At its core, a hydraulic press is a foundational tool of modern manufacturing, responsible for creating an astonishingly wide range of everyday products. From the metal body panels of your car and the casing of your washing machine to composite aircraft components and even the compressed powders in cosmetics, these machines use immense, controlled force to shape, form, and assemble materials.

A hydraulic press is not defined by the specific products it makes, but by its fundamental capability: applying massive, uniform pressure at any point in its operational stroke. This unique ability makes it indispensable for forging, stamping, molding, and compacting a vast array of materials.

The Core Principle: How a Hydraulic Press Works

To understand what a hydraulic press can create, you must first understand how it generates such incredible force. Its operation is based on a simple but powerful law of physics.

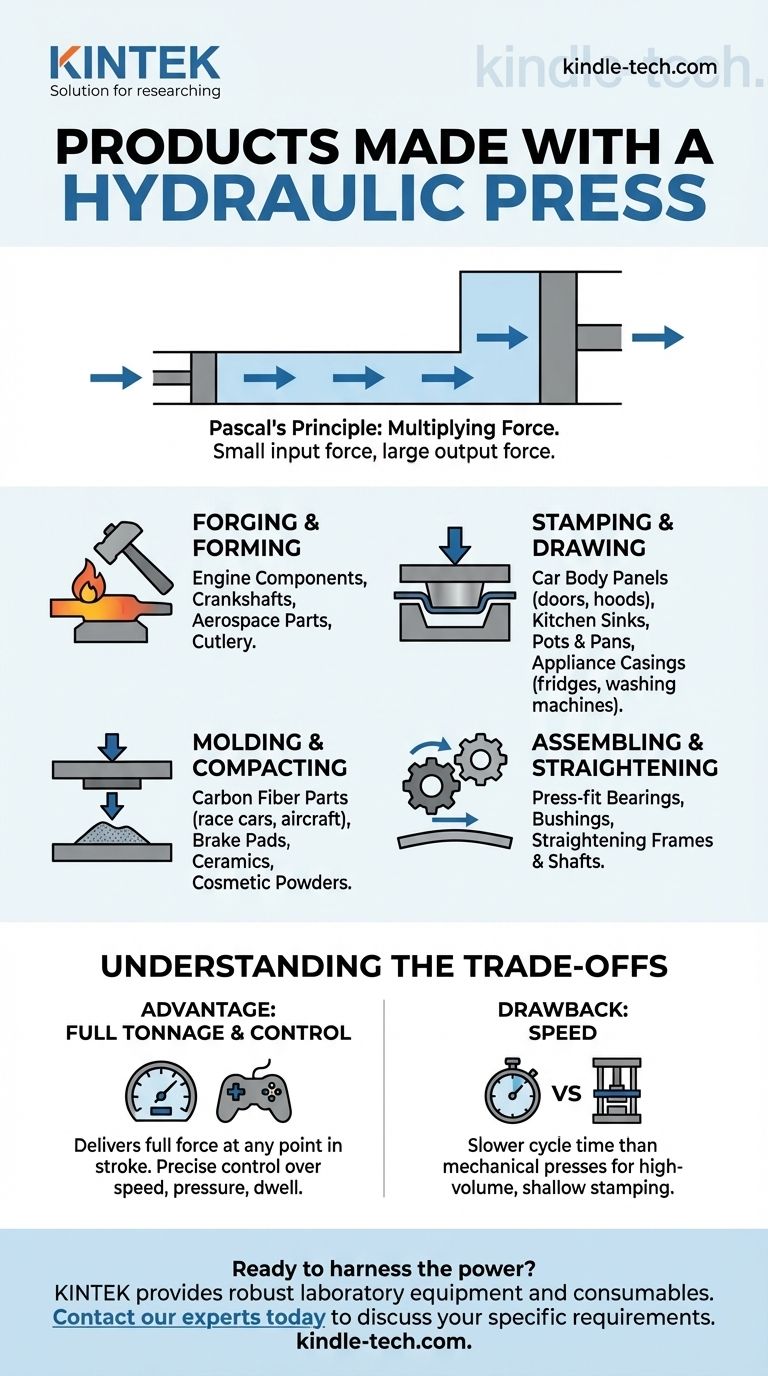

Pascal's Principle: Multiplying Force

The machine's power comes from Pascal's Principle, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

A hydraulic press uses a pump to push a small amount of hydraulic fluid into a small cylinder (the plunger). This action creates pressure, which is then transferred through the fluid to a much larger cylinder (the ram). Because the ram has a significantly larger surface area, the initial pressure is multiplied into a massive output force.

