At its core, a graphite furnace is a specialized piece of equipment used for the high-temperature processing of materials, typically within a vacuum or a controlled, protective atmosphere. It is widely employed for advanced applications such as graphitization, sintering, heat treatment, and melting where extreme temperatures and a pure environment are critical.

A graphite furnace is the go-to solution when you need to achieve very high temperatures (often exceeding 2000°C) with excellent uniformity, all while protecting the material from oxygen and other atmospheric contaminants.

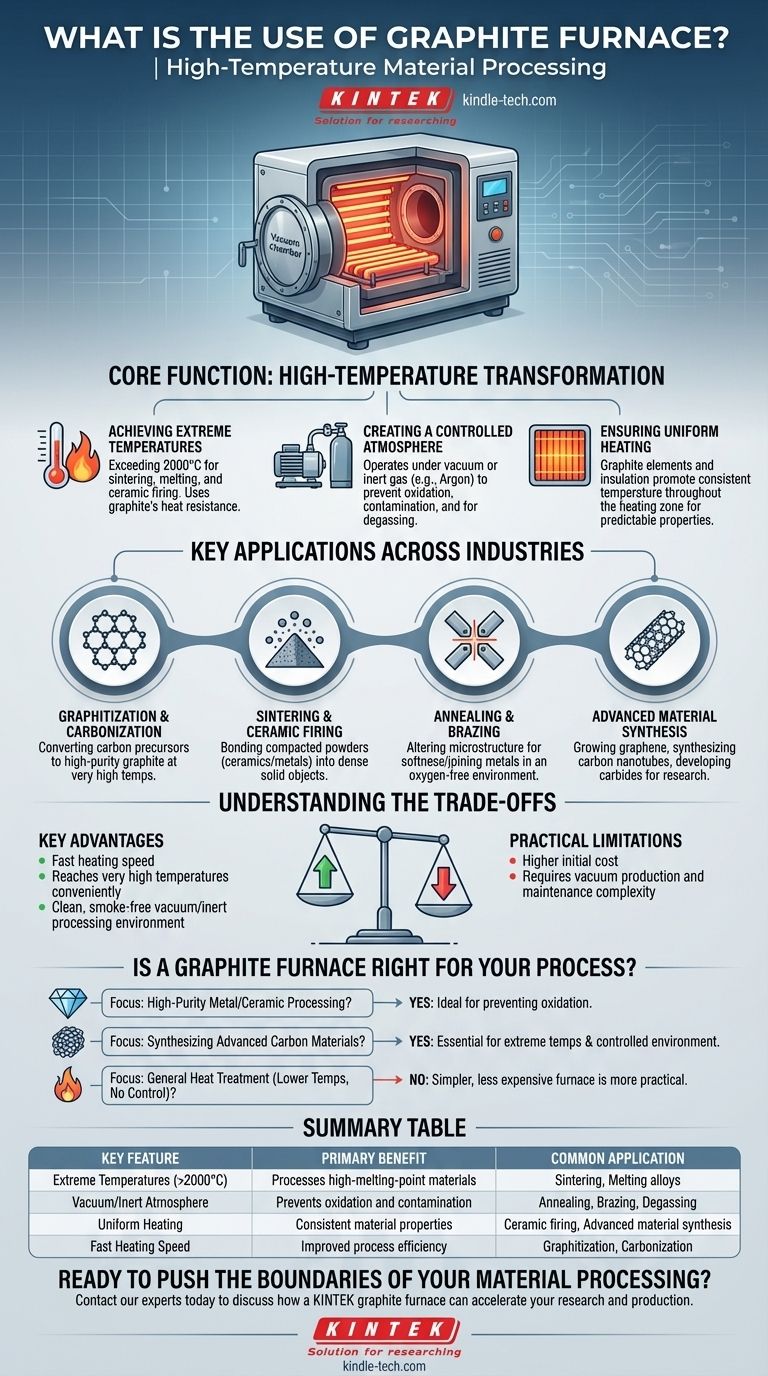

The Core Function: High-Temperature Transformation

A graphite furnace's design leverages the unique properties of graphite, which can withstand extreme heat and has excellent electrical resistance, making it an ideal heating element.

