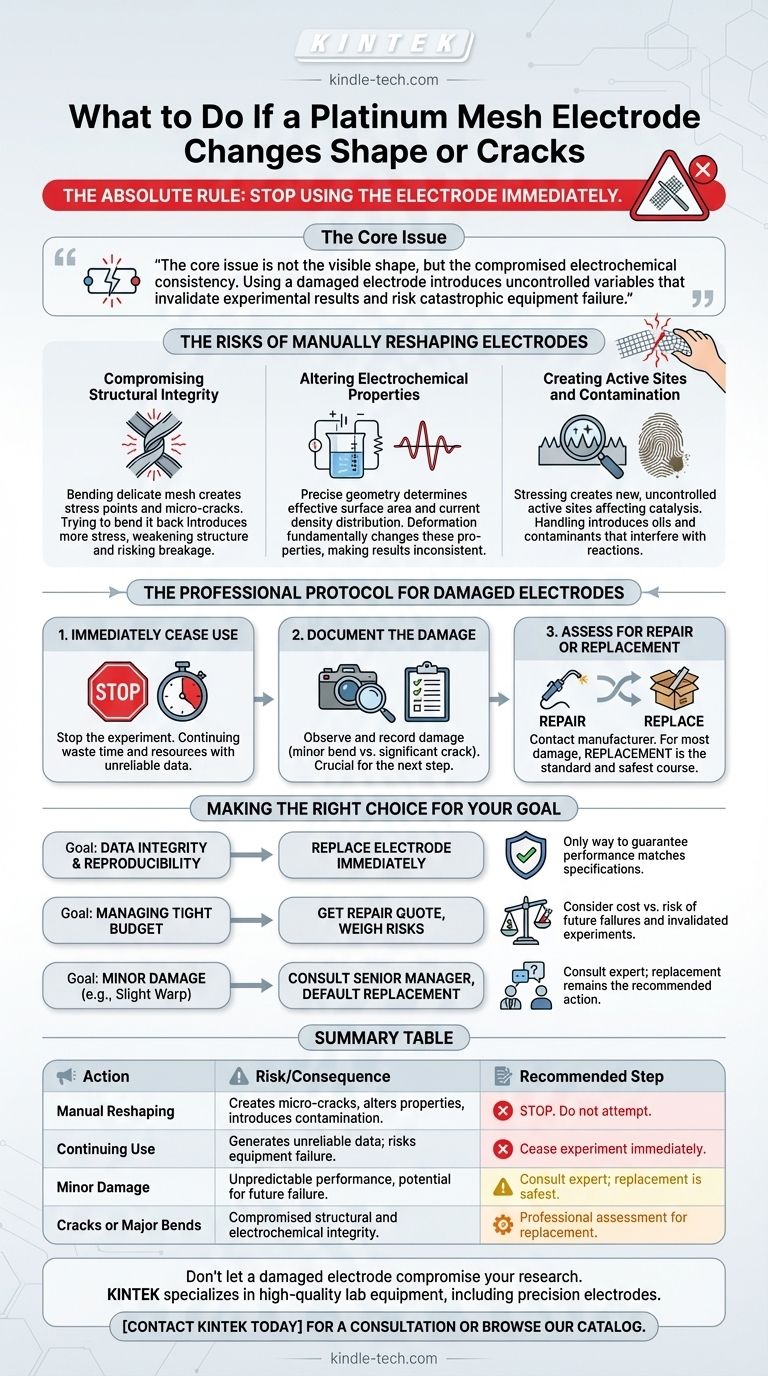

The absolute rule is to stop using the electrode immediately. It is strictly forbidden to manually alter its shape, as this will cause further mechanical damage. A damaged platinum electrode must be professionally repaired or, more commonly, replaced to ensure the integrity of your work.

The core issue is not the visible shape, but the compromised electrochemical consistency. Using a damaged electrode introduces uncontrolled variables that invalidate experimental results and risk catastrophic equipment failure.

The Risks of Manually Reshaping Electrodes

Attempting a "quick fix" by bending a platinum mesh electrode back into shape is a critical error. The reasons are rooted in material science and electrochemistry.

Compromising Structural Integrity

Platinum, while malleable, is not immune to work hardening and fatigue. Bending the delicate mesh wires, even once, creates stress points and micro-cracks.

Attempting to bend it back introduces even more stress, significantly weakening the structure and making it prone to breaking during an experiment.

Altering Electrochemical Properties

The precise geometry of an electrode determines its effective surface area and the distribution of current density across its face. These are critical parameters in any electrochemical measurement.

When you deform the mesh, you fundamentally and unpredictably change these properties, making your results inconsistent and impossible to reproduce.

Creating Active Sites and Contamination

Bending and stressing the metal can create new, highly reactive "active sites" on the platinum surface. This alters its catalytic behavior in an uncontrolled way.

Furthermore, handling the electrode introduces oils and contaminants that can be difficult to remove and will interfere with your reactions.

The Professional Protocol for Damaged Electrodes

When you discover a bent or cracked electrode, you must follow a clear protocol to protect your research and your equipment.

1. Immediately Cease Use

The first step is to stop the experiment. Continuing to use a compromised electrode will only generate unreliable data, wasting time and resources.

2. Document the Damage

Carefully observe and document the extent of the damage. Is it a minor bend in an outer region, or is it a significant crack near a weld point? This information will be crucial for the next step.

3. Assess for Repair or Replacement

Contact the manufacturer or a specialized laboratory equipment supplier. They can advise whether a professional repair (such as annealing or micro-welding) is feasible or cost-effective.

For most minor to moderate damage, especially cracks, replacement is the standard and safest course of action. The risk of a faulty repair compromising future experiments is often too high.

Making the Right Choice for Your Goal

Your decision to repair or replace should be guided by the demands of your work.

- If your primary focus is data integrity and reproducibility: Replace the electrode immediately. This is the only way to guarantee that the electrode's performance matches its specifications.

- If your primary focus is managing a tight budget: Contact the manufacturer for a professional repair quote, but weigh that cost against the risk of future failures and invalidated experiments.

- If the damage appears extremely minor (e.g., a slight warp): Consult a senior lab manager or principal investigator before reuse. The default and recommended action remains replacement.

Ultimately, treating your electrode with care and replacing it when damaged is a fundamental investment in the quality of your results.

Summary Table:

| Action | Risk/Consequence | Recommended Step |

|---|---|---|

| Manual Reshaping | Creates micro-cracks, alters electrochemical properties, introduces contamination. | STOP. Do not attempt. |

| Continuing Use | Generates unreliable, unreproducible data; risks equipment failure. | Cease experiment immediately. |

| Minor Damage | Unpredictable performance, potential for future failure. | Consult expert; replacement is safest. |

| Cracks or Major Bends | Compromised structural and electrochemical integrity. | Professional assessment for replacement. |

Don't let a damaged electrode compromise your research. A faulty platinum electrode introduces uncontrolled variables that can invalidate your results and damage sensitive equipment. For laboratories where data integrity and reproducibility are paramount, using a properly specified and undamaged electrode is non-negotiable.

KINTEK specializes in high-quality lab equipment and consumables, including precision electrodes. Our experts can help you select the right replacement to ensure your electrochemical experiments proceed with accuracy and reliability.

Contact KINTEK today for a consultation on electrode replacement or to browse our catalog of reliable lab supplies.

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Auxiliary Electrode for Laboratory Use

- Gold Disc Electrode

- Gold Electrochemical Sheet Electrode Gold Electrode

People Also Ask

- How should a platinum sheet electrode be operated during an experiment? Ensure Accurate and Reproducible Results

- What are the available specifications for platinum sheet electrodes? Find the Perfect Fit for Your Electrochemical Needs

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance

- What precautions should be taken when using a platinum sheet electrode? Ensure Accurate & Reproducible Electrochemical Data

- What is the proper post-treatment procedure for a platinum sheet electrode? Ensure Long-Term Accuracy & Protect Your Investment