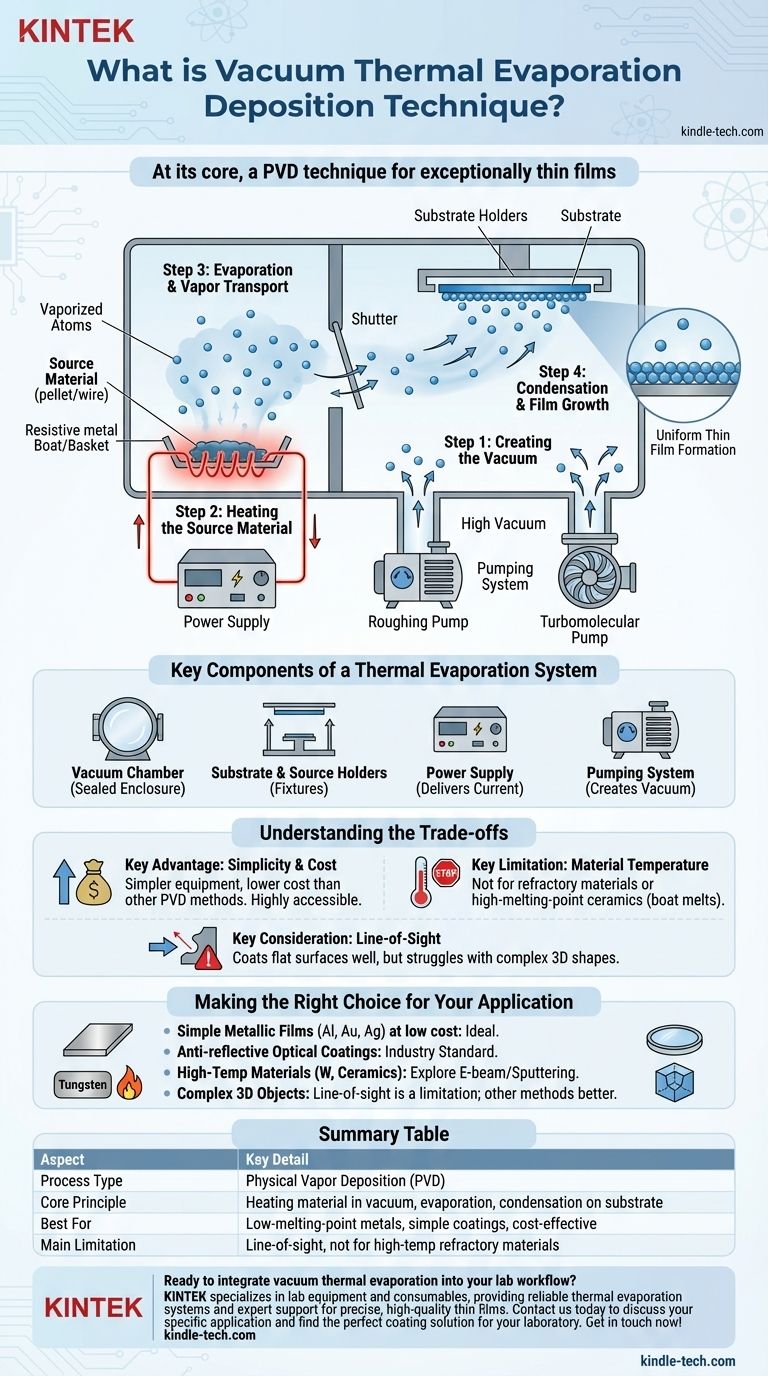

At its core, vacuum thermal evaporation is a physical vapor deposition (PVD) technique used to create exceptionally thin films on a surface. The process involves heating a source material inside a high-vacuum chamber until it evaporates. This vapor then travels through the vacuum and condenses onto a cooler target object, known as a substrate, forming a uniform thin film.

The fundamental principle is straightforward: heat transforms a solid material into a vapor, and a high vacuum allows this vapor to travel unimpeded to a cooler surface, where it condenses back into a pure, solid film.

The Step-by-Step Evaporation Process

To understand thermal evaporation, it's best to break it down into the distinct stages that occur within the deposition system.

Step 1: Creating the Vacuum

The substrate to be coated and the source material (often in pellet or wire form) are placed inside a sealed vacuum chamber. A powerful pumping system, typically combining a roughing pump and a high-vacuum pump like a turbomolecular pump, removes air and other gases.

This vacuum is critical because it minimizes the chances of evaporated atoms colliding with air molecules on their way to the substrate, ensuring a pure and direct path.

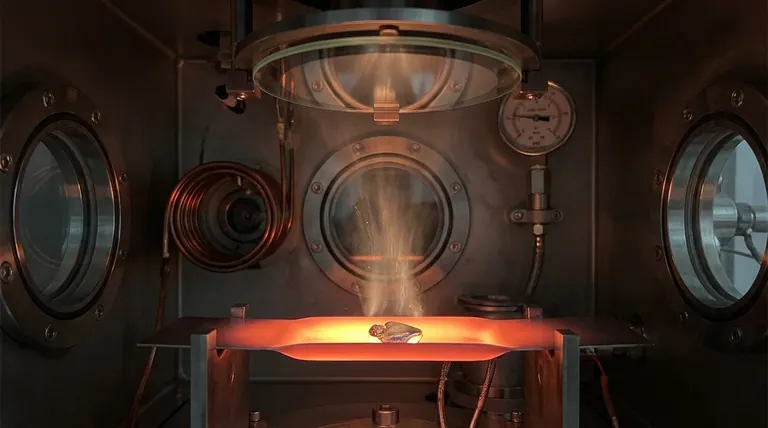

Step 2: Heating the Source Material

The source material is placed in a container, often called a "boat" or "basket," made from a resistive metal. A high electrical current is passed through this boat.

Due to its electrical resistance, the boat heats up rapidly, transferring this thermal energy to the source material. This method is why the technique is also known as resistive evaporation.

Step 3: Evaporation and Vapor Transport

As the source material's temperature rises to its evaporation point, its atoms gain enough energy to transform into a gaseous vapor.

These vaporized atoms travel in a straight line away from the source. A shutter is often used to block the substrate initially, ensuring the evaporation rate is stable before the coating begins.

Step 4: Condensation and Film Growth

The gaseous atoms eventually reach the cooler substrate, where they lose their energy and condense back into a solid state.

This condensation builds up layer by layer, forming a thin, solid film on the substrate's surface. The thickness of this film is precisely controlled by monitoring the deposition rate in real-time.

Key Components of a Thermal Evaporation System

A typical thermal evaporation system relies on a few core components working in unison.

The Vacuum Chamber

This is the sealed enclosure that houses the entire process. It's designed to withstand the pressure difference between the high vacuum inside and the atmosphere outside.

Substrate and Source Holders

Fixtures at the top of the chamber hold the substrate, often in an inverted position. At the bottom, the evaporation source (the resistive boat or coil) holds the material that will be evaporated.

The Power Supply

A dedicated power supply delivers the high electrical current necessary to heat the resistive boat to the required temperature for evaporation.

The Pumping System

This is a multi-stage system responsible for creating the high-vacuum environment. It typically includes a primary pump (like a rotary vane or scroll pump) and a secondary high-vacuum pump.

Understanding the Trade-offs

Like any technical process, thermal evaporation has distinct advantages and limitations that make it suitable for some applications but not others.

Key Advantage: Simplicity and Cost

The primary benefit of thermal evaporation is its relative simplicity and lower equipment cost compared to more complex PVD methods like sputtering or electron-beam evaporation. This makes it highly accessible for many applications.

Key Limitation: Material Temperature

The process relies on heating a material until it evaporates. This works well for materials with relatively low evaporation points, such as aluminum, gold, or chrome.

However, it is not suitable for refractory materials or ceramics with extremely high melting points, as the resistive boat may melt or be damaged before the source material evaporates.

Key Consideration: Line-of-Sight Deposition

The evaporated atoms travel in a straight line from the source to the substrate. This "line-of-sight" nature means it is excellent for coating flat surfaces but can struggle to uniformly coat complex, three-dimensional shapes with undercuts or hidden surfaces.

Making the Right Choice for Your Application

Selecting a deposition technique depends entirely on your material, substrate, and desired outcome.

- If your primary focus is depositing a simple metallic film (e.g., aluminum, silver, gold) at a low cost: Thermal evaporation is often the most efficient and economical choice.

- If your goal is to create anti-reflective optical coatings or protective layers on lenses: This technique is a well-established industry standard.

- If you must deposit a film of a high-temperature material like tungsten or a ceramic compound: You should explore alternative methods like electron-beam evaporation or magnetron sputtering.

- If you need to uniformly coat a complex 3D object: The line-of-sight nature may be a limitation, and other methods might provide better conformity.

Ultimately, vacuum thermal evaporation is a foundational thin-film technology valued for its simplicity, speed, and effectiveness in a wide range of critical applications.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Heating a material in a vacuum until it evaporates and condenses on a substrate. |

| Best For | Low-melting-point metals (e.g., Al, Au, Ag), simple coatings, cost-effective projects. |

| Main Limitation | Line-of-sight deposition; not suitable for high-temperature refractory materials. |

Ready to integrate vacuum thermal evaporation into your lab workflow?

KINTEK specializes in lab equipment and consumables, providing reliable thermal evaporation systems and expert support to help you achieve precise, high-quality thin films for your research or production needs. Our solutions are designed for efficiency and ease of use, ensuring you get the results you need.

Contact us today to discuss your specific application and find the perfect coating solution for your laboratory. Get in touch now!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Tungsten Evaporation Boat for Thin Film Deposition

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition

- What is the thermal evaporation technique? A Guide to Thin-Film Deposition for Your Lab

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD

- What is the difference between sputtering and thermal evaporation? Choose the Right PVD Method for Your Thin Film

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition