The high-temperature step initiates densification, and the low-temperature step completes it without the penalty of grain coarsening. The final product is a component with high density and a fine, uniform microstructure.

Understanding the Trade-offs and Key Parameters

While highly effective, TSS is not a universal solution and requires precise control to be successful.

Process Sensitivity

The success of TSS is critically dependent on the chosen temperatures (T1 and T2), heating/cooling rates, and the initial density achieved in the first step. These parameters are highly material-specific and must be carefully optimized through experimentation. An incorrect profile can fail to suppress grain growth or result in incomplete densification.

Extended Process Time

The second, low-temperature stage can be very long, sometimes lasting many hours. This can increase the total cycle time and energy consumption compared to some rapid, single-step sintering cycles.

Material Suitability

TSS is exceptionally effective for a wide range of ceramics, including structural ceramics, electrolytes, and bioceramics. Its applicability to different metal powders depends on the specific sintering kinetics of the material system.

Making the Right Choice for Your Goal

The decision to use conventional or two-step sintering depends entirely on the required properties of the final component.

- If your primary focus is maximizing mechanical properties: TSS is the superior choice, as the resulting fine-grained microstructure directly enhances strength, hardness, and fracture resistance.

- If your primary focus is advanced optical or electrical performance: TSS is essential for creating materials like transparent ceramics or high-conductivity solid electrolytes, where both high density and fine grains are critical.

- If your primary focus is high-volume, low-cost production: Conventional single-step sintering may be more economical if the end application can tolerate the larger grain size it typically produces.

Ultimately, two-step sintering provides a powerful tool for precisely engineering a material's microstructure to achieve performance unattainable through conventional methods.

Summary Table:

| Feature | Conventional Sintering | Two-Step Sintering (TSS) |

|---|---|---|

| Process | Single high-temperature hold | Two-stage temperature profile (T1 then T2) |

| Grain Growth | Significant | Effectively suppressed |

| Final Microstructure | Larger grains | Fine, uniform grains |

| Ideal For | Cost-effective production | High-performance applications requiring superior mechanical, optical, or electrical properties |

Ready to engineer superior materials with precise microstructures? KINTEK specializes in advanced lab equipment, including sintering furnaces, to help you implement two-step sintering and other specialized thermal processes. Our expertise supports laboratories in developing high-density, fine-grained ceramic and metal components. Contact our experts today to discuss how we can optimize your sintering workflow and achieve your material performance goals.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations