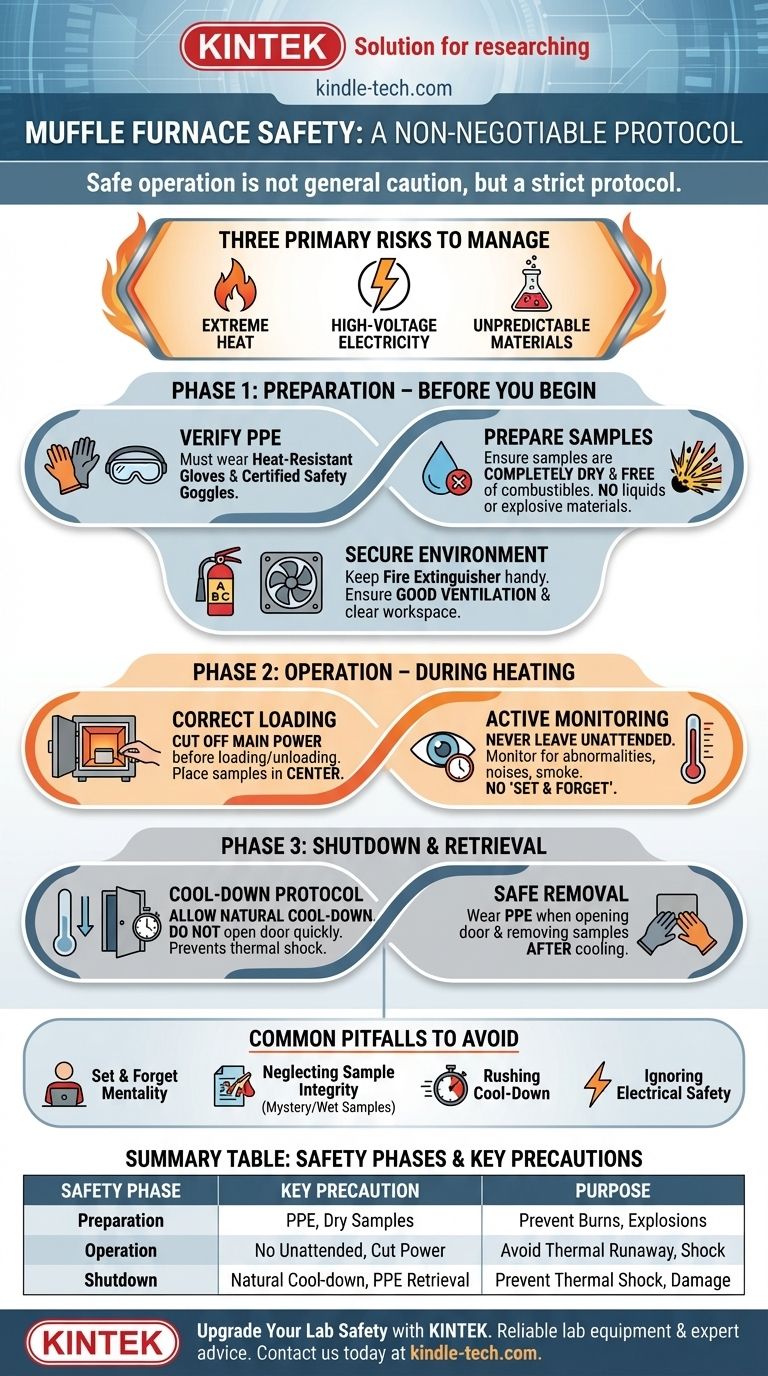

Safe operation of a muffle furnace is not a matter of general caution but a strict, non-negotiable protocol. The most critical precautions are always wearing appropriate Personal Protective Equipment (PPE), meticulously preparing your samples to remove all moisture and combustibles, and actively monitoring the furnace throughout its entire heating and cooling cycle. Never assume the process is automated or fail-safe.

True muffle furnace safety is about systematically managing three primary risks at all times: the extreme heat produced, the high-voltage electrical components, and the unpredictable chemical nature of the materials being heated. Every safety step is a deliberate control measure for one of these fundamental hazards.

Phase 1: Preparation – Before You Begin

Proper preparation accounts for the majority of muffle furnace safety. Rushing this stage introduces unnecessary and severe risks before the equipment is even turned on.

Verify Your Personal Protective Equipment (PPE)

Your first line of defense is what you wear. Standard lab coats are not sufficient.

You must wear heat-resistant gloves rated for the temperatures you will be working with and certified safety goggles to protect against heat radiation and potential spattering.

Prepare Your Samples Correctly

The most catastrophic furnace failures often originate with the sample itself. You must know exactly what you are putting inside.

Ensure all samples are completely dry and free from water, oils, or other liquids. Trapped liquids can vaporize explosively, damaging the furnace and creating a projectile hazard.

Critically, confirm that no combustible or explosive materials are present in your samples. Know the melting and ignition points of every substance being heated.

Secure the Operating Environment

The furnace does not exist in isolation. The area around it must be prepared for safe operation.

Keep a Class ABC or Class D fire extinguisher within easy reach. Ensure the furnace is positioned away from any flammable materials, as the outer jacket will become extremely hot. Good ventilation is also critical to dissipate heat and potential off-gassing from samples.

Phase 2: Operation – During the Heating Cycle

Once the furnace is running, your role shifts from preparation to active supervision.

The Correct Loading and Programming Procedure

To prevent electric shock, always cut off the main power supply before loading or unloading samples. This is a critical step that is often overlooked.

Place samples in the center of the furnace chamber to ensure even heating and prevent contact with the heating elements. When you close the door, ensure the opening time is as short as possible to maintain thermal stability.

Finally, program the furnace according to the manufacturer's instructions. Never exceed the maximum rated temperature of the unit.

Active Monitoring is Non-Negotiable

A muffle furnace should never be left unattended while in operation, especially overnight. Electronic controls can fail, leading to thermal runaway and a significant fire hazard.

Listen and look for any abnormalities, such as unusual noises, smoke, or erratic temperature readings. If you notice anything wrong, perform an emergency shutdown immediately and contact maintenance personnel.

Phase 3: Shutdown and Retrieval

The process is not over when the heating cycle completes. The cooling phase presents its own set of hazards.

The Cool-Down Protocol

After the heating program is finished, turn off the power supply. Do not open the furnace door immediately.

Allow the furnace to cool down naturally over several hours. Attempting to speed up this process by opening the door can cause thermal shock, cracking the furnace's internal insulation and potentially shattering your samples.

Safe Sample Removal

Even after hours of cooling, the furnace and its contents will be extremely hot. Always wear your heat-resistant gloves and safety goggles when opening the door and removing your samples.

Common Pitfalls to Avoid

Mistakes with muffle furnaces are rarely minor. Understanding these common errors is key to preventing them.

The "Set and Forget" Mentality

The most dangerous assumption is that the furnace can run without supervision. Control circuit failures are a known risk, and the only reliable failsafe is an alert operator ready to intervene.

Neglecting Sample Integrity

Putting a "mystery sample" or a wet sample into a furnace is a gamble. The risk of a small-scale explosion, release of toxic fumes, or damage to the heating elements is unacceptably high.

Rushing the Cool-Down

Impatience is the enemy of both safety and equipment longevity. Opening the door on a hot furnace creates immense thermal stress on the refractory materials, leading to cracks and costly repairs. It can also cause samples to shatter.

Ignoring Electrical Safety

The heating elements in a muffle furnace operate at high voltage. Reaching into a powered furnace, even if it is not actively heating, exposes you to a lethal risk of electric shock. Always de-energize the unit before the door is opened.

Making the Right Choice for Your Goal

Your specific task will determine which safety protocols require the most focus.

- If your primary focus is personal safety: Always prioritize wearing appropriate, heat-rated PPE and de-energizing the furnace before loading or unloading samples.

- If your primary focus is preventing fires or explosions: Meticulously inspect every sample to ensure it is dry and free of unrated materials, and maintain a clear, uncluttered workspace.

- If your primary focus is equipment longevity and reliable results: Adhere strictly to the manufacturer's specified heating rates, maximum temperatures, and natural cool-down procedures.

By treating the muffle furnace with systematic diligence at every stage, you ensure safety, protect your equipment, and guarantee the integrity of your work.

Summary Table:

| Safety Phase | Key Precaution | Purpose |

|---|---|---|

| Preparation | Wear heat-resistant gloves and safety goggles; ensure samples are dry and non-combustible. | Prevent burns, explosions, and sample-related hazards. |

| Operation | Never leave unattended; cut power before loading/unloading; monitor for abnormalities. | Avoid thermal runaway, electric shock, and fire risks. |

| Shutdown | Allow natural cool-down; use PPE to retrieve samples after cooling. | Prevent thermal shock, equipment damage, and injuries. |

Upgrade Your Lab Safety with KINTEK

Handling a muffle furnace requires precision and the right equipment to mitigate risks. At KINTEK, we specialize in providing reliable lab equipment and consumables designed with safety and efficiency in mind. Whether you need a durable muffle furnace, compatible accessories, or expert advice on safe operation protocols, we are here to support your laboratory needs.

Ensure your lab operates safely and effectively — contact us today to explore our products and solutions tailored for your specific requirements!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the working temperature of a muffle furnace? Achieve Precise Heat Control for Your Lab

- What is the temperature limit on a muffle furnace? A Guide to Selecting the Right Model

- What is the power requirement for a muffle furnace? Ensure Safe and Efficient Operation

- What is the burnout cycle on a furnace? Stop This Destructive Overheating Pattern Now

- What is the temperature range of a furnace? From 1100°C to Over 2000°C Explained