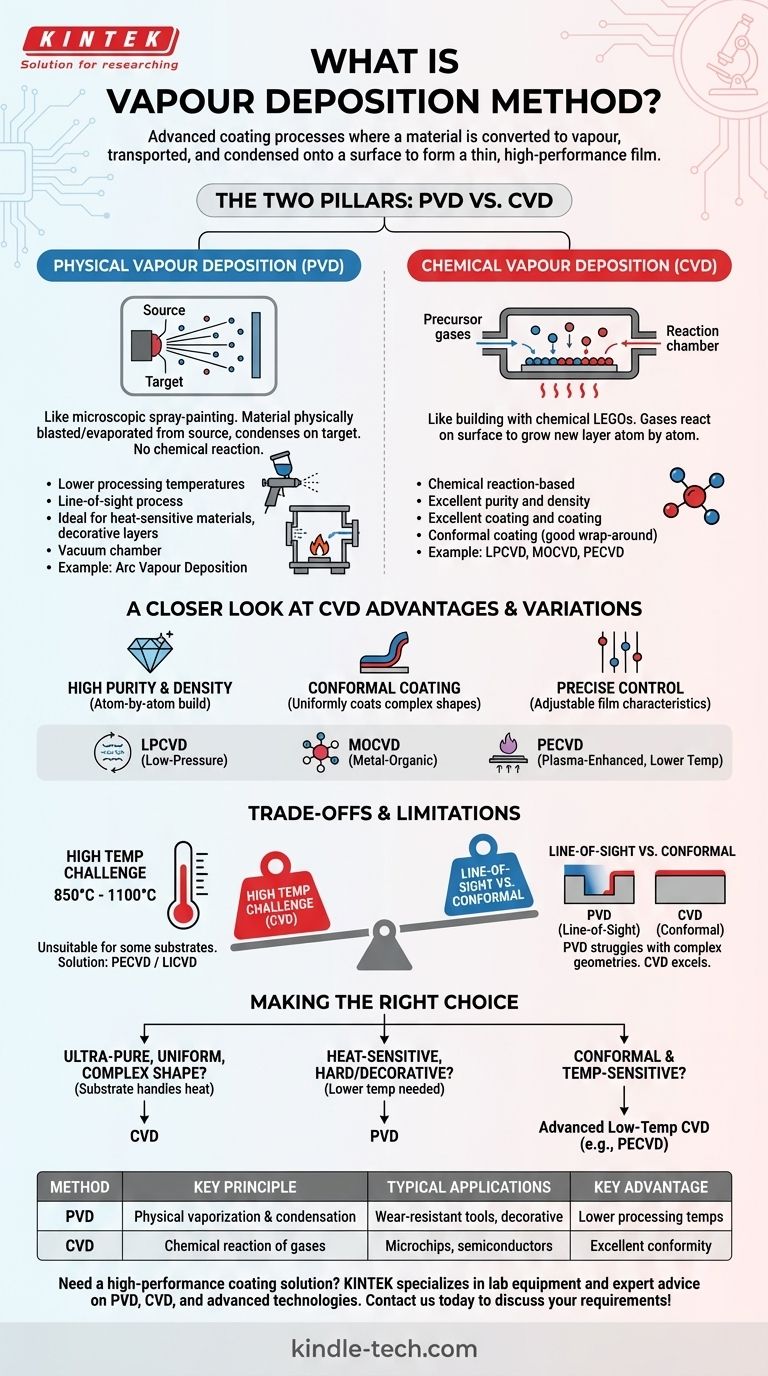

At its core, vapour deposition is a family of advanced coating processes where a material is converted into a gaseous state (a vapour), transported, and then allowed to condense onto a surface to form an extremely thin, high-performance film. These techniques are fundamental to manufacturing everything from microchips to wear-resistant tools. The two primary categories are Chemical Vapour Deposition (CVD) and Physical Vapour Deposition (PVD).

The critical distinction is how the coating is formed. Physical Vapour Deposition (PVD) is like microscopic spray-painting, where a solid material is vaporized and physically settles on a surface. Chemical Vapour Deposition (CVD) is more like building with chemical LEGOs, where gases react on a surface to grow an entirely new layer.

