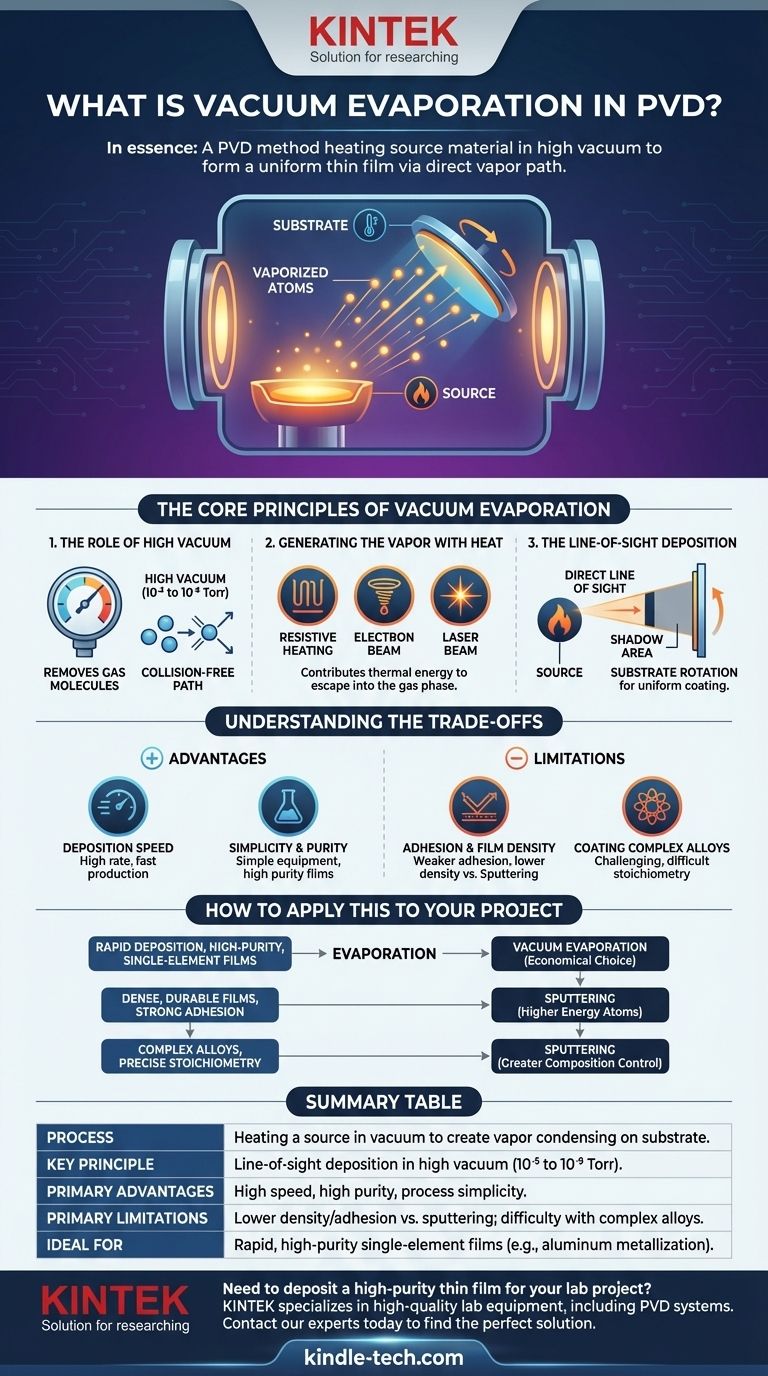

In essence, vacuum evaporation is a method of Physical Vapor Deposition (PVD) where a source material is heated within a high-vacuum chamber until it turns into a vapor. These vaporized atoms travel in a straight line and condense onto a cooler substrate, forming a uniform thin film. The vacuum is critical because it prevents the vaporized atoms from colliding with air molecules, ensuring a pure and direct path to the target surface.

Vacuum evaporation is fundamentally a process of boiling or sublimating a material in a near-perfect vacuum. The resulting vapor travels unimpeded, coating everything in its direct line of sight to create a thin film.

The Core Principles of Vacuum Evaporation

To understand this process, it's best to break it down into its three critical components: the vacuum, the heat source, and the path of the vapor.

The Role of High Vacuum

The entire process occurs inside a chamber where the pressure is reduced to a high vacuum, typically in the range of 10⁻⁵ to 10⁻⁹ Torr.

This extreme vacuum serves two primary purposes. First, it removes unwanted gas molecules, which prevents the source vapor from reacting with air and creating impurities in the final film.

Second, it provides a clear, collision-free path for the vaporized atoms to travel from the source to the substrate, a key principle of the technique.

Generating the Vapor with Heat

To create the vapor, the source material is heated intensely until it either melts and evaporates (boils) or sublimates (turns directly from a solid to a gas).

The heating mechanism can vary significantly depending on the material's properties. Common methods include resistive heating (passing a current through a filament or boat), using a high-energy electron beam, or even a focused laser beam.

The goal is simply to give the source atoms enough thermal energy to escape into the gas phase.

The Line-of-Sight Deposition

Once vaporized, the atoms travel away from the source in straight lines. This is known as "line-of-sight" deposition.

This means the material will only coat surfaces that have an unobstructed view of the source. Any object in the path will create a "shadow" behind it where no deposition occurs.

Because of this, substrates are often rotated during deposition to ensure a more uniform and even coating across the entire surface.

Understanding the Trade-offs

Like any technical process, vacuum evaporation has distinct advantages and limitations that make it suitable for some applications but not others.

Advantage: Deposition Speed

One of the most significant advantages of thermal evaporation is its high deposition rate. The process can be much faster than other PVD methods like sputtering.

This speed makes it an efficient and economical choice for applications requiring rapid production of thin films, such as coating optics or metallizing plastics.

Advantage: Simplicity and Purity

The equipment for basic thermal evaporation is relatively simple and cost-effective.

Furthermore, because the process only involves heating the source material, it's possible to create very high-purity films, as there are no other process gases or ions involved that could become embedded in the coating.

Limitation: Adhesion and Film Density

The atoms in thermal evaporation arrive at the substrate with relatively low kinetic energy.

This can result in films that have weaker adhesion and lower density compared to those produced by sputtering, where atoms are ejected with much higher force.

Limitation: Coating Complex Alloys

Depositing films from materials that are alloys or compounds can be challenging.

Different elements within the source material may evaporate at different rates due to varying boiling points, making it difficult to maintain the correct chemical composition (stoichiometry) in the final film.

How to Apply This to Your Project

Choosing a deposition method depends entirely on the required properties of your final film. Evaporation and sputtering are the two most common PVD techniques, and the choice between them involves clear trade-offs.

- If your primary focus is rapid deposition of high-purity, single-element films (like aluminum on a mirror): Vacuum evaporation is often the superior and more economical choice.

- If your primary focus is creating dense, durable films with strong adhesion (like hard coatings on tools): Sputtering is generally preferred because the deposited atoms have higher energy.

- If your primary focus is depositing complex alloys or compounds with precise stoichiometry: Sputtering provides far greater control over the final film's composition.

Ultimately, understanding the fundamental difference in how vapor is generated and travels is the key to selecting the right tool for your specific engineering goal.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Heating a source material in a vacuum to create a vapor that condenses on a substrate. |

| Key Principle | Line-of-sight deposition in a high vacuum (10⁻⁵ to 10⁻⁹ Torr). |

| Primary Advantages | High deposition speed, high film purity, and process simplicity. |

| Primary Limitations | Lower film density/adhesion vs. sputtering; difficulty coating complex alloys. |

| Ideal For | Rapid, high-purity coating of single-element films (e.g., aluminum metallization). |

Need to deposit a high-purity thin film for your lab project?

The principles of vacuum evaporation are key to selecting the right equipment for your specific application. At KINTEK, we specialize in providing high-quality lab equipment, including PVD systems, to meet your precise deposition needs. Whether you are coating optics, metallizing substrates, or developing new materials, our expertise ensures you get the right solution for superior results.

Let's discuss your project requirements and find the perfect PVD solution for your laboratory. Contact our experts today to learn how KINTEK can enhance your research and development capabilities.

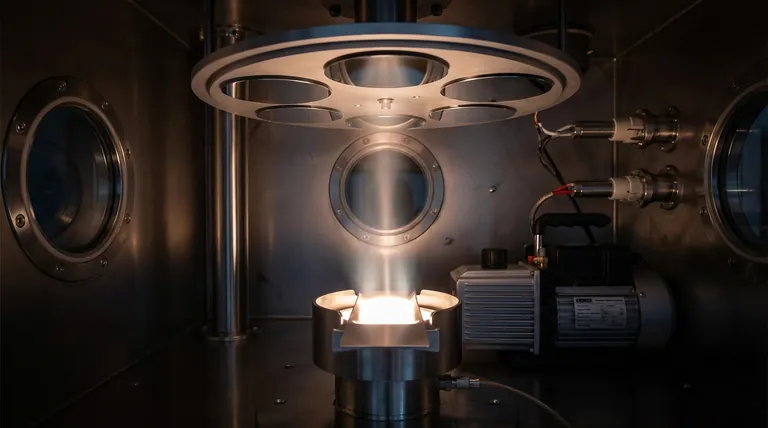

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is thermal effect via evaporation? A Simple Guide to Thin-Film Deposition

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is thermal evaporation technique thin film deposition? A Guide to Simple, Cost-Effective PVD

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications