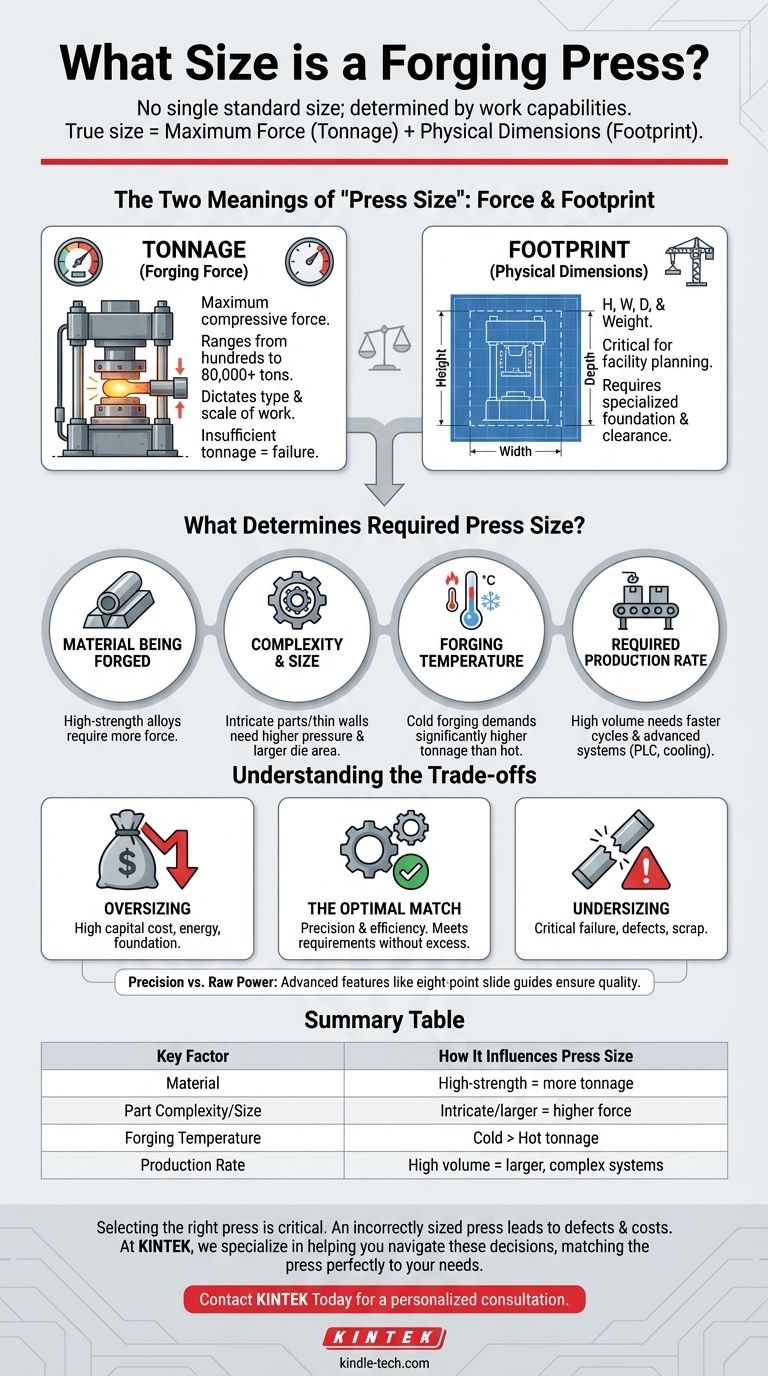

A forging press has no single standard size; its dimensions are entirely dictated by the work it is designed to perform. The most critical measure of a press's "size" is its tonnage—the amount of force it can exert—which can range from a few hundred tons for small components to over 80,000 tons for massive aerospace and industrial parts. Physical footprint is the second, equally important measure, determining the space and foundation required for the machine.

A forging press is not defined by a single size but by its capabilities. Its true "size" is a combination of its maximum force (tonnage) and physical dimensions, both of which are determined by the material, complexity, and scale of the parts it is engineered to produce.

The Two Meanings of "Press Size": Force and Footprint

To understand the size of a forging press, you must consider two separate but related metrics. The one you prioritize depends entirely on your objective, whether you are designing a part, planning a facility, or sourcing a machine.

Defining Size by Tonnage (Forging Force)

Tonnage is the most common and important metric for a forging press. It refers to the maximum compressive force the press can apply to a workpiece.

This force dictates the type and scale of work the press can handle. A press with insufficient tonnage will fail to properly shape the material, resulting in defects or an incomplete part.

Defining Size by Physical Dimensions

The physical footprint—its height, width, depth, and weight—is the second component of its size. These dimensions are critical for facility planning.

A massive press requires a specially engineered foundation, significant overhead clearance for operation and maintenance, and a large surrounding area for staging materials and handling finished parts.

What Determines the Required Press Size?

The necessary tonnage and physical dimensions of a press are not arbitrary. They are a direct result of several key engineering factors that must be carefully calculated before a forging process is designed.

Material Being Forged

Different materials have different levels of resistance to deformation. Forging high-strength superalloys like Inconel or titanium requires substantially more force than forging aluminum or carbon steel at the same temperature.

Complexity and Size of the Part

Larger parts naturally require more force and a larger die area. Similarly, parts with intricate details, thin walls, or complex geometries demand higher pressures to ensure the material flows into every part of the die cavity.

Forging Temperature (Hot vs. Cold)

Hot forging is performed above a material's recrystallization temperature, making it more malleable and requiring less force. Cold forging, by contrast, is done at or near room temperature. It demands significantly higher tonnage but yields parts with excellent surface finish and dimensional accuracy.

Required Production Rate

High-volume production lines require presses that can cycle quickly and reliably. These machines often incorporate sophisticated systems like PLC controls and water-cooled heat exchangers to manage thermal stress and maintain consistent quality, which can add to the machine's overall complexity and size.

Understanding the Trade-offs

Selecting a press is a balancing act. The ideal choice is a machine that meets all technical requirements without being excessively oversized, which introduces unnecessary costs and inefficiencies.

The Cost of Oversizing

A press that is too large for the job incurs significant penalties. These include a higher initial capital investment, more extensive and costly foundation work, and higher energy consumption for every part produced.

The Limitations of Undersizing

An undersized press is a critical failure. If the tonnage is insufficient, the press cannot fully form the part, leading to scrap. If its physical dimensions are too small, the die required for the part simply won't fit.

Precision vs. Raw Power

Immense force is useless without control. Modern presses use features like eight-point slide guides to ensure the moving platen remains perfectly parallel under extreme loads. This precision is what guarantees part quality and consistency, proving that sophisticated engineering is just as important as raw tonnage.

Making the Right Choice for Your Goal

Your primary objective determines which aspect of "size" is most important to you.

- If your primary focus is part design: Prioritize calculating the required tonnage based on your material, part geometry, and forging temperature.

- If your primary focus is manufacturing engineering: Match the required tonnage and die dimensions with available press specifications, considering cycle time and precision.

- If your primary focus is facility planning: Focus on the press's physical footprint, weight, and power requirements to ensure your infrastructure can support it.

Ultimately, selecting the right press size is about perfectly matching the machine's capabilities to the specific demands of the component you intend to create.

Summary Table:

| Key Factor | How It Influences Press Size |

|---|---|

| Material | High-strength alloys (e.g., titanium) require significantly more tonnage than aluminum or steel. |

| Part Complexity/Size | Intricate geometries and larger parts demand higher force and a larger die area. |

| Forging Temperature | Cold forging requires much higher tonnage than hot forging for the same part. |

| Production Rate | High-volume lines need larger, more complex presses with advanced controls and cooling systems. |

Selecting the right forging press is critical to your project's success and efficiency. An incorrectly sized press can lead to part defects, excessive scrap, and higher operational costs.

At KINTEK, we specialize in helping you navigate these critical decisions. Our expertise in lab and industrial equipment ensures you get a press perfectly matched to your material, part design, and production goals—avoiding the pitfalls of oversizing or undersizing.

Let our experts guide you to the optimal solution. Contact KINTEK today for a personalized consultation and discover the perfect press for your specific forging challenges.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the function of a laboratory hydraulic press in alumina preparation? Optimize Heat Transfer and Sample Stability

- What are the preventive maintenance of hydraulic press machine? Maximize Uptime and Prevent Costly Failures

- Why does the pressing of Zr2Al-GNS green bodies require 400 MPa? Achieving High-Density Material Stability

- What is the difference between a power press and a hydraulic press? Choose the Right Force for Your Application

- What is considered high pressure for hydraulics? A Guide to Modern System Ranges

- What is uniaxial pressing of ceramics? A Guide to High-Volume Production of Simple Shapes

- What is the role of a laboratory hydraulic press in the preparation of LiTa2PO8 (LTPO) ceramic pellets? | KINTEK

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?