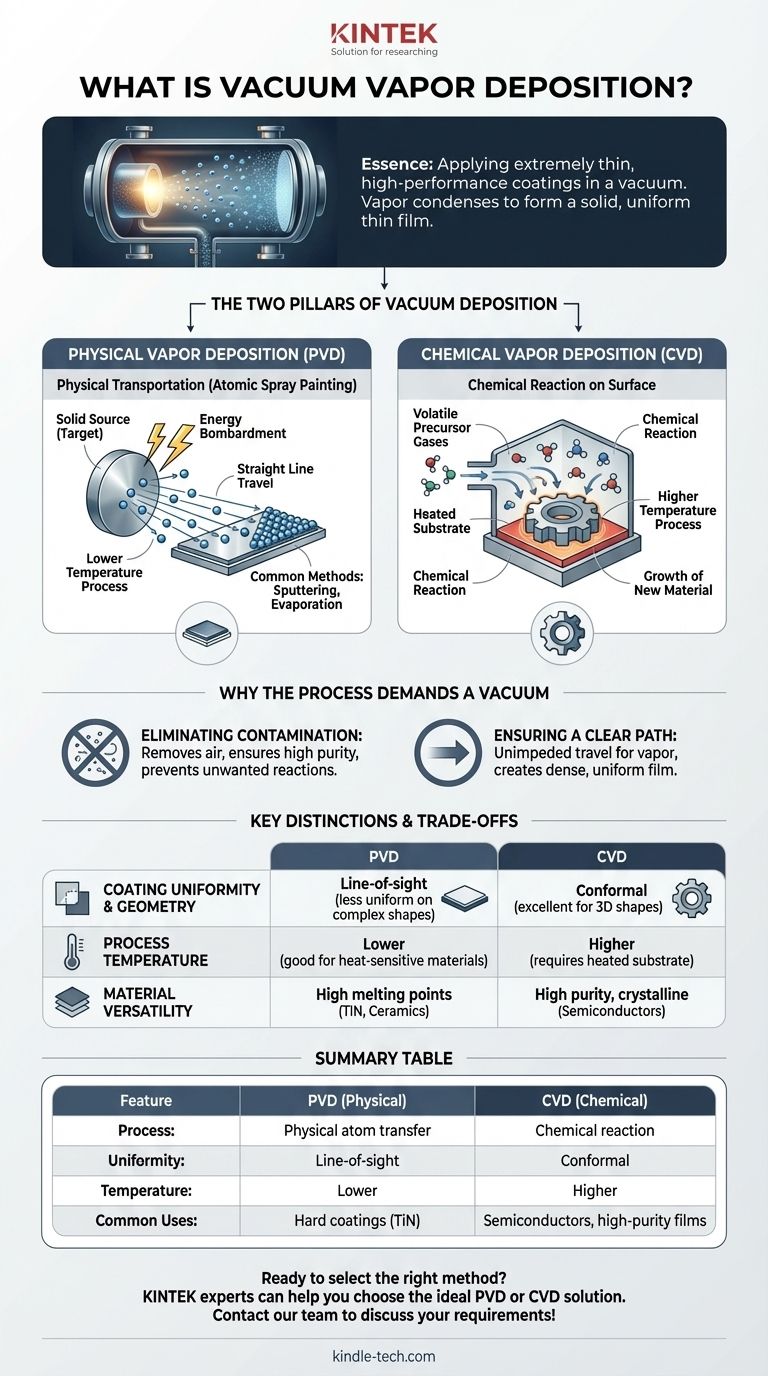

In essence, vacuum vapor deposition is a family of high-tech processes used to apply extremely thin, high-performance coatings to a surface. These processes all take place inside a vacuum chamber, where a coating material is converted into a vapor. This vapor then travels and condenses onto the object being coated, forming a solid, uniform thin film.

The critical distinction to understand is not the vacuum itself, but how the coating is created. The two main methods, Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), achieve the same goal through fundamentally different mechanisms.

The Two Pillars of Vacuum Deposition

At its core, vacuum deposition is divided into two primary categories. The choice between them depends entirely on the desired coating material, the properties of the object being coated (the substrate), and the final application.

Physical Vapor Deposition (PVD)

PVD is a process of physical transportation. Think of it as an atomic-level form of spray painting.

A solid source material, known as the target, is bombarded with energy inside the vacuum. This energy physically dislodges atoms from the target, turning them into a vapor.

This vapor of pure source material then travels in a straight line through the vacuum and condenses on the substrate, building up the thin film atom by atom. Common PVD methods include sputtering and evaporation.

Chemical Vapor Deposition (CVD)

CVD is a process of chemical reaction. Instead of physically moving atoms, it grows a new material directly on the substrate's surface.

In this method, one or more volatile precursor gases are introduced into the vacuum chamber. When these gases come into contact with the heated substrate, a chemical reaction is triggered.

This reaction causes a new, solid material to form and deposit on the substrate. The byproducts of the reaction are then pumped out of the chamber.

Why the Process Demands a Vacuum

The vacuum is not just a container; it is an essential and active part of the deposition process. Without it, these advanced coatings would be impossible to create.

Eliminating Contamination

A vacuum removes air and other unwanted particles from the chamber. This ensures that the coating being deposited is exceptionally pure and doesn't react with stray molecules like oxygen or nitrogen, which would compromise its quality.

Ensuring a Clear Path

In a vacuum, the vaporized coating particles can travel from the source to the substrate without colliding with air molecules. This direct, unimpeded path is crucial for creating a dense, well-adhered, and uniform film.

Key Distinctions and Trade-offs

While both PVD and CVD produce thin films, their different mechanisms lead to important trade-offs in application.

Coating Uniformity and Geometry

CVD gases can flow around complex, three-dimensional shapes, resulting in a highly uniform (conformal) coating even on intricate surfaces.

PVD is largely a "line-of-sight" process. Areas not directly facing the source target will receive little to no coating, making it better suited for flatter surfaces.

Process Temperature

CVD typically requires the substrate to be heated to high temperatures to trigger the necessary chemical reaction. This can limit the types of materials that can be coated without being damaged.

PVD can often be performed at much lower temperatures, making it compatible with a wider range of materials, including plastics and heat-sensitive alloys.

Material Versatility

PVD is exceptionally good at depositing materials with very high melting points, such as titanium, chromium, and various ceramics, which are difficult to vaporize by other means.

CVD excels at creating highly pure, crystalline materials, including those used in the semiconductor industry like silicon nitride and silicon dioxide.

How to Apply This to Your Goal

Your choice between deposition methods is dictated by the specific requirements of your final product.

- If your primary focus is coating a complex 3D shape uniformly: Consider CVD, as the gaseous precursors can conform to intricate surfaces where PVD cannot.

- If your primary focus is applying a hard, wear-resistant coating to tools or components at low temperatures: PVD is the standard industry choice for materials like titanium nitride (TiN).

- If your primary focus is growing a highly pure, specific chemical compound for electronics: CVD is the foundational process for modern semiconductor fabrication.

- If you are replacing traditional electroplating for environmental reasons: Both PVD and CVD are excellent 'dry process' alternatives to wet plating methods like chromium and cadmium.

Ultimately, selecting the correct vacuum deposition technique requires matching the specific properties of the process to the desired performance of the final product.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process | Physical atom transfer | Chemical reaction on substrate |

| Uniformity | Line-of-sight (less uniform on complex shapes) | Conformal (excellent for 3D shapes) |

| Temperature | Lower (good for heat-sensitive materials) | Higher (requires heated substrate) |

| Common Uses | Hard coatings (TiN), wear resistance | Semiconductors, high-purity crystalline films |

Ready to select the right deposition method for your application? KINTEK specializes in lab equipment and consumables for all your vacuum deposition needs. Our experts can help you choose the ideal PVD or CVD solution to enhance your product's performance, durability, and efficiency. Contact our team today to discuss your project requirements!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty