To properly clean a mortar and pestle for KBr pellet preparation, you must use a highly volatile organic solvent like acetone. The goal is to rigorously remove any organic residues or moisture that could interfere with the infrared (IR) spectrum of your sample, ensuring the data you collect is accurate and free from contamination.

The core objective is not merely to clean the mortar, but to render it spectroscopically invisible. This requires a multi-step process that eliminates any substance, including the cleaning agent itself, that could absorb infrared radiation and obscure your sample's true signal.

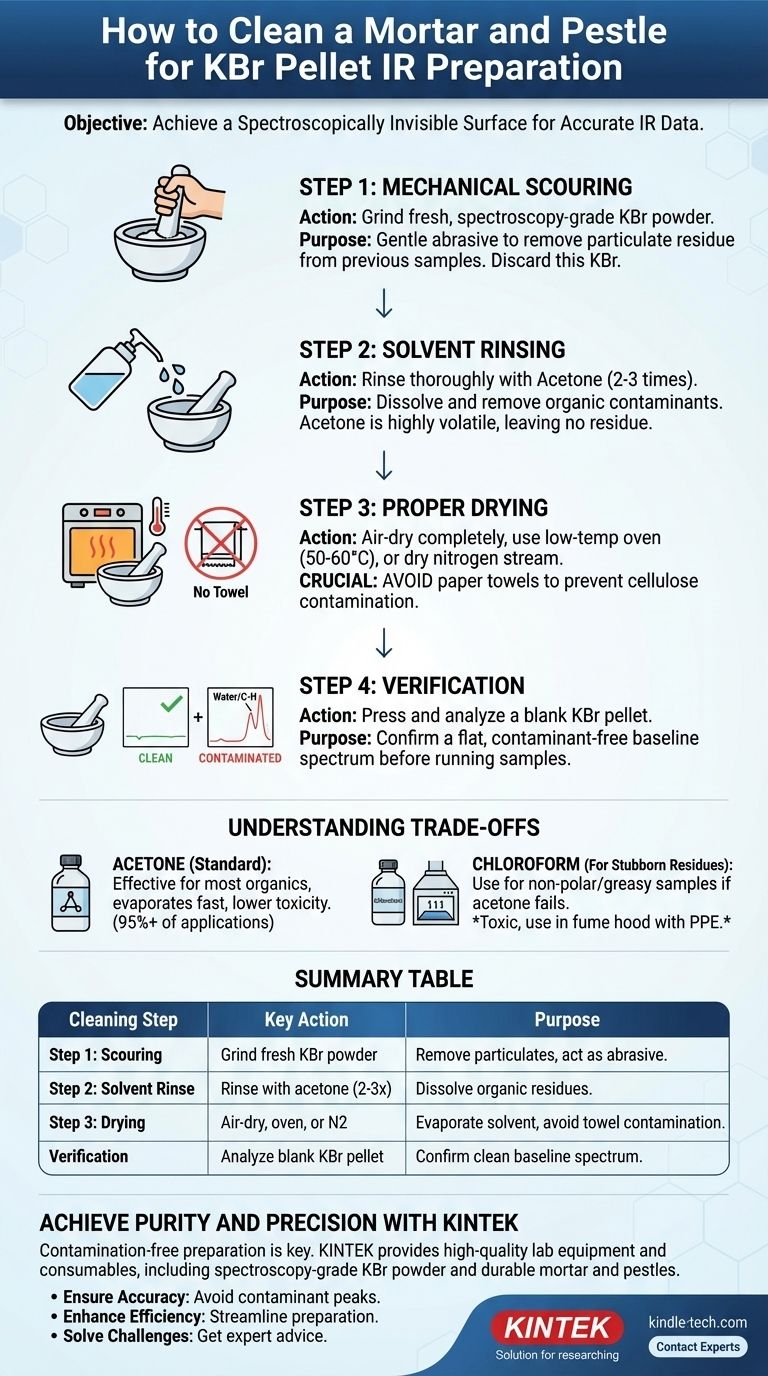

Why Meticulous Cleaning is Non-Negotiable

Infrared spectroscopy is an incredibly sensitive technique capable of detecting minute quantities of material. This sensitivity is a double-edged sword; any contaminant left in the mortar and pestle from a previous analysis, handling, or the cleaning process itself can easily appear in your final spectrum.

The Problem of Contamination

Even trace amounts of oils from your fingers, residue from a prior sample, or absorbed atmospheric water will produce distinct peaks in an IR spectrum. These contaminant peaks can overlap with your sample's peaks, leading to misinterpretation of the data or completely masking the signals you are trying to measure.

The Properties of an Ideal Solvent

A suitable cleaning solvent for IR preparation must have two key properties. First, it must effectively dissolve a wide range of organic compounds. Second, it must be highly volatile, meaning it evaporates completely and rapidly, leaving absolutely no residue behind. Acetone is the standard choice because it excels in both areas.

The Definitive Cleaning Protocol

A simple wipe-down is insufficient. Follow this procedure to ensure your equipment is truly ready for analysis.

Step 1: Mechanical Scouring

Before using any solvent, perform a physical cleaning step. Grind a small amount of fresh, spectroscopy-grade KBr powder in the mortar. This acts as a gentle abrasive, scouring away any residual particulate matter from the previous sample that may be lodged in the mortar's microscopic pores. Discard this KBr.

Step 2: Solvent Rinsing

Rinse the mortar and pestle thoroughly with acetone. Use a squirt bottle to wash the surfaces, ensuring you cover the entire grinding area and the pestle tip. It is best practice to perform this rinse two or three times to ensure all soluble contaminants are removed.

Step 3: Proper Drying (Crucial)

This is the most common point of failure. Do not use a paper towel or lab tissue to dry the equipment. These materials are made of cellulose, which has a very strong and characteristic IR absorbance that will contaminate your pellet.

Instead, allow the mortar and pestle to air-dry completely. For faster results, you can place them in a low-temperature oven (e.g., 50-60 °C) for a few minutes or use a gentle stream of dry nitrogen gas.

Understanding the Trade-offs

While acetone is the primary choice, other solvents can be used in specific situations.

Acetone: The Standard Choice

Acetone is effective for most common organic residues, evaporates extremely quickly, and is relatively low in toxicity compared to other options. For over 95% of applications, it is the correct and sufficient choice.

Chloroform: For Stubborn Residues

In cases of heavy contamination from non-polar, greasy, or polymeric samples, chloroform can be a more effective solvent. However, it is more toxic and requires handling in a fume hood with appropriate personal protective equipment. It should only be considered if acetone fails to produce a clean background.

How to Verify Your Cleaning

The ultimate test of your cleaning procedure is to press a "blank" pellet. This is a pellet made using only the KBr powder from your stock bottle.

Run an IR spectrum of this blank KBr pellet. The resulting spectrum should be a flat line with minimal absorbance peaks. If you see significant peaks for water (a broad signal around 3400 cm⁻¹) or C-H bonds (around 2900 cm⁻¹), your cleaning and drying process was insufficient.

- If your primary focus is routine analysis: A thorough acetone rinse followed by air or oven drying is a reliable and efficient protocol.

- If your primary focus is trace analysis or a weak sample: Always run a blank KBr pellet first to confirm a clean background before committing your valuable sample.

- If you suspect contamination from a non-polar sample: Use acetone first, and only proceed to a chloroform rinse if the blank spectrum still shows contamination.

A pristine spectrum begins with a pristine preparation.

Summary Table:

| Cleaning Step | Key Action | Purpose |

|---|---|---|

| Step 1: Scouring | Grind fresh KBr powder | Remove particulate matter and act as an abrasive. |

| Step 2: Solvent Rinse | Rinse thoroughly with acetone (2-3 times) | Dissolve and remove organic residues. |

| Step 3: Drying | Air-dry or use low-temperature oven/dry nitrogen | Evaporate solvent completely; avoid contamination from towels. |

| Verification | Press and analyze a blank KBr pellet | Confirm a clean, flat baseline in the IR spectrum. |

Achieve Purity and Precision in Your Lab

Contamination-free sample preparation is the foundation of reliable IR spectroscopy data. KINTEK specializes in providing high-quality lab equipment and consumables, including spectroscopy-grade KBr powder and durable mortar and pestle sets, designed to meet the stringent demands of analytical laboratories.

Let our expertise support your research:

- Ensure Accuracy: Use our recommended materials to avoid contaminant peaks in your spectra.

- Enhance Efficiency: Streamline your preparation process with reliable, consistent products.

- Solve Challenges: Get personalized advice for trace analysis or stubborn contamination issues.

Ready to optimize your IR sample preparation? Contact our experts today via our Contact Form to discuss your specific laboratory needs and discover how KINTEK can help you achieve superior results.

Visual Guide

Related Products

- Laboratory Jaw Crusher

- Laboratory Test Sieves and Sieving Machines

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Small Injection Molding Machine for Lab Use

People Also Ask

- How does a jaw crusher contribute to the primary processing of slate waste? Optimize Your Size Reduction Workflow

- What is the primary role of grinding equipment in the pretreatment of copper concentrate for bioleaching?

- What is the function of laboratory crushing and sieving systems in biomass pretreatment? Optimize Your Lab Results

- What is the primary function of an industrial jaw crusher in recycled aggregate concrete? Boost Efficiency & Quality

- Why use a laboratory crushing and sieving system for rice husks? Optimize Hydrolysis for 1mm Particle Size