Achieving Extreme Temperatures

Graphite's high melting point and stability allow these furnaces to operate at temperatures far beyond the limits of conventional metallic heating elements.

This capability is essential for processes like sintering (fusing powdered materials together), melting high-temperature alloys, and ceramic firing.

Creating a Controlled Atmosphere

Most graphite furnaces operate under a vacuum or are backfilled with an inert gas like argon.

This controlled environment is crucial for preventing the oxidation or contamination of sensitive materials at high temperatures. It is also used for processes like degassing, which removes trapped gases from a material.

Ensuring Uniform Heating

The design of the graphite heating elements and insulation promotes exceptional temperature uniformity throughout the heating zone.

This consistency ensures that the entire workpiece is processed evenly, which is vital for achieving predictable and reliable material properties after treatment.

Key Applications Across Industries

Graphite furnaces are not general-purpose ovens; they are specialized tools for demanding thermal processes.

Graphitization and Carbonization

This is a primary application where carbon-containing precursor materials are converted into high-purity, crystalline graphite at very high temperatures.

Sintering and Ceramic Firing

The furnace is used to heat compacted powders (like ceramics or metals) to just below their melting point, causing the particles to bond together and form a solid, dense object.

Annealing and Brazing

Annealing involves heating a material to alter its microstructure, typically to make it softer and less brittle. Brazing uses the furnace to melt a filler metal to join two other pieces of metal together, all within a clean, oxygen-free environment.

Advanced Material Synthesis

These furnaces are indispensable in research and production for creating next-generation materials. This includes growing graphene, synthesizing carbon nanotubes, and developing new types of carbides.

Understanding the Trade-offs

While powerful, a graphite furnace is a specialized investment with clear benefits and limitations.

Key Advantages

The primary benefits are its fast heating speed and ability to conveniently reach very high temperatures.

The vacuum or inert atmosphere provides a clean, smoke-free processing environment that prevents unwanted chemical reactions.

Practical Limitations

Graphite furnaces have a higher initial cost compared to standard atmosphere furnaces.

Operating them requires the added complexity of producing and maintaining a vacuum. The large, vacuum-tight joints and seals add to the operational and maintenance overhead.

Is a Graphite Furnace Right for Your Process?

Choosing a furnace depends entirely on your material, temperature requirements, and atmospheric needs.

- If your primary focus is high-purity metal or ceramic processing: The vacuum capability makes it ideal for preventing oxidation during sintering, annealing, or melting.

- If your primary focus is synthesizing advanced carbon materials: A graphite furnace is essential for the extreme temperatures and controlled environments required for graphitization, graphene growth, or nanotube production.

- If your primary focus is general heat treatment at lower temperatures without atmospheric control: A simpler, less expensive furnace is a more practical and cost-effective choice.

Ultimately, a graphite furnace is the definitive tool for pushing the boundaries of material science at extreme temperatures.

Summary Table:

| Key Feature | Primary Benefit | Common Application |

|---|---|---|

| Extreme Temperatures (>2000°C) | Processes high-melting-point materials | Sintering, Melting alloys |

| Vacuum/Inert Atmosphere | Prevents oxidation and contamination | Annealing, Brazing, Degassing |

| Uniform Heating | Consistent material properties | Ceramic firing, Advanced material synthesis |

| Fast Heating Speed | Improved process efficiency | Graphitization, Carbonization |

Ready to push the boundaries of your material processing? A graphite furnace from KINTEK delivers the extreme temperatures and pristine environments required for sintering, graphitization, and advanced material synthesis. Our lab equipment is engineered for precision and reliability, ensuring your most demanding thermal processes are a success. Contact our experts today to discuss how a KINTEK graphite furnace can accelerate your research and production.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the applications of graphite material? Leveraging Extreme Heat and Precision for Industrial Processes

- What temperature can graphite withstand? Unlocking Its Extreme Heat Potential

- What is the purpose of a graphite furnace? Achieve Extreme Temperatures for Advanced Materials

- Can graphite withstand heat? Unlocking its extreme 3,600°C potential in inert environments

- What is the temperature range of a graphite furnace? Unlock up to 3000°C for advanced materials processing.