At its core, a hydraulic press is a system built from high-strength steel and powered by a fluid. Its essential components include a rigid mainframe, interconnected hydraulic cylinders with pistons, a pump to create pressure, and specialized hydraulic oil to transmit force throughout the system.

A hydraulic press is more than a collection of parts; it's a system designed to exploit a fundamental law of physics. The choice of materials—primarily robust steel for the structure and an incompressible fluid like oil—is entirely dictated by the need to contain and transmit immense pressure efficiently.

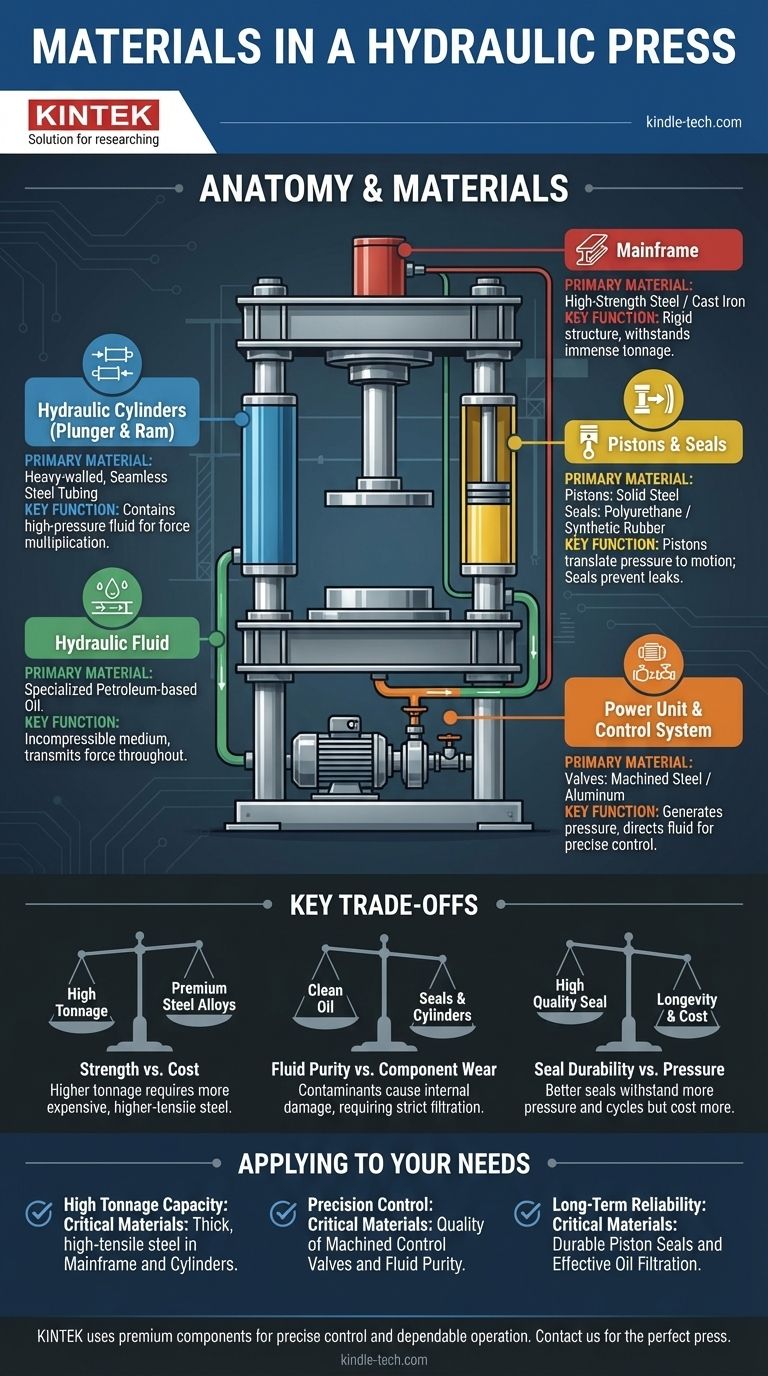

The Anatomy of a Hydraulic Press

To understand the machine, you must first understand its constituent parts and the materials chosen for their specific roles. Each component is engineered to handle extreme forces.

The Mainframe: The Structural Skeleton

The mainframe, or frame, is the backbone of the press. Its sole function is to provide a rigid structure that can withstand the immense tonnage the press generates without bending or failing.

This component is almost always constructed from high-strength, fabricated steel plates or sometimes cast iron for smaller models. Its design ensures all forces are contained and directed into the workpiece.

The Hydraulic Cylinders: The Heart of Force Multiplication

The press's power comes from a set of two interconnected cylinders: a small one often called the plunger and a much larger one called the ram. This is where force multiplication occurs.

These cylinders are made from heavy-walled, seamless steel tubing that is honed and polished internally to an extremely smooth finish. This precision is critical for the piston to travel smoothly and for the seals to prevent leaks under pressure.

The Pistons and Seals: Translating Pressure into Motion

A piston is a solid steel cylinder that fits perfectly inside the hydraulic cylinder. It is the component that moves and applies the force directly to the tooling or workpiece.

The most critical—and often most fragile—part is the piston seal. These are made from durable, flexible materials like polyurethane or specialized synthetic rubber. Their job is to contain the high-pressure fluid, preventing any loss of force.

The Hydraulic Fluid: The Force-Transmitting Medium

The "blood" of the system is the hydraulic fluid, which is almost always a specialized, petroleum-based oil.

This fluid is chosen because it is virtually incompressible. When the pump applies pressure to the fluid in the small plunger cylinder, that pressure is transmitted equally throughout the fluid, pushing on the large ram piston with multiplied force.

The Power Unit and Control System: The Brains and Brawn

The power unit consists of an electric motor connected to a hydraulic pump. The pump is the brawn of the operation, drawing oil from a reservoir and forcing it into the system to create pressure.

This pressure and flow are managed by the hydraulic control system, a series of valves and pipes. These valves, typically made of machined steel and aluminum, direct the fluid to either extend or retract the main ram, giving the operator precise control.

Understanding the Key Trade-offs

The material selection in a hydraulic press is a deliberate engineering decision based on balancing performance, longevity, and cost.

Strength vs. Cost

The tonnage rating of a press is directly related to the thickness and quality of the steel used in its frame and cylinders. Higher-tonnage presses require more expensive, higher-tensile steel alloys to safely manage the forces involved.

Fluid Purity vs. Component Wear

The hydraulic oil is the lifeblood, but it can also be a source of failure. Contaminants like dust or metal shavings can act like sandpaper on the internal components, destroying seals and scoring the cylinder walls. This makes fluid filtration and purity paramount.

Seal Durability vs. Pressure

The seals are the primary wear item in any hydraulic system. A higher-quality seal material can withstand greater pressure and more cycles before it fails, but it comes at a higher cost. This trade-off directly impacts the machine's maintenance schedule and long-term reliability.

Applying This to Your Needs

Understanding these materials helps you evaluate the capability and quality of any press based on your specific goals.

- If your primary focus is high tonnage capacity: The critical materials are in the mainframe and cylinder walls, which must be made of thick, high-tensile steel to prevent failure.

- If your primary focus is precision control: The quality of the machined hydraulic control valves and the purity of the hydraulic fluid are paramount for smooth, repeatable operation.

- If your primary focus is long-term reliability: Pay close attention to the material quality of the piston seals and the system's oil filtration, as these are the most common points of failure.

By understanding how these fundamental materials work together, you can better diagnose issues, evaluate equipment, and appreciate the engineering behind the force.

Summary Table:

| Component | Primary Material | Key Function |

|---|---|---|

| Mainframe | High-Strength Steel / Cast Iron | Provides rigid structure to withstand immense tonnage |

| Hydraulic Cylinders | Heavy-walled, Seamless Steel Tubing | Contains high-pressure fluid for force multiplication |

| Pistons | Solid Steel | Translates hydraulic pressure into linear motion |

| Piston Seals | Polyurethane / Synthetic Rubber | Prevents fluid leaks under extreme pressure |

| Hydraulic Fluid | Specialized Petroleum-based Oil | Transmits force as an incompressible medium |

| Control Valves | Machined Steel / Aluminum | Directs fluid flow for precise operation control |

Need a reliable hydraulic press for your lab or production facility? The materials and engineering behind your equipment are critical to its performance, safety, and longevity. KINTEK specializes in high-quality lab equipment, including robust hydraulic presses built with premium components for precise control and dependable operation. Let our experts help you select the perfect press for your specific application—whether your priority is high tonnage, precision, or long-term reliability.

Contact KINTEK today to discuss your requirements and get a personalized solution!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces

- How much force can a hydraulic press exert? Understanding its immense power and design limits.