At its core, an aluminum melting furnace is a specialized industrial tool designed to convert solid aluminum, such as ingots or scrap, into a liquid state. While various heating methods exist, induction furnaces have become a dominant technology for this purpose due to their efficiency, cleanliness, and unique ability to enhance metal quality during the melting process itself.

The primary value of a modern aluminum melting furnace, particularly an induction model, is not just its ability to melt metal. It lies in its capacity to do so with minimal material loss, exceptional purity, and the inherent ability to create uniform, high-quality alloys through electromagnetic stirring.

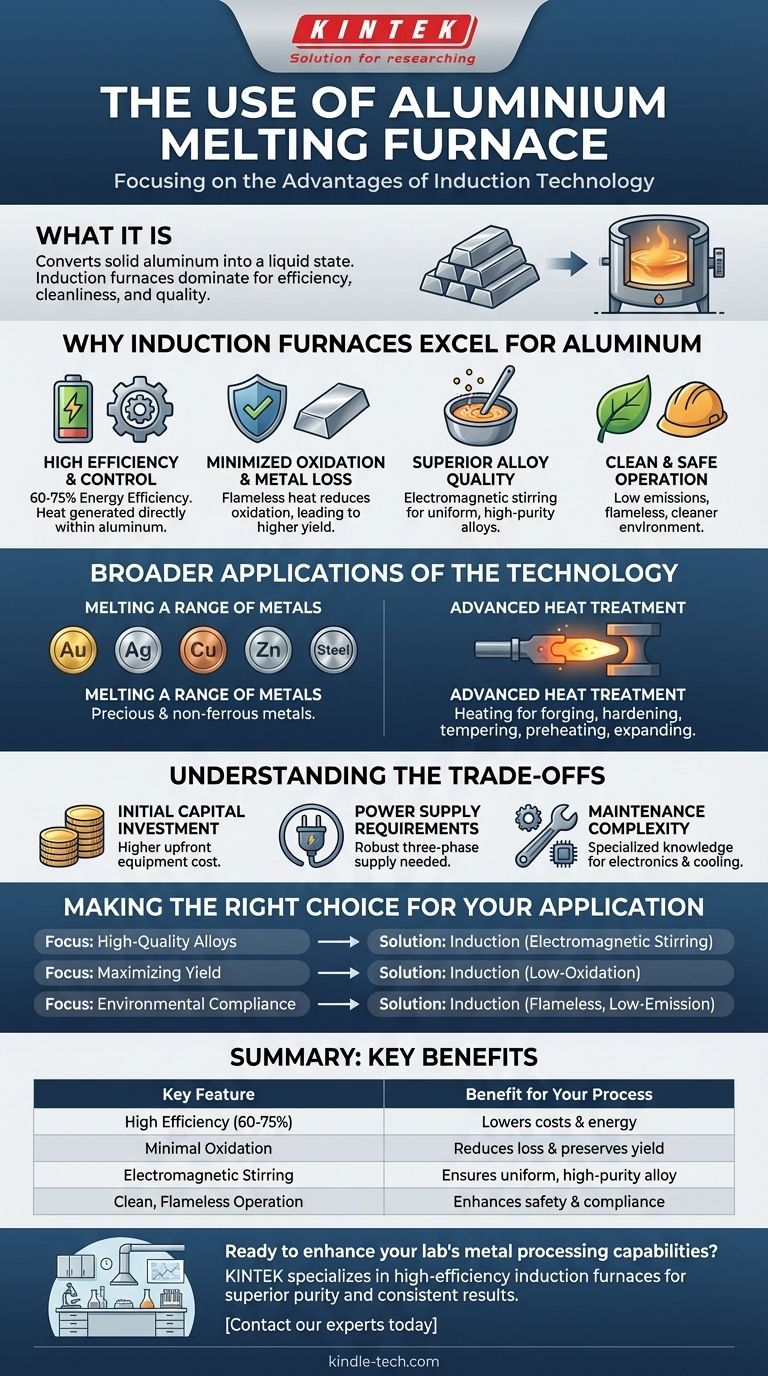

Why Induction Furnaces Excel for Aluminum

The properties of aluminum present specific challenges during melting, such as a high affinity for oxygen. Induction technology directly addresses these challenges, making it an ideal solution.