Key Components

The system consists of a few primary parts working in concert. A hydraulic power unit contains the pump and fluid. Control valves direct the flow of high-pressure fluid. This fluid acts on a hydraulic cylinder or ram, which is mounted within a strong mainframe that withstands the immense forces generated.

From Raw Materials to Finished Goods: Key Applications

The value of a hydraulic press lies in its versatility. It is used across dozens of manufacturing processes, each creating different types of products.

Forging and Forming Metals

This involves shaping solid blocks or billets of metal. The slow, sustained force of a hydraulic press is perfect for forcing metal to flow into a die.

Products include critical automotive parts like engine components, crankshafts, and suspension arms, as well as high-strength aerospace components and even simple items like cutlery.

Stamping and Drawing

This process turns flat sheets of metal into three-dimensional objects. A "deep draw" operation, where a sheet is pushed deep into a cavity, is a specialty of hydraulic presses.

This is how kitchen sinks, pots and pans, and the metal casings for appliances like refrigerators, ovens, and washing machines are made. It's also used for creating automotive body panels like doors, hoods, and fenders.

Molding and Compacting

Hydraulic presses are essential for creating products from materials that need to be compacted under high pressure and often heat.

This includes molding composite materials like carbon fiber parts for race cars and aircraft, manufacturing brake pads, creating dense ceramic components, and even compacting cosmetic powders into pans. Scrap metal is also compacted into dense bales for recycling.

Assembling and Straightening

The controlled force is also ideal for assembly. This includes press-fitting bearings onto shafts, inserting bushings, or joining multiple parts with extreme precision and force. It is also a primary tool for straightening bent or warped metal frames, plates, and shafts.

Understanding the Trade-offs

While incredibly powerful, a hydraulic press is not the right tool for every job. Understanding its advantages and disadvantages is key to appreciating its role.

The Advantage of Full Tonnage

The defining feature of a hydraulic press is its ability to deliver its full rated force at any point in the ram's stroke. A mechanical press, by contrast, only achieves maximum force at the very bottom of its stroke. This makes hydraulic presses ideal for jobs requiring sustained pressure, like deep drawing or forging.

The Benefit of Control

Modern hydraulic presses offer precise control over ram speed, pressure, stroke distance, and dwell time. This allows for complex operations and fine-tuning the process for delicate or difficult materials.

The Drawback of Speed

Generally, hydraulic presses have a slower cycle time compared to mechanical presses. For high-volume, shallow stamping operations (like producing millions of small washers), a mechanical press is often the more efficient choice.

Making the Right Choice for Your Process

The decision to use a hydraulic press is driven entirely by the requirements of the manufacturing task.

- If your primary focus is shaping thick metal or requiring immense, sustained force: A hydraulic press is ideal for forging and deep drawing operations where materials must be forced to flow.

- If your primary focus is creating complex parts from composites or powders: The controlled, even pressure of a hydraulic press is essential for molding and compacting applications.

- If your primary focus is high-speed, repeatable stamping of thinner materials: A mechanical press is often a more efficient choice for high-volume production runs.

Ultimately, the hydraulic press is a master of controlled power, enabling the creation of parts that demand immense force and precision.

Summary Table:

| Manufacturing Process | Common Products Made |

|---|---|

| Forging & Forming | Engine parts, crankshafts, aerospace components, cutlery |

| Stamping & Drawing | Car body panels, kitchen sinks, appliance casings, pots/pans |

| Molding & Compacting | Carbon fiber parts, brake pads, ceramics, cosmetic powders |

| Assembling & Straightening | Press-fit bearings, straightening metal frames/shafts |

Ready to harness the power of a hydraulic press for your manufacturing needs?

KINTEK specializes in providing robust laboratory equipment and consumables. Whether your process involves material testing, sample preparation, or R&D, our solutions are designed to deliver the precision and reliability you need.

Contact our experts today to discuss how we can support your laboratory's specific requirements and help you achieve superior results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming