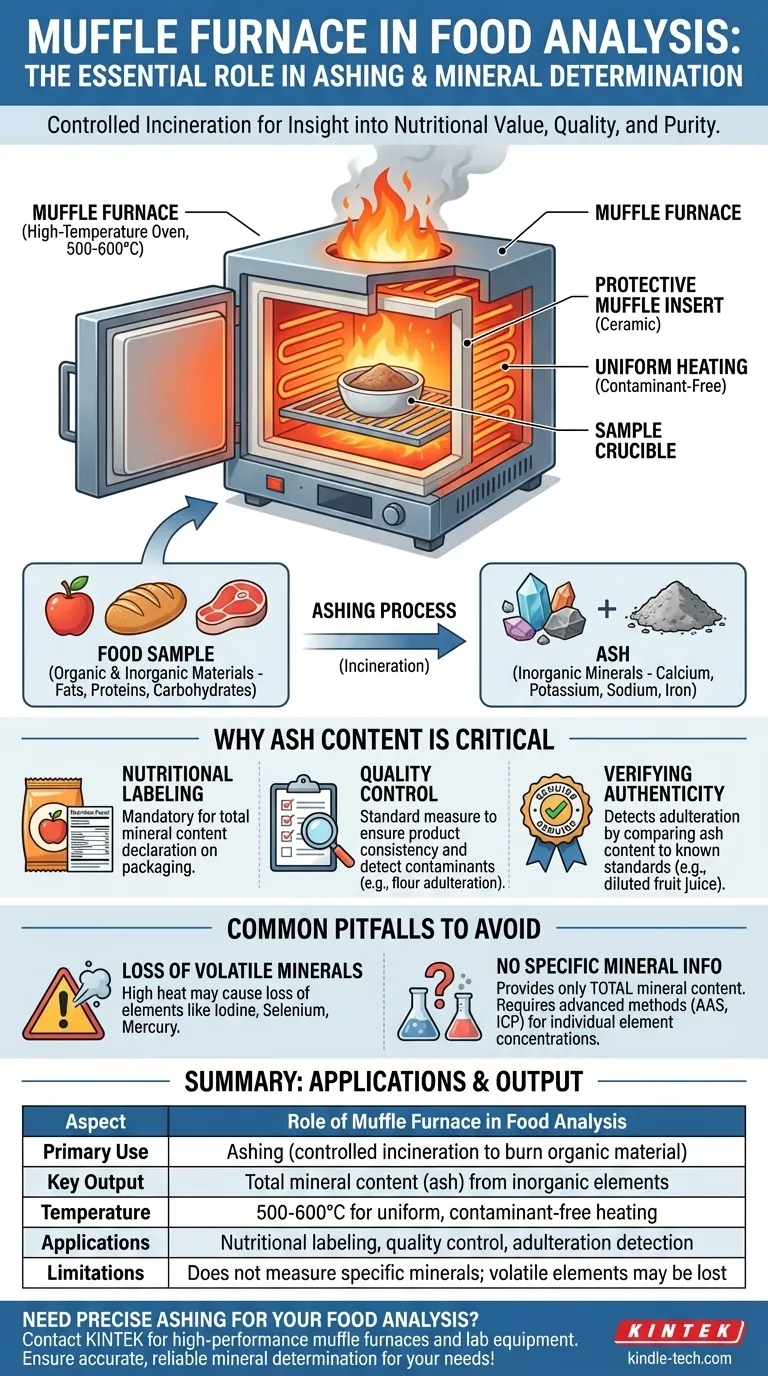

In food analysis, a muffle furnace is primarily used for "ashing." This is the process of controlled incineration that burns away all organic material—such as fats, proteins, and carbohydrates—from a food sample, leaving behind only the inorganic minerals which constitute the ash.

The core purpose of using a muffle furnace is to determine the total mineral content of a food product. This measurement is a fundamental indicator of a food's nutritional value, quality, and purity.