High Efficiency and Control

An induction furnace operates by using a powerful alternating magnetic field to generate heat directly within the aluminum itself. This method is remarkably efficient, often achieving 60% to 75% energy efficiency, which translates to lower operational costs compared to traditional fuel-fired furnaces.

Minimized Oxidation and Metal Loss

Aluminum readily oxidizes when exposed to air at high temperatures, forming a layer of dross that represents lost material. Because induction heating is flameless and the heat source does not directly contact the metal, oxidation is significantly reduced. This preserves the valuable aluminum and leads to a higher yield.

Superior Alloy Quality

This is arguably the most critical advantage. The electrical field that heats the metal also creates a natural, gentle stirring motion within the molten bath. This electromagnetic stirring is essential for producing aluminum alloys, as it ensures that added elements like silicon, magnesium, or copper are distributed perfectly uniformly, resulting in a high-purity, homogenous end product.

Clean and Safe Operation

Without the combustion of fossil fuels, induction furnaces produce very low emissions and a cleaner working environment. This eliminates the byproducts associated with gas or oil furnaces, contributing to safer operations and easier environmental compliance.

Broader Applications of the Technology

The principle of induction heating is not limited to melting aluminum. Its precision and efficiency make it a versatile tool across many industrial processes.

Melting a Range of Metals

While optimized for aluminum, induction furnaces are used to melt a wide variety of materials. This includes precious metals like gold and silver, other non-ferrous metals like copper and zinc, and even small amounts of steel and stainless steel.

Advanced Heat Treatment

The same technology is applied in processes that require precise heating without melting. This includes heating parts for forging, hardening or tempering steel components (quenching), preheating welds, and expanding pipe ends for fitting.

Understanding the Trade-offs

While highly effective, induction technology is not a universal solution. It's important to understand its specific requirements.

Initial Capital Investment

The technology behind induction furnaces—including the power supply, coils, and control systems—is more complex than that of a simple gas-fired furnace. This typically results in a higher upfront equipment cost.

Power Supply Requirements

Induction furnaces require a robust three-phase electrical supply capable of handling high power demands. This can be a limiting factor for smaller workshops or facilities that lack the necessary electrical infrastructure.

Maintenance Complexity

The sophisticated electronics and water-cooling systems that keep the induction coils from overheating require specialized knowledge for maintenance and repair, which can be more complex than servicing a conventional burner.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your operational goals and priorities.

- If your primary focus is high-quality alloy production: The inherent electromagnetic stirring of an induction furnace is non-negotiable for achieving consistent, uniform results.

- If your primary focus is maximizing material yield: The low-oxidation environment of induction melting will save significant material and cost, especially when working with high volumes.

- If your primary focus is environmental compliance and workplace safety: A flameless, low-emission induction furnace provides a clear advantage over combustion-based systems.

Ultimately, choosing the right furnace technology is less about simply melting metal and more about controlling the quality, efficiency, and final outcome of your entire process.

Summary Table:

| Key Feature | Benefit for Your Process |

|---|---|

| High Efficiency (60-75%) | Lowers operational costs and energy consumption |

| Minimal Oxidation | Reduces material loss and preserves aluminum yield |

| Electromagnetic Stirring | Ensures uniform, high-purity alloy production |

| Clean, Flameless Operation | Enhances workplace safety and environmental compliance |

Ready to enhance your lab's metal processing capabilities? KINTEK specializes in advanced lab equipment, including high-efficiency induction furnaces for aluminum and other metals. Our solutions are designed to deliver superior purity, maximize your material yield, and ensure consistent results for your laboratory or production needs. Contact our experts today to find the perfect furnace for your application!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What frequency is used for induction heating? Select the Right Range for Your Application

- What are the basics of induction melting? A Guide to Fast, Clean Metal Processing

- What is the difference between induction furnace and electric furnace? Uncover the Best Heating Method for Your Lab

- What is the range of frequency for induction heating of machine use to melt metals without using fuel? Optimize Your Melting Process

- Can gold be induction heated? Yes, and it's the superior method for high-purity melting.

- What are the safety precautions for induction heating? Mitigate EMF, Shock, and Burn Risks

- How efficient is induction heating? Discover the Power of Direct, Internal Heating