At its core, blacksmithing is possible with any metal that can be heated to a plastic, workable state without fracturing. While many metals can theoretically be forged, the most common and practical choices are iron and various types of steel. Other non-ferrous metals like copper, bronze, and brass can also be worked, but they behave very differently from the steel that defines the craft.

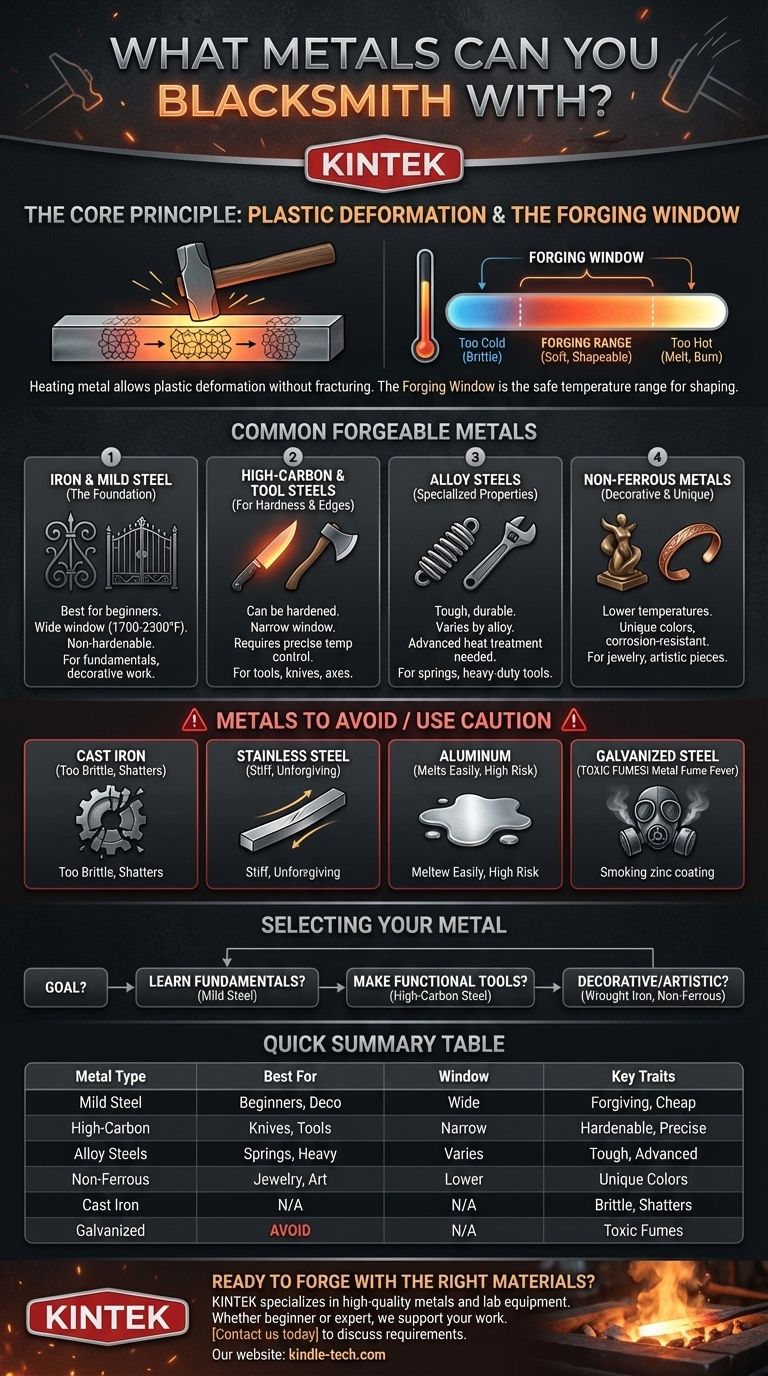

The suitability of a metal for blacksmithing is determined by its forging window—the temperature range where it is soft enough to shape but not so hot that it is damaged. A wide, forgiving forging window is what makes a metal practical for a smith.

The Defining Trait: What Makes a Metal Forgeable?

To select the right material, you must first understand the underlying principle that makes forging possible. It's about changing a metal's shape, not its state.

Understanding Plastic Deformation

Blacksmithing works by heating a metal until its internal crystal structure has enough energy to move and rearrange without breaking. This is called plastic deformation.

This is the opposite of a brittle material, like glass or cast iron, which will simply fracture under the force of a hammer blow, regardless of its temperature.

The Critical Role of the "Forging Window"

The forging window is the usable temperature range for a specific metal. Below this range, the metal is too hard and risks cracking. Above this range, the metal can spark, burn, or even melt, destroying its structural integrity.

Mild steel, for example, has a very wide and forgiving forging window (roughly 1700-2300°F or 900-1250°C), making it ideal for beginners. High-carbon steels have a much narrower window, demanding precise temperature control.

The Difference from Casting or Welding

Forging is distinct from other metalworking processes. Casting involves melting metal into a liquid and pouring it into a mold. Welding joins pieces by melting their edges together.

Forging uniquely shapes the metal while it remains in a solid (though plastic) state. This process refines the metal's internal grain structure, which can dramatically increase its strength and durability.

Common Metals Used in Blacksmithing

While the list of forgeable metals is long, a few categories cover the vast majority of work done in a smithy.

Iron and Mild Steel: The Foundation

These are the quintessential materials for blacksmithing. Mild steel (like A36 or 1018) is cheap, widely available, and has the most forgiving forging window.

It's the ideal material for learning fundamentals and is used for everything from decorative scrollwork to sturdy gates and furniture. Its primary limitation is that it cannot be hardened to hold a sharp edge.

High-Carbon and Tool Steels: For Hardness and Edge-Holding

Adding carbon to steel creates a material that can be hardened and tempered. This process is what allows a smith to create functional tools.

These steels (like the 10-series, e.g., 1075, 1084, 1095) are the standard for knives, axes, chisels, and hammers. They require more careful temperature management to avoid overheating and ruining the carbon content.

Alloy Steels: Specialized Properties

Alloy steels include other elements besides iron and carbon, such as chromium, manganese, or nickel. A common example is 5160, a spring steel known for its exceptional toughness.

These alloys are chosen for specific applications requiring high durability, like vehicle leaf springs or heavy-duty tools, but their unique properties often require more advanced heat-treating procedures.

Non-Ferrous Metals: A Different Challenge

Metals like copper, brass, and bronze are also forgeable but behave very differently from steel. They are worked at much lower temperatures and do not display the same bright color cues when heated.

Their unique colors and resistance to corrosion make them popular for jewelry, decorative inlays, and artistic sculptures.

Metals to Approach with Caution (or Avoid)

Not all metals are suitable for the forge, and some pose significant risks if handled improperly.

Cast Iron: Too Brittle to Forge

The extremely high carbon content in cast iron makes it brittle. When struck with a hammer, even at a bright heat, it will shatter rather than deform.

Stainless Steel: Stiff and Unforgiving

While some grades of stainless steel can be forged, they are incredibly stiff even at forging temperatures. They require much more force to move and have a very narrow working window, making them difficult for most smiths.

Aluminum: A High Risk of Melting

Aluminum and its alloys have a melting point that is very close to their forging temperature. It is incredibly easy to overheat and accidentally turn your workpiece into a puddle on the floor.

Galvanized Steel: A Critical Safety Hazard

Never heat galvanized steel in a forge. The zinc coating will vaporize at forging temperatures, releasing fumes that are highly toxic. Inhaling this fume causes a severe illness known as "metal fume fever," with symptoms similar to a severe flu.

Selecting the Right Metal for Your Project

Your material choice should be driven by the intended function of the final piece.

- If you are a beginner learning the fundamentals: Start with mild steel. Its forgiving nature and low cost are ideal for practicing basic techniques without worry.

- If your goal is to make functional tools or knives: Use a high-carbon steel like 1084 or 5160, as these can be properly heat-treated to hold a durable edge.

- If you are creating decorative or artistic pieces: Consider wrought iron for a traditional look, or explore the unique colors of copper, brass, and bronze for aesthetic appeal.

Choosing the correct metal is the first step in successfully translating your vision from an idea into a durable, forged object.

Summary Table:

| Metal Type | Best For | Forging Window | Key Characteristics |

|---|---|---|---|

| Mild Steel | Beginners, decorative work | Wide (1700-2300°F) | Forgiving, cheap, cannot be hardened |

| High-Carbon Steel | Knives, tools, axes | Narrow | Can be hardened, requires precise temperature control |

| Alloy Steels | Springs, heavy-duty tools | Varies | Tough, requires advanced heat treatment |

| Non-Ferrous (Copper, Brass) | Jewelry, decorative art | Lower temperatures | Unique colors, corrosion-resistant |

| Cast Iron | Not recommended for forging | N/A | Brittle, will shatter when struck |

| Galvanized Steel | Avoid - toxic fumes | N/A | Zinc coating vaporizes, causes metal fume fever |

Ready to start your next blacksmithing project with the right materials? KINTEK specializes in providing high-quality metals and lab equipment for all your forging needs. Whether you're a beginner working with mild steel or an expert crafting tools with high-carbon steel, we have the materials and expertise to support your work. Contact us today to discuss your specific metal requirements and let us help you bring your forged creations to life!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between a muffle furnace and a normal furnace? Ensuring Sample Purity with Indirect Heating

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method

- What are the conditions for a muffle furnace? Ensure Safety, Performance, and Longevity

- What is the difference between muffle furnace and air oven? Choose the Right Tool for Your Thermal Process

- What are the disadvantages of a muffle furnace? Understanding the Trade-offs for Your Lab