The Core Principle: Incineration for Insight

To understand its role, it's essential to look at how a muffle furnace operates and what the resulting "ash" truly represents.

How a Muffle Furnace Works

A muffle furnace is a specialized high-temperature oven, often reaching 500-600°C for food analysis.

Its key feature is the "muffle"—a protective insert, typically made of high-temperature ceramic. This muffle separates the sample from the direct heat source (the heating elements).

This design ensures the sample is heated uniformly and is protected from any potential contaminants from the heating elements, guaranteeing a clean and complete combustion process.

What "Ash" Really Is

The term "ash" can be misleading. It is not simply burnt residue.

In the context of food analysis, ash is the collection of inorganic minerals like calcium, potassium, sodium, and iron that do not combust at high temperatures. The furnace effectively removes everything else, isolating this mineral content for measurement.

Why Ash Content is Critical in Food Analysis

Measuring the total mineral content is not just an academic exercise; it provides critical data for safety, nutrition, and quality control.

Nutritional Labeling and Compliance

The ash value represents the total mineral content in a food. This is a mandatory component of proximate analysis, which forms the basis for the nutritional information panel on food packaging.

A Key Indicator of Quality Control

For many food products, the ash content is a standard measure of quality.

For example, a higher-than-normal ash content in flour could indicate contamination with bran or sand. In fruit juices, it can help determine the fruit content versus added sugars.

Verifying Food Authenticity

Ash analysis can be used to detect adulteration. An unusually high or low ash content compared to a known standard can signal that a product has been diluted or contaminated with cheaper ingredients.

Common Pitfalls to Avoid

While powerful, the ashing process has limitations that are important to understand for accurate interpretation.

Loss of Volatile Minerals

The extremely high temperatures can cause certain volatile minerals, such as iodine, selenium, and mercury, to be lost during the process. This means the final ash weight may not include these specific elements.

No Information on Specific Minerals

The muffle furnace provides the total mineral content only. It cannot tell you the specific amounts of calcium, iron, or potassium.

Determining the concentration of individual minerals requires subsequent analytical techniques, such as Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma (ICP) analysis.

Making the Right Choice for Your Goal

The use of a muffle furnace is foundational, but its data should be applied correctly based on your objective.

- If your primary focus is nutritional labeling: Muffle furnace ashing is the standard industry method for determining the total mineral content required for nutrition facts.

- If your primary focus is quality control: It is a highly effective and reliable method for checking product consistency against an established quality standard.

- If your primary focus is specific mineral analysis: View the ashing process as the essential first step to prepare a clean, organic-free sample for more advanced analytical methods.

Ultimately, this high-temperature process provides a fundamental piece of data that underpins our understanding of a food's composition and value.

Summary Table:

| Aspect | Role of Muffle Furnace in Food Analysis |

|---|---|

| Primary Use | Ashing (controlled incineration to burn organic material) |

| Key Output | Total mineral content (ash) from inorganic elements like calcium, potassium |

| Temperature Range | 500-600°C for uniform, contaminant-free heating |

| Applications | Nutritional labeling, quality control, adulteration detection |

| Limitations | Does not measure specific minerals; volatile elements may be lost |

Need precise ashing for your food analysis? KINTEK specializes in high-performance muffle furnaces and lab equipment designed for accurate, contaminant-free mineral determination. Whether you're focused on nutritional labeling, quality assurance, or sample preparation for advanced analysis, our solutions ensure reliable results. Contact our experts today to find the perfect furnace for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the application of a muffle furnace? Achieve Contamination-Free High-Temperature Processing

- How do you use the muffle furnace? Master Safe and Precise High-Temperature Processing

- What is melt loss? The Ultimate Guide to Reducing Metal Loss in High-Temp Processing

- What precautions you will take while handling the muffle furnace? Ensure Safe and Efficient Operation

- How does heat treatment affect surface roughness? Minimize Surface Degradation for Precision Parts