The Two Pillars of Vapour Deposition

To truly understand this technology, you must first grasp the fundamental difference between its two main branches: physical and chemical deposition.

### Physical Vapour Deposition (PVD)

PVD encompasses methods where a material is physically blasted or evaporated from a source, travels through a vacuum, and condenses onto the target workpiece.

There is no chemical reaction involved in forming the film itself.

Methods like arc vapour deposition are a type of PVD. They use a high-energy arc to vaporize and ionize atoms from a source material, ensuring a dense and strongly bonded coating.

### Chemical Vapour Deposition (CVD)

In CVD, the workpiece is placed in a reaction chamber and exposed to one or more volatile precursor gases.

A chemical reaction is then induced on the workpiece's surface, causing a solid material—the desired coating—to be deposited.

This process builds the film atom by atom, resulting in a very pure and uniform layer.

A Closer Look at Chemical Vapour Deposition (CVD)

Since CVD involves the formation of new material directly on the substrate, it offers a unique set of powerful capabilities.

### The Core Advantages

CVD is prized for its ability to produce coatings with exceptionally high purity and density.

Because the precursor is a gas, it can flow into and around complex shapes, providing an excellent, uniform coating known as a "good wrap-around" property.

Engineers have precise control over the film's final characteristics, including its chemical composition, crystal structure, and grain size, by adjusting the deposition parameters.

### Common Variations of CVD

The basic CVD process has been adapted into several specialized techniques to meet different needs.

These include Low-Pressure CVD (LPCVD) for high purity films, Metal-Organic CVD (MOCVD) used extensively in semiconductor manufacturing, and Plasma-Enhanced CVD (PECVD), which uses a plasma to lower the required reaction temperature.

Understanding the Trade-offs and Limitations

No single engineering process is perfect. Choosing the right deposition method requires understanding its inherent compromises.

### The High-Temperature Challenge

Traditional CVD processes often require very high temperatures, typically between 850°C and 1100°C.

This heat is necessary to drive the chemical reaction but makes the process unsuitable for many substrate materials that cannot withstand such thermal stress.

As mentioned, techniques like Plasma-Enhanced CVD (PECVD) or Laser-Induced CVD (LICVD) were developed specifically to overcome this limitation by reducing the deposition temperature.

### Line-of-Sight vs. Conformal Coating

Many PVD processes are considered "line-of-sight," meaning the coating material travels in a straight line from the source to the target. This can make it difficult to uniformly coat hidden surfaces or complex geometries.

CVD, by contrast, excels at creating conformal coatings that perfectly replicate the surface topology, which is a major advantage for intricate parts.

Making the Right Choice for Your Goal

Your specific application and the properties of your base material will dictate the best deposition method.

- If your primary focus is creating an ultra-pure, uniform film that perfectly coats a complex shape: CVD is the definitive choice, provided your substrate material can handle the necessary heat.

- If your primary focus is coating heat-sensitive materials or applying a very hard decorative layer: A PVD method is often the superior option due to its lower processing temperatures and high deposition rates.

- If you need the conformal coating benefits of CVD on a temperature-sensitive material: Your best option is to investigate an advanced, lower-temperature variant like Plasma-Enhanced CVD (PECVD).

Ultimately, selecting the correct vapour deposition technique is about matching the process capabilities to your specific engineering goal.

Summary Table:

| Method | Key Principle | Typical Applications | Key Advantage |

|---|---|---|---|

| PVD (Physical Vapour Deposition) | Physical vaporization and condensation of a material. | Wear-resistant tools, decorative coatings. | Lower processing temperatures. |

| CVD (Chemical Vapour Deposition) | Chemical reaction of gases on a surface to form a coating. | Microchips, semiconductors. | Excellent conformity on complex shapes. |

Need a high-performance coating solution for your lab or production line? The right vapour deposition technique is critical for your project's success. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice on PVD, CVD, and other advanced coating technologies. Let our experts help you select the ideal process for your specific material and application goals. Contact us today to discuss your requirements!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty