When preparing a sample for XRF analysis, the ideal "size" is not a single universal dimension. The critical factors are the sample's form, its surface quality, and its thickness relative to the X-ray beam, as these directly impact the accuracy and reliability of your results.

The core principle of XRF sample preparation is not to meet a specific weight or volume, but to create a sample that is perfectly flat, homogeneous, and "infinitely thick" to the X-ray beam, ensuring the measurement is consistent and representative.

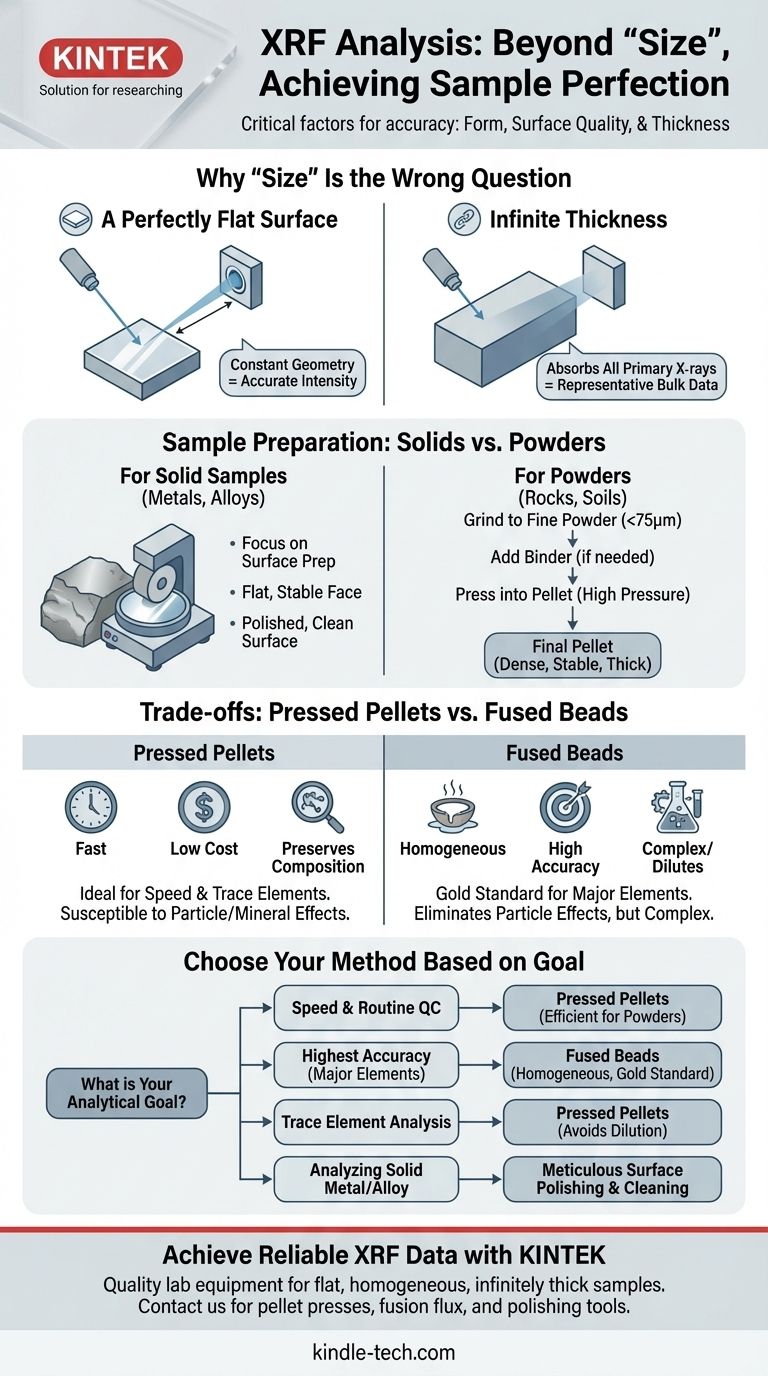

Why "Size" Is the Wrong Question

Users often ask for a specific sample size, but in XRF, the geometry and uniformity of the sample are far more important than its overall mass or volume. Two key principles govern an effective sample.

