At its core, heat treatment systematically alters a material's internal microstructure to achieve a desired set of engineering properties. By precisely controlling heating and cooling cycles, you can change a metal's mechanical characteristics, including its hardness, strength, ductility, toughness, and wear resistance. This process can also be used to relieve internal stresses or enhance a material's electrical and magnetic properties.

Heat treatment is not a single process, but a toolkit for achieving a specific engineering outcome. The fundamental principle is managing the trade-off between strength and hardness on one side, and ductility and toughness on the other, to tailor a material for its intended function.

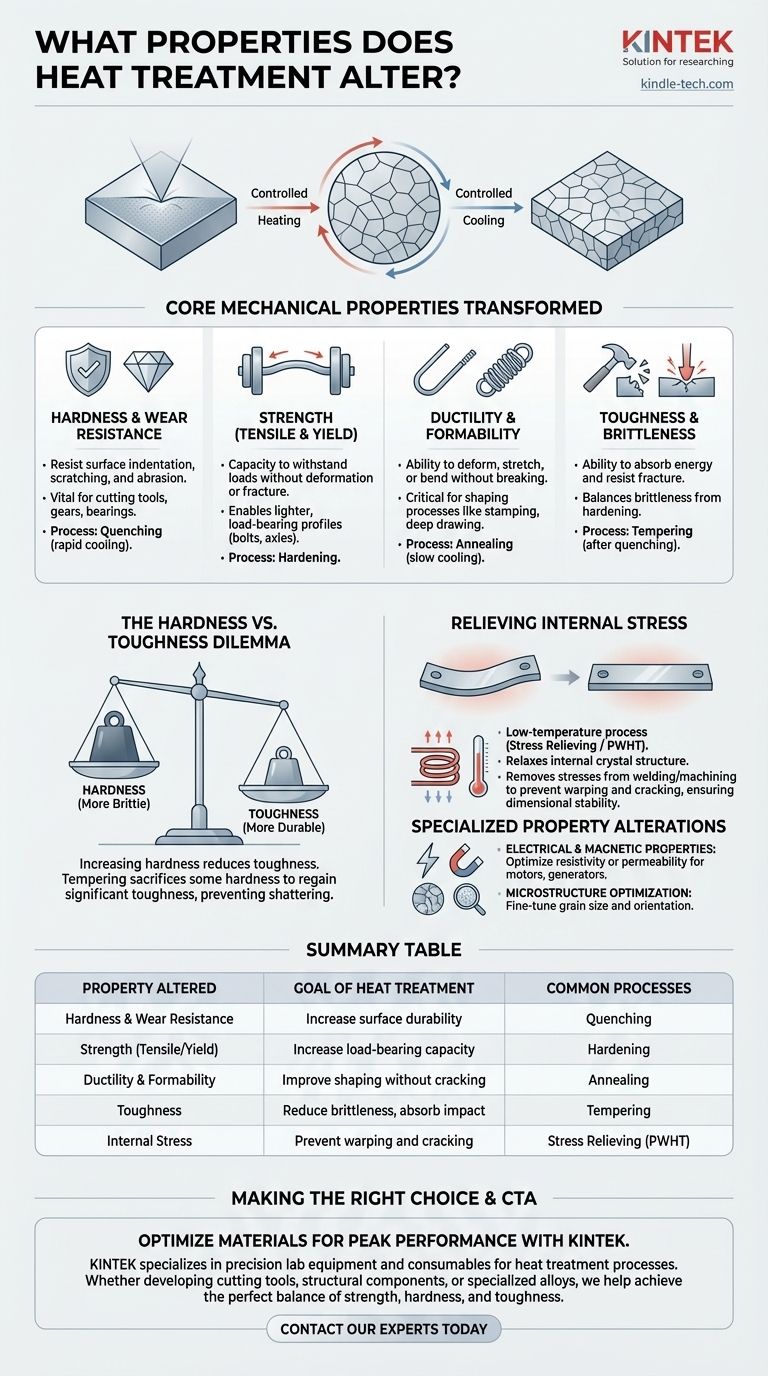

The Core Mechanical Properties Transformed

Heat treatment's primary purpose is to manipulate the mechanical behavior of a material, most commonly steel. Each property can be targeted and modified to suit a specific application.

Hardness and Wear Resistance

Hardness is a material's ability to resist surface indentation, scratching, and abrasion.

Processes like quenching (rapid cooling) create a very hard and brittle microstructure. This is the foundation for creating parts that must withstand significant surface wear, such as cutting tools, gears, and bearings.

Strength (Tensile and Yield)

Strength measures a material's capacity to withstand an applied load without deforming (yield strength) or fracturing (tensile strength).

Hardening processes significantly increase strength. This allows components like structural bolts, axles, and support beams to carry greater loads or be designed in smaller, lighter-weight profiles.

Ductility and Formability

Ductility is a measure of a material's ability to deform, stretch, or bend without breaking.

Processes like annealing, which involve slow cooling, make a material softer and more ductile. This is critical for manufacturing processes like stamping, deep drawing, or wire forming, where the material must be shaped without cracking.

Toughness and Brittleness

Toughness is a material's ability to absorb energy and resist fracturing when subjected to an impact. It is the opposite of brittleness.

While quenching makes steel very hard, it also makes it brittle and prone to shattering. A subsequent process called tempering is almost always applied to reduce this brittleness and restore a calculated amount of toughness, creating a more durable and reliable final part.

Beyond Strength: Relieving Internal Stress

Not all heat treatment is about making a part harder. Sometimes, the goal is to make it more stable and predictable.

Why Internal Stress is a Problem

Manufacturing operations like welding, machining, casting, and cold forming lock internal stresses into a material's structure.

These hidden stresses can cause parts to warp over time, crack unexpectedly during service, or deform during subsequent machining operations.

The Role of Stress Relieving

Low-temperature heat treatments, known as stress relieving or post-weld heat treatment (PWHT), heat the material just enough for its internal crystal structure to relax.

This process does not significantly change the hardness or strength but removes the internal stresses, resulting in a dimensionally stable component that is safe to machine and reliable in service.

Understanding the Trade-offs

Choosing a heat treatment process is always an act of balancing competing properties. Understanding these compromises is essential for making an informed decision.

The Hardness vs. Toughness Dilemma

The most common trade-off in heat treatment is between hardness and toughness.

Increasing a material's hardness almost always reduces its toughness, making it more brittle. A file is extremely hard to resist wear but will snap if bent. This is why a tempering process is so critical—it sacrifices a small amount of hardness to regain a significant amount of toughness.

The Impact on Machinability

A harder material is more difficult and expensive to machine. It causes more rapid tool wear and requires slower machining speeds.

For this reason, complex machining operations are often performed when the material is in its soft, annealed state. The part is only put through its final hardening and tempering cycles after the primary shaping is complete.

Specialized Property Alterations

While less common, heat treatment can also be used to fine-tune non-mechanical properties for specialized applications.

Electrical and Magnetic Properties

For certain alloys, heat treatment can influence the size and orientation of the metallic grains.

This can be used to optimize electrical resistivity or enhance magnetic properties like permeability, which is crucial for the performance of electric motors, generators, and transformers.

Making the Right Choice for Your Goal

The ideal heat treatment is dictated entirely by the final application of the component.

- If your primary focus is maximum hardness and wear resistance: You will use a hardening process like quenching, followed by a low-temperature temper to manage brittleness (for tools, dies, and bearings).

- If your primary focus is improving machinability or formability: You will use an annealing or normalizing process to soften the material and relieve internal stresses before manufacturing.

- If your primary focus is a balance of high strength and good toughness: You will use a carefully controlled quench and temper (Q&T) process to hit a specific target on the strength-toughness curve (for shafts, gears, and structural parts).

- If your primary focus is stabilizing parts after welding or heavy machining: You will use a post-weld heat treatment (PWHT) or stress-relieving cycle to prevent distortion and cracking.

Ultimately, understanding these property changes empowers you to specify not just a material, but a material condition perfectly suited to its purpose.

Summary Table:

| Property Altered | Goal of Heat Treatment | Common Processes |

|---|---|---|

| Hardness & Wear Resistance | Increase surface durability | Quenching |

| Strength (Tensile/Yield) | Increase load-bearing capacity | Hardening |

| Ductility & Formability | Improve shaping without cracking | Annealing |

| Toughness | Reduce brittleness, absorb impact | Tempering |

| Internal Stress | Prevent warping and cracking | Stress Relieving (PWHT) |

Ready to optimize your materials for peak performance? KINTEK specializes in precision lab equipment and consumables for heat treatment processes. Whether you're developing cutting tools, structural components, or specialized alloys, our solutions help you achieve the perfect balance of strength, hardness, and toughness. Contact our experts today to discuss how we can support your laboratory's material science needs.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How does a laboratory vacuum oven facilitate the gel content testing of UV-cured silicone rubber films?

- What are the applications of vacuum deposition? Create High-Performance Coatings for Your Products

- What is the rule of thumb for sintering temperature? Achieve the Perfect Balance for Your Materials

- What role does a high-temperature sintering furnace play in YSZ electrolyte preparation? Ensure Peak Densification

- What is a twin chamber furnace? Maximize Aluminum Melting Efficiency & Quality

- What is the difference between a batch furnace and a continuous casting furnace? Choose the Right Furnace for Your Production Line

- What role does a high-temperature furnace play in the homogenization of CuAlBe alloys? Optimize Shape Memory Performance

- Why is a vacuum oven required for anhydrous Zinc Phenylphosphate (ZnMPhP-A)? Achieve High Purity & Faster Dehydration