In short, the primary advantages of a graphite furnace are its rapid heating speed, excellent temperature uniformity, and ability to achieve very high temperatures. These characteristics are delivered within a highly controlled, clean atmosphere, making it ideal for processing sensitive materials.

While its raw performance is impressive, the true value of a graphite furnace lies in its ability to provide precise and repeatable thermal processing for advanced applications where temperature accuracy and atmospheric purity are non-negotiable.

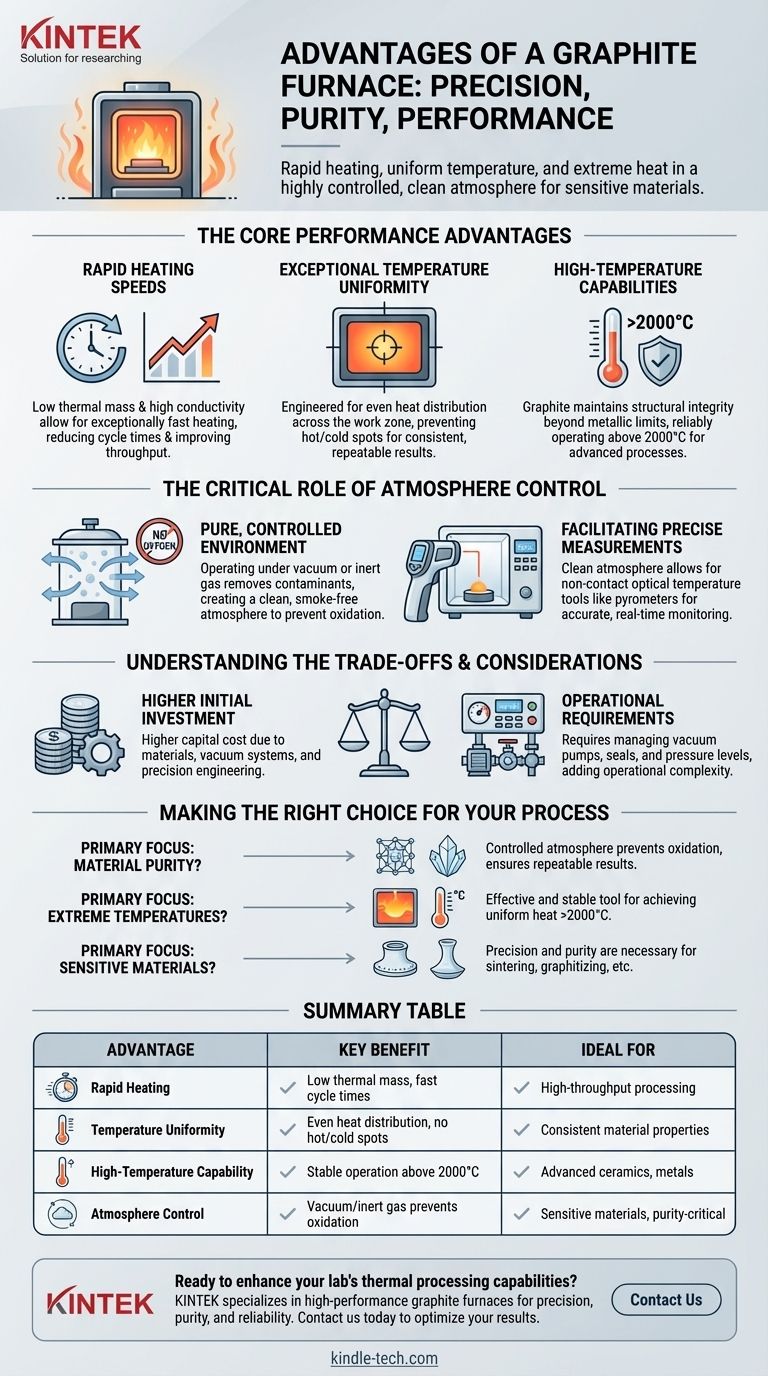

The Core Performance Advantages Explained

A graphite furnace's design is centered around using graphite as the heating element. This material choice directly leads to its key performance benefits.

Rapid Heating Speeds

Graphite elements have low thermal mass and excellent electrical conductivity, allowing them to heat up exceptionally fast. This significantly reduces cycle times compared to other furnace types.

This rapid thermal response not only improves throughput but also provides precise control over the heating profile.

Exceptional Temperature Uniformity

These furnaces are engineered to distribute heat evenly throughout the entire work zone. The design ensures that there are no significant "hot spots" or "cold spots."

This temperature uniformity is critical for ensuring consistent material properties, preventing warping, and achieving repeatable results batch after batch.

High-Temperature Capabilities

Graphite maintains its structural integrity at extreme temperatures, far beyond the limits of most metallic heating elements.

This allows graphite furnaces to operate conveniently and reliably at temperatures often exceeding 2000°C, a requirement for many advanced materials processes.

The Critical Role of Atmosphere Control

Beyond pure heat, the furnace's environment is what sets it apart for high-fidelity work. Most graphite furnaces operate in a vacuum or are backfilled with an inert gas.

Creating a Pure, Controlled Environment

Operating under a vacuum or with inert gas removes oxygen and other potential contaminants. This creates a clean, smoke-free atmosphere.

This prevents oxidation and unwanted chemical reactions, which is essential when working with reactive metals, advanced ceramics, and high-purity carbon materials.

Facilitating Precise Measurements

The clean, particle-free atmosphere inside the furnace allows for the use of non-contact optical temperature measurement tools, such as pyrometers.

This enables highly accurate, real-time temperature monitoring of the material itself without the risk of contaminating the process.

Understanding the Trade-offs and Considerations

While powerful, graphite furnaces are a specialized tool with specific operational considerations.

Higher Initial Investment

The materials, vacuum systems, and precision engineering required for a graphite furnace result in a higher initial capital cost compared to simpler air-atmosphere or metallic-element furnaces.

Operational Requirements

Operating these furnaces involves more than just setting a temperature. Processes often require pulling a vacuum, which involves managing pumps, seals, and pressure levels.

The need to open and close large, vacuum-tight doors and seals adds a layer of operational complexity and maintenance that must be factored in.

Making the Right Choice for Your Process

Choosing a graphite furnace depends on balancing its superior performance against its operational requirements. Your decision should be guided by the primary goal of your thermal process.

- If your primary focus is material purity and quality: The controlled vacuum or inert atmosphere is a critical advantage for preventing oxidation and ensuring repeatable results.

- If your primary focus is reaching extreme temperatures (above 2000°C): A graphite furnace is one of the most effective and stable tools for achieving uniform heat at these levels.

- If your primary focus is processing sensitive materials: For applications like sintering, graphitizing, brazing, or annealing advanced materials, the precision and purity of a graphite furnace are often necessary.

Ultimately, a graphite furnace is a specialized instrument that delivers unparalleled control for the most demanding thermal applications.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Rapid Heating | Low thermal mass, fast cycle times | High-throughput processing |

| Temperature Uniformity | Even heat distribution, no hot/cold spots | Consistent material properties |

| High-Temperature Capability | Stable operation above 2000°C | Advanced ceramics, metals |

| Atmosphere Control | Vacuum/inert gas prevents oxidation | Sensitive materials, purity-critical applications |

Ready to enhance your lab's thermal processing capabilities?

At KINTEK, we specialize in high-performance graphite furnaces designed for precision, purity, and reliability. Whether you're sintering advanced ceramics, annealing reactive metals, or conducting high-temperature research, our furnaces deliver the controlled environment and uniform heating your work demands.

Contact us today to discuss your specific application needs and discover how KINTEK's lab equipment can optimize your results.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What is the temperature of a graphite furnace? Achieve Extreme Heat Up to 3000°C

- Can graphite withstand heat? Unlocking its extreme 3,600°C potential in inert environments

- Why is graphite used in furnaces? For Extreme Heat, Purity, and Efficiency

- Does graphite have a melting point? Unlocking the Extreme Heat Resistance of Graphite

- What are the advantages of graphite? Unlock Superior Performance in High-Temperature Processes