The Importance of a Flat, Uniform Surface

An XRF spectrometer is calibrated for a precise distance between the X-ray source, the sample, and the detector.

Any irregularities on the sample surface—such as bumps or pits—change this distance. This variation alters the intensity of the X-rays detected, introducing significant analytical error. A perfectly flat surface ensures this geometry remains constant across the entire analysis area.

The Concept of "Infinite Thickness"

The sample must be thick enough that the primary X-ray beam cannot pass through it. If the beam penetrates the sample completely, the results will not be representative of the bulk material.

When the sample is sufficiently thick to absorb all primary X-rays, it is considered infinitely thick. This is a critical condition for quantitative analysis, and the required thickness varies depending on the material's density and the energy of the X-rays.

Sample Preparation Based on Material Type

The ideal preparation method depends entirely on whether your sample is a solid piece of material or a powder, such as a rock, soil, or chemical.

For Solid Samples: Surface Is Everything

If you are analyzing a solid piece of metal, alloy, or polymer, the focus is entirely on surface preparation.

The sample must be large enough to present a stable, flat face to the instrument. The surface should be ground or polished to a smooth, mirror-like finish. It must also be thoroughly cleaned to remove any surface contamination.

For Powders: Creating the Perfect Pressed Pellet

The most common method for powders is to create a pressed pellet. This involves grinding the sample and pressing it under high pressure into a small, solid disc.

Key factors for a high-quality pellet include:

- Particle Size: The sample must be ground to a fine, uniform powder, typically smaller than 75 micrometers, to minimize analytical errors caused by inconsistent particle size.

- Binder: If the powder does not cohere on its own, a wax binder is added to help form a durable pellet.

- Pressure: Applying sufficient pressure ensures a dense, stable pellet that will not crumble.

- Thickness: The final pellet must be thick enough to achieve "infinite thickness" for the elements being analyzed.

Understanding the Trade-offs

For powders, the main alternative to a pressed pellet is a fused bead. Each method has distinct advantages and disadvantages.

The Case for Pressed Pellets

Pressed pellets are fast, low-cost, and preserve the original sample composition, making them ideal for analyzing trace elements.

However, they can be susceptible to errors from particle size effects and mineralogical variations, which can affect the accuracy for major elements.

The Case for Fused Beads

Creating a fused bead involves mixing the sample with a chemical flux (like a lithium borate) and heating it in a crucible until it melts into a homogenous glass disc.

This process eliminates all particle size and mineralogical effects, yielding superior accuracy for major elements. The downside is that it is more complex, time-consuming, and dilutes the sample, which can make it difficult to measure trace elements.

How to Prepare Your Sample for Your Goal

Your analytical goal should dictate your preparation method.

- If your primary focus is speed and routine QC: Pressed pellets are the most efficient choice for analyzing powders, providing good results with minimal effort.

- If your primary focus is the highest possible accuracy for major elements: Fused beads are the gold standard, as they create a perfectly homogeneous sample.

- If your primary focus is analyzing trace elements: Use a pressed pellet to avoid the dilution effect inherent in the fusion method.

- If your primary focus is analyzing a solid metal or alloy: Meticulous surface polishing and cleaning are non-negotiable for accurate results.

Ultimately, a well-prepared sample is the foundation of any reliable XRF analysis.

Summary Table:

| Sample Type | Key Preparation Focus | Best For |

|---|---|---|

| Solid (Metal, Alloy) | Surface Polishing & Cleaning | Bulk Analysis |

| Powder (Soil, Rock) | Pressed Pellet or Fused Bead | Major/Trace Elements |

| Pressed Pellet | Fine Grinding, Binder, High Pressure | Speed, Trace Elements |

| Fused Bead | Flux Mixing, Melting to Glass Disc | High Accuracy for Major Elements |

Struggling with inconsistent XRF results? The right lab equipment is key to perfect sample preparation. KINTEK specializes in high-quality lab equipment and consumables for XRF analysis, including pellet presses, fusion flux, and polishing tools. Our products help you achieve flat, homogeneous, and infinitely thick samples for reliable data. Contact us today (#ContactForm) to discuss your lab's needs and enhance your analytical accuracy!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the function of a laboratory hydraulic press for Li10GeP2S12 pellets? Optimize Solid-State Battery Performance

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis