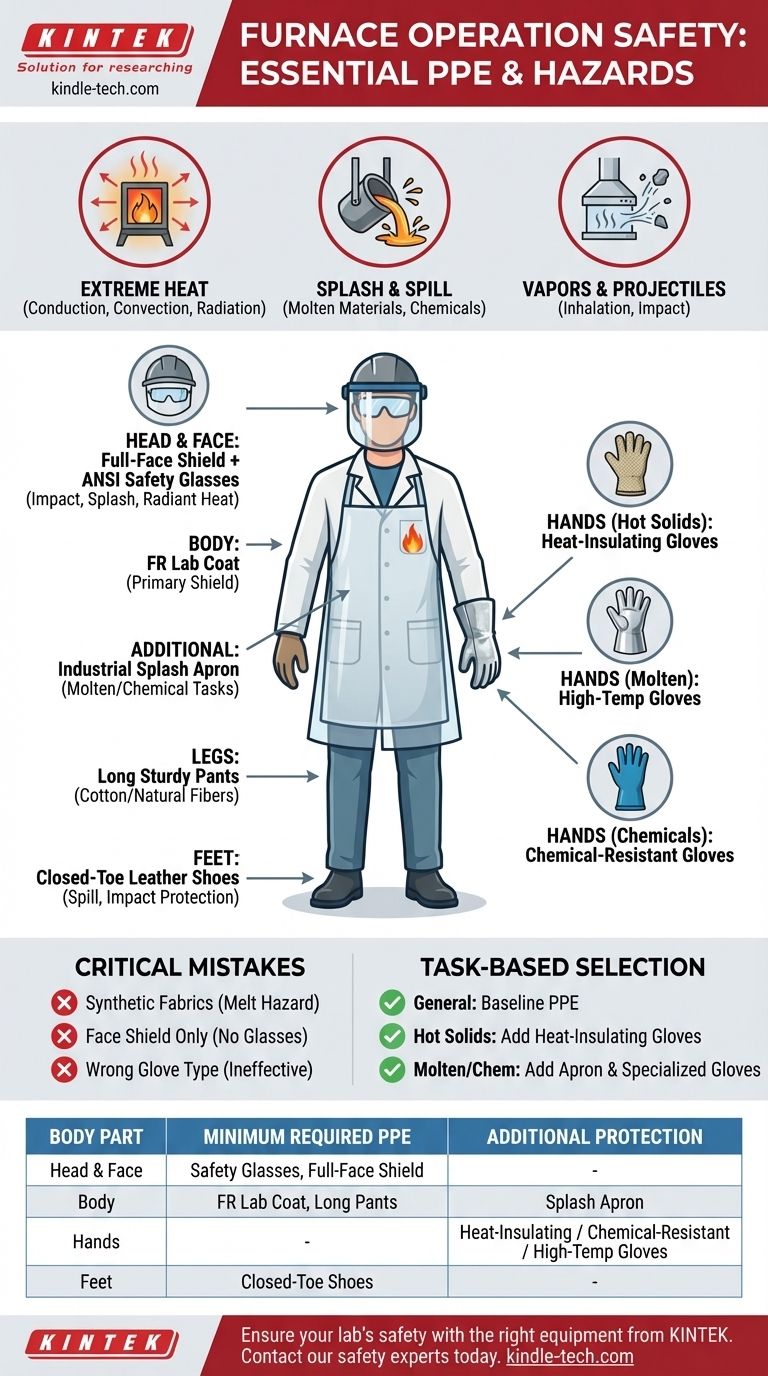

At a minimum, operating a furnace requires long pants, closed-toe shoes, a flame-resistant lab coat, and a full-face shield worn over safety glasses. Depending on the specific task, you will also need an appropriate splash apron and either heat-insulating or chemical-resistant gloves. This equipment forms a complete system designed to protect you from the severe thermal and chemical hazards inherent in furnace work.

The core principle of furnace safety is not just wearing PPE, but selecting the correct PPE for the specific task. Your gear is the only barrier between you and potentially life-altering injuries from extreme heat, molten splashes, or chemical reactions.

Why Furnace Work Demands Rigorous PPE

Operating a furnace exposes you to multiple, simultaneous hazards. Simply being near the equipment is a risk, and handling materials introduces even greater danger. Understanding these threats clarifies why each piece of PPE is non-negotiable.

The Primary Hazard: Extreme Heat

Furnaces produce intense heat that travels in three ways: conduction (direct contact), convection (hot air), and radiation (infrared waves). Your PPE must be able to shield you from all three to prevent severe burns.

The Splash and Spill Danger

Many furnace applications involve molten materials (like metals) or heated chemical solutions. A splash can cause catastrophic burns and may react violently with inappropriate clothing materials.

The Unseen Risks: Vapors and Projectiles

Heating materials can release hazardous vapors that require respiratory protection (a separate consideration from standard PPE). Additionally, rapid heating or material failures can create unexpected projectiles, making eye and face protection essential.

A Layer-by-Layer Guide to Furnace PPE

Effective protection comes from a layered system, where each component has a specific job.

Head and Face: Your First Line of Defense

A full-face shield is mandatory. It is your primary defense against radiant heat and splashes. However, it does not seal around the eyes.

For this reason, ANSI-rated safety glasses must always be worn underneath the face shield. This provides crucial impact protection from any debris that might get past the shield.

Body: Shielding from Heat and Splashes

Your primary body covering should be a flame-resistant (FR) lab coat. Standard cotton or polyester lab coats offer minimal protection and can melt or ignite.

For tasks involving potential splashes of molten material or chemicals, an industrial apron made of leather, aluminized fabric, or another heat/chemical-resistant material must be worn over the lab coat.

Finally, long, sturdy pants made from natural fibers like cotton denim are required. They provide a final layer of insulation and splash protection for your legs.

Hands: Choosing the Right Glove for the Task

Hand protection is highly task-dependent. Never use a wet glove, as the trapped moisture can turn to steam instantly, causing a severe burn.

For handling hot, dry objects, use heat-insulating gloves (often made of materials like Terry-cloth or Kevlar).

For handling molten materials, you need specialized high-temperature gloves (e.g., aluminized or Zetex) designed to shed splashes.

For working with heated chemicals, select chemical-resistant gloves with a thermal liner, ensuring they are rated for the specific chemical and temperature you are using.

Feet: The Foundation of Safety

Closed-toe shoes, preferably made of leather or another durable material, are essential. They protect your feet from small spills, splashes, and dropped objects. Canvas or mesh shoes offer no meaningful protection and should never be worn.

Common Mistakes and Critical Considerations

Knowing what not to do is as important as knowing what to do. Avoid these common but dangerous mistakes.

Synthetic Fabrics Are a Fire Hazard

Never wear clothing made from synthetic materials like polyester, nylon, or spandex. These fabrics can melt when exposed to high heat, sticking to your skin and causing horrific burns. Stick to natural fibers like cotton or wool.

A Face Shield Is Not a Substitute for Safety Glasses

A face shield alone is not adequate eye protection. It is designed to protect your whole face from heat and splashes. Always wear safety glasses underneath to protect against impact and smaller particles.

Not All Gloves Are Created Equal

Using the wrong glove is extremely dangerous. A standard leather work glove will not protect you from a molten metal splash, and a heat-insulating glove may degrade upon contact with certain chemicals. Always verify your glove is rated for the specific hazard.

Making the Right Choice for Your Task

Use this guide to select the appropriate level of PPE for your specific work.

- If your primary focus is general furnace operation or observation: Your baseline is an FR lab coat, long cotton pants, leather shoes, safety glasses, and a full-face shield.

- If your primary focus is handling hot, solid materials from the furnace: Add a pair of high-temperature, heat-insulating gloves to your baseline equipment.

- If your primary focus is working with molten materials or hazardous chemicals: Augment your baseline with a specialized apron (leather/aluminized) and task-specific gloves designed for molten splashes or chemical resistance.

Ultimately, personal protective equipment is your last line of defense when all other safety controls fail.

Summary Table:

| Body Part | Minimum Required PPE | Additional Protection for Specific Tasks |

|---|---|---|

| Head & Face | Safety Glasses, Full-Face Shield | - |

| Body | Flame-Resistant Lab Coat, Long Pants | Splash Apron (for molten materials/chemicals) |

| Hands | - | Heat-Insulating Gloves (hot solids) / Chemical-Resistant Gloves (chemicals) / High-Temp Gloves (molten materials) |

| Feet | Closed-Toe Shoes (e.g., leather) | - |

Ensure your lab's safety with the right equipment from KINTEK.

Operating a furnace safely requires not just any PPE, but the correct PPE designed for extreme temperatures and hazardous materials. KINTEK specializes in providing reliable lab equipment and consumables, including high-temperature gloves, flame-resistant apparel, and safety gear tailored for laboratory environments.

Protect your team from severe thermal and chemical hazards—contact our safety experts today for a consultation on outfitting your lab with the right protective solutions.

Visual Guide

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- 1700℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

People Also Ask

- Can a crucible withstand heat? Yes, with the right material and thermal properties.

- What are crucibles used for in lab? Ensuring Accurate, High-Temperature Sample Analysis

- What is the best type of crucible? The Answer Depends on Your Application's Needs

- Why is a PTFE crucible preferred for plasma etching? Ensure Chemical Integrity and Targeted Action

- Is a crucible a lab equipment? A Guide to High-Temperature Containers for Labs and Foundries