At its core, a mechanical press is a machine that uses a motor-driven flywheel to store energy, which is then rapidly transferred to a ram or slide to cut, form, punch, or shape material. Its primary function is to perform high-speed, repeatable metalworking operations with immense force, making it a cornerstone of mass production.

The defining characteristic of a mechanical press is not just its power, but its speed and consistency. It excels at high-volume production where the same operation is repeated thousands or millions of times with exacting precision.

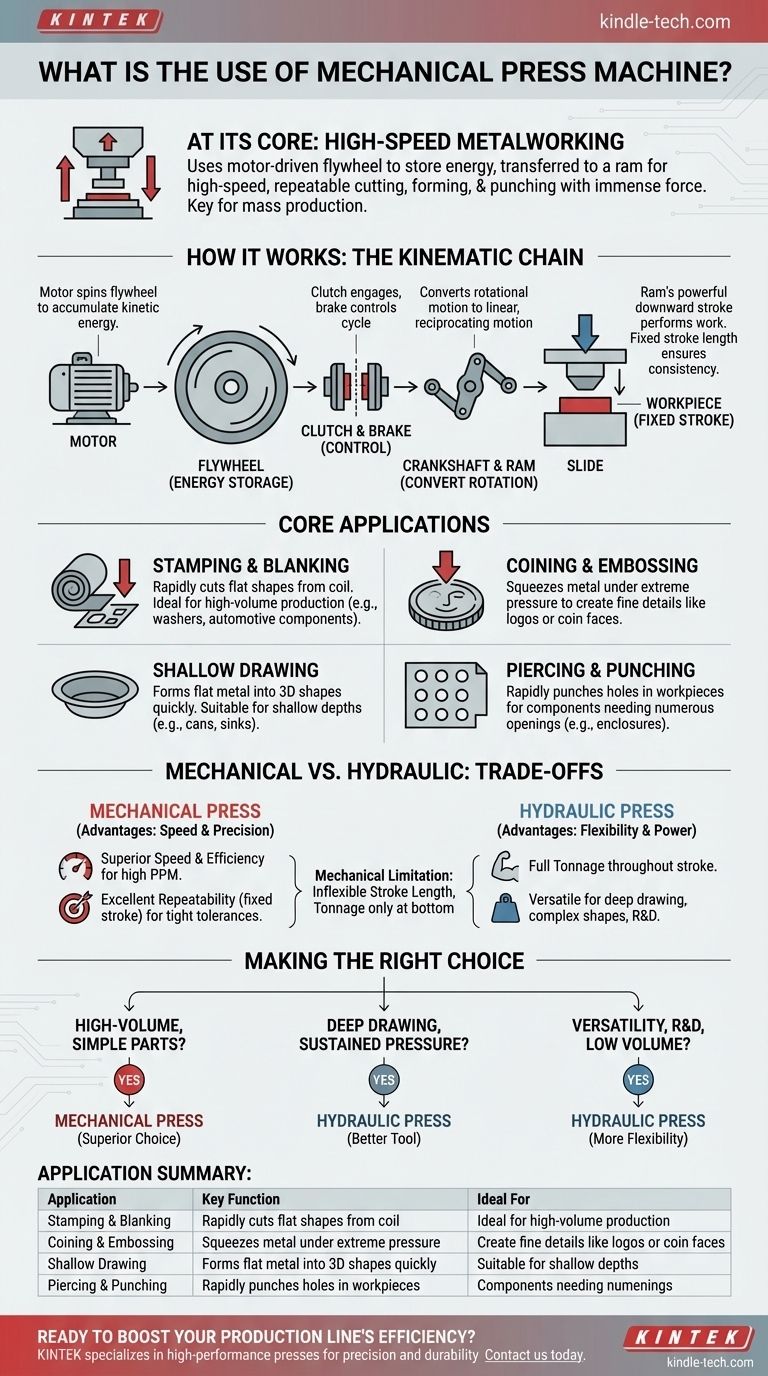

How a Mechanical Press Works: The Kinematic Chain

To understand the use of a mechanical press, you must first understand its operating principle. It's a system designed to convert rotational energy from a motor into a powerful, linear stamping motion.

The Motor and Flywheel: Storing Kinetic Energy

The process begins with an electric motor that spins a large, heavy flywheel. The flywheel acts like a mechanical battery, accumulating and storing a massive amount of kinetic energy.

This continuous energy storage is what allows the press to deliver a powerful blow without requiring an impossibly large motor.

The Clutch and Brake: Controlling the Power

When the operator initiates a cycle, a clutch engages. This instantly connects the spinning flywheel to the press's drivetrain.

A corresponding brake system disengages the drivetrain at the top of the stroke, ensuring safety and precise control over when the press cycles.

The Crankshaft and Ram: Converting Rotation to Linear Force

The energy from the flywheel is transferred to a crankshaft or an eccentric gear system. Much like the engine in a car, this mechanism converts the rotational motion into a reciprocating (up-and-down) linear motion.

