Before use, an electrode holder must undergo two primary pretreatment steps: a thorough cleaning to remove contaminants and a mechanical inspection to ensure all components function correctly. These steps are essential for establishing a reliable electrical connection and preventing experimental artifacts.

The core purpose of pretreating an electrode holder is to eliminate two fundamental sources of experimental error: chemical contamination from dirty surfaces and electrical noise from poor mechanical connections. Proper preparation ensures your results are accurate and reproducible.

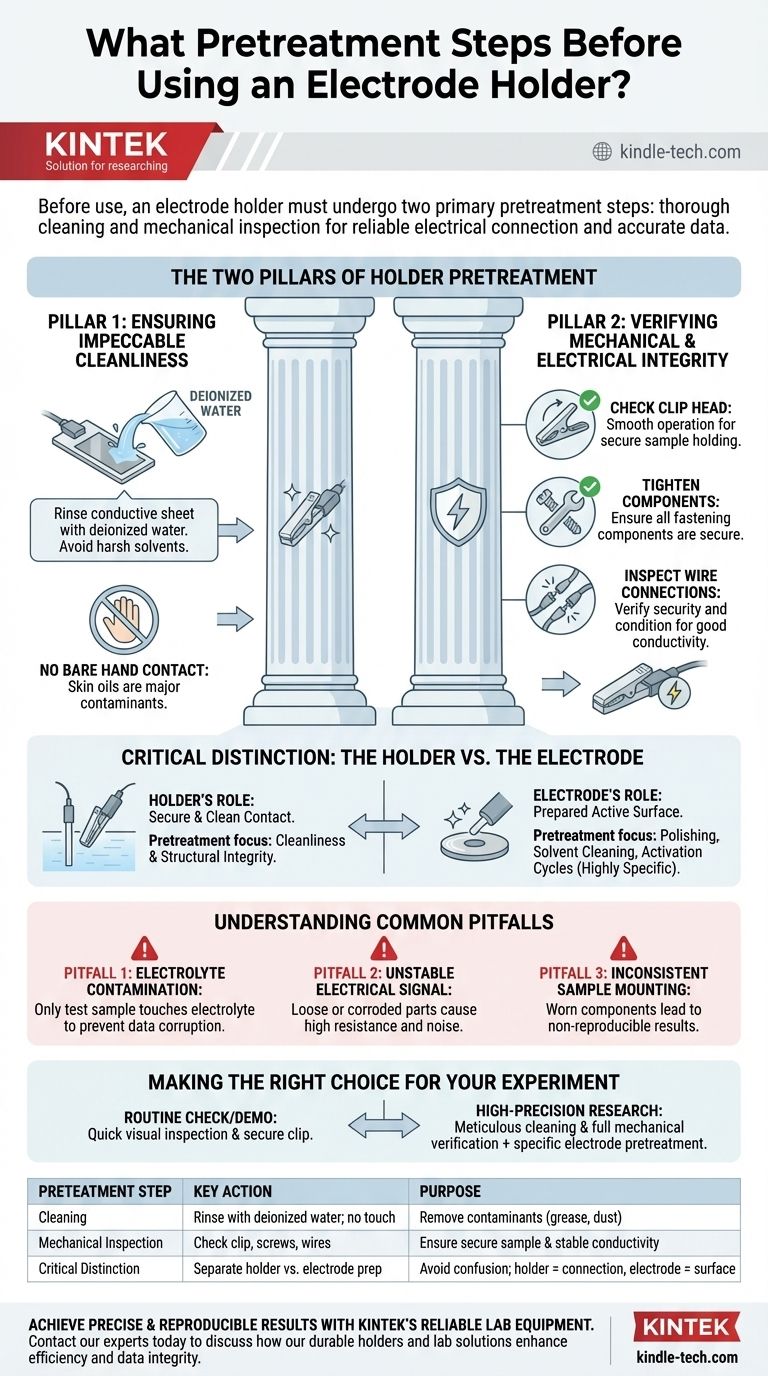

The Two Pillars of Holder Pretreatment

The goal of pretreating an electrode holder is simple: ensure it holds the sample securely and provides a clean, stable electrical path. This preparation can be broken down into two key areas.

Pillar 1: Ensuring Impeccable Cleanliness

Contaminants are the primary enemy of reliable electrochemical measurements. Grease, dust, or residual chemicals can alter the intended reaction or create a faulty electrical contact.

To prepare the holder, first ensure the conductive sheet—the part that makes electrical contact with your sample—is completely clean.

If the sheet appears dirty, it can be rinsed with deionized water and gently dried. Avoid using harsh solvents that could damage plastic components of the holder.

Crucially, avoid touching the conductive surfaces or the sample with bare hands. Skin oils are a significant source of contamination.

Pillar 2: Verifying Mechanical and Electrical Integrity

A poor mechanical connection is a direct path to noisy data or a failed experiment. Before every use, perform a quick physical inspection.

Check that the clip head or clamping mechanism opens and closes smoothly. A faulty clip cannot hold the sample securely, leading to an inconsistent connection.

Verify that all fastening components, such as screws or clamps, are in good condition and can be tightened properly. Loose connections are a common source of electrical noise.

Finally, inspect the wire connections to the holder. Ensure they are secure and show no signs of aging, fraying, or corrosion, as this can impede good electrical conductivity.

Critical Distinction: The Holder vs. The Electrode

A common point of confusion is failing to distinguish between preparing the holder and preparing the electrode (the sample being held). They are two separate but equally important tasks.

The Holder's Role: Secure and Clean Contact

The electrode holder has one job: to provide a stable mechanical and electrical connection to the test sample, isolated from the electrolyte. Its pretreatment focuses entirely on cleanliness and structural integrity.

The Electrode's Role: A Prepared Active Surface

The electrode itself—whether a gold disc, a piece of foil, or another material—is the active surface where the electrochemistry occurs. Its pretreatment is often far more complex.

This may involve polishing the surface to a mirror finish with alumina powder, cleaning it with specific organic solvents like ethanol or acetone, or performing electrochemical activation cycles to create a known starting state.

These steps are highly specific to the electrode material and the experiment being conducted. Never assume that preparing the holder is a substitute for properly preparing the electrode surface.

Understanding the Common Pitfalls

Proper pretreatment directly prevents the most common issues that invalidate experimental results.

Pitfall 1: Electrolyte Contamination

One of the most critical rules is that only the test sample should touch the electrolyte solution. If any part of the electrode holder comes into contact with the electrolyte, it can introduce metallic ions or other contaminants, corrupting your data.

Pitfall 2: Unstable Electrical Signal

A loose screw, a dirty contact point, or a corroded wire will create a high-resistance connection. This manifests as noise in your data, unstable potential or current readings, and a general lack of reproducibility.

Pitfall 3: Inconsistent Sample Mounting

If the holder's clip is worn or the screws are stripped, you cannot mount the sample in the same way for each experiment. This variation in exposed surface area or contact pressure makes it impossible to compare results between tests.

Making the Right Choice for Your Experiment

Your level of preparation should match the sensitivity of your experiment.

- If your primary focus is a routine quality check or a simple demonstration: A quick visual inspection for cleanliness and a check that the clip is secure may be sufficient.

- If your primary focus is a high-precision research experiment: You must meticulously clean all conductive surfaces, verify every mechanical connection, and perform the separate, highly specific pretreatment required for your electrode material.

Ultimately, disciplined preparation of your equipment is the foundation for generating data you can trust.

Summary Table:

| Pretreatment Step | Key Action | Purpose |

|---|---|---|

| Cleaning | Rinse conductive sheet with deionized water; avoid touching surfaces. | Remove contaminants (grease, dust) to prevent experimental artifacts. |

| Mechanical Inspection | Check clip head, fastening components, and wire connections for integrity. | Ensure secure sample mounting and stable electrical conductivity. |

| Critical Distinction | Separate holder preparation from electrode surface pretreatment. | Avoid confusion; holder provides connection, electrode is the active surface. |

Achieve precise and reproducible electrochemical results with KINTEK's reliable lab equipment. Proper electrode holder pretreatment is just the first step—ensure your entire workflow is supported by high-quality instruments. KINTEK specializes in durable electrode holders, consumables, and lab solutions designed for accuracy and longevity. Contact our experts today to discuss how our products can enhance your laboratory's efficiency and data integrity.

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

- Customizable XRD Sample Holders for Diverse Research Applications

- Button Battery Case for Battery Lab Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How does a custom PTFE electrode holder contribute to the accuracy of immersion tests? Ensure Precise Steel Analysis

- Why is it necessary to utilize PTFE sample holders in electroless nickel plating? Ensure Process Integrity

- What are the recommended and prohibited cleaning methods for the PTFE electrode stand? Protect Your Lab Equipment

- What materials are the sample holders made of? Engineered with PTFE and PEEK for Purity

- Why is high-purity PTFE selected as the sample holder for zirconium alloy corrosion tests? Gain Unmatched Data Accuracy