This linear motion drives the ram (also called a slide), a massive component to which the upper die is attached. It is the ram's powerful downward stroke that performs the work on the material.

The Defining Stroke: Pre-set and Repeatable

A key feature of a mechanical press is its fixed stroke length. The distance the ram travels from top to bottom is determined by the mechanical design of the crankshaft.

This fixed stroke ensures that every single cycle is identical to the last, providing exceptional repeatability and consistency, which is critical for producing uniform parts.

Core Applications: Where Mechanical Presses Excel

The speed and precision of a mechanical press make it the ideal choice for specific, high-volume manufacturing tasks.

High-Speed Stamping and Blanking

This is the most common application. A mechanical press can rapidly "blank" or cut flat shapes from a continuous coil of sheet metal. Think of it as a highly precise, industrial-strength cookie cutter used for making everything from washers to automotive frame components.

Coining and Embossing

These processes involve squeezing metal under extreme pressure to create fine details, such as the face on a coin or a logo on a metal part. The mechanical press's ability to deliver a sharp, high-tonnage blow at the bottom of its stroke is perfect for this.

Shallow Drawing

Drawing is the process of forming flat metal into a three-dimensional shape, like a can or a kitchen sink. Mechanical presses are excellent for "shallow" draws where the depth is not extreme, as they can perform the operation quickly.

Piercing and Punching

Similar to blanking, these operations involve punching holes in a workpiece. Mechanical presses can perform hundreds of piercing strokes per minute, making them essential for creating parts like electrical enclosures or chassis components that require numerous holes.

Understanding the Trade-offs: Mechanical vs. Hydraulic

No machine is perfect for every job. The choice to use a mechanical press often comes down to its advantages over its main alternative, the hydraulic press.

Advantage: Speed and Efficiency

For repetitive tasks, nothing beats the speed of a mechanical press. The flywheel-based system is exceptionally efficient at delivering rapid, successive strokes, leading to much higher parts-per-minute output than a hydraulic press.

Advantage: Precision and Repeatability

Because the stroke length is mechanically fixed, a mechanical press offers superior dimensional consistency from part to part. This is crucial for industries with tight tolerances, such as electronics and automotive manufacturing.

Limitation: Inflexible Stroke Length

The fixed stroke is also a limitation. You cannot easily change the stroke length or have the ram dwell at the bottom of the stroke. Operations that require variable pressure or a long pressing time are not a good fit.

Limitation: Tonnage at the Bottom

A mechanical press only delivers its maximum rated tonnage at the very bottom of its stroke. If your operation requires full force applied over a longer distance (like in deep drawing), a hydraulic press—which provides full tonnage throughout its stroke—is a better choice.

Making the Right Choice for Your Operation

Ultimately, selecting the right machine depends entirely on the requirements of the job.

- If your primary focus is high-volume production of simple stamped or shallow-formed parts: A mechanical press is almost always the superior choice due to its speed and efficiency.

- If your primary focus is deep drawing or forming complex shapes that require sustained pressure: A hydraulic press is the better tool because it provides full tonnage throughout the entire stroke.

- If your primary focus is versatility and control over stroke length and pressure: A hydraulic press offers far more flexibility for R&D, prototyping, or low-volume, high-variation work.

Matching the fundamental characteristics of the machine to the demands of your application is the key to efficient and successful manufacturing.

Summary Table:

| Application | Key Function | Ideal For |

|---|---|---|

| Stamping & Blanking | Cutting flat shapes from sheet metal | High-volume production of components (e.g., washers, automotive parts) |

| Coining & Embossing | Creating fine details under extreme pressure | Precision work like logos or coin faces |

| Shallow Drawing | Forming 3D shapes from flat metal | Quick, shallow draws (e.g., cans, sinks) |

| Piercing & Punching | Creating holes in workpieces | Rapid, repetitive hole-making (e.g., electrical enclosures) |

Ready to boost your production line's efficiency? KINTEK specializes in high-performance lab equipment and industrial machinery, including mechanical presses designed for precision and durability. Whether you're in automotive, electronics, or general manufacturing, our solutions ensure consistent, high-volume output. Contact us today to find the perfect press for your metalworking needs!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Double Plate Heating Press Mold for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is similar to a hydraulic press? Force Multipliers for Your Lab & Workshop

- What is the principle of forging press? Achieve Superior Strength with Controlled Metal Deformation

- What are the risks of a hydraulic press? Essential Safety and Operational Insights

- What is the difference between a servo press and a pneumatic press? Match the Right Technology to Your Manufacturing Goal

- Why use 500 MPa pressure for BZCY72 electrolytes? Achieve 95% Theoretical Density with High-Pressure Hydraulic Presses

- How do you specify an injection molding machine? A Step-by-Step Guide to Choosing the Right Tonnage, Shot Size, and Drive System

- What is the principle of mechanical forging press? Harnessing Kinetic Energy for High-Volume Forging

- What role does a high-precision laboratory hydraulic press play in ICDP membranes? Optimize Ceramic Support Formation