In a modern laboratory, vacuum pumps are categorized primarily by whether they use oil or operate "dry." The most common types are oil-sealed rotary vane pumps for high-vacuum needs and oil-free diaphragm or scroll pumps for applications where sample purity is critical. Your choice depends directly on the vacuum level required and your tolerance for potential oil contamination.

The central decision when selecting a lab vacuum pump is not just about the technology, but about a fundamental trade-off: choosing between the high vacuum performance of an oil-sealed pump and the absolute cleanliness of an oil-free (dry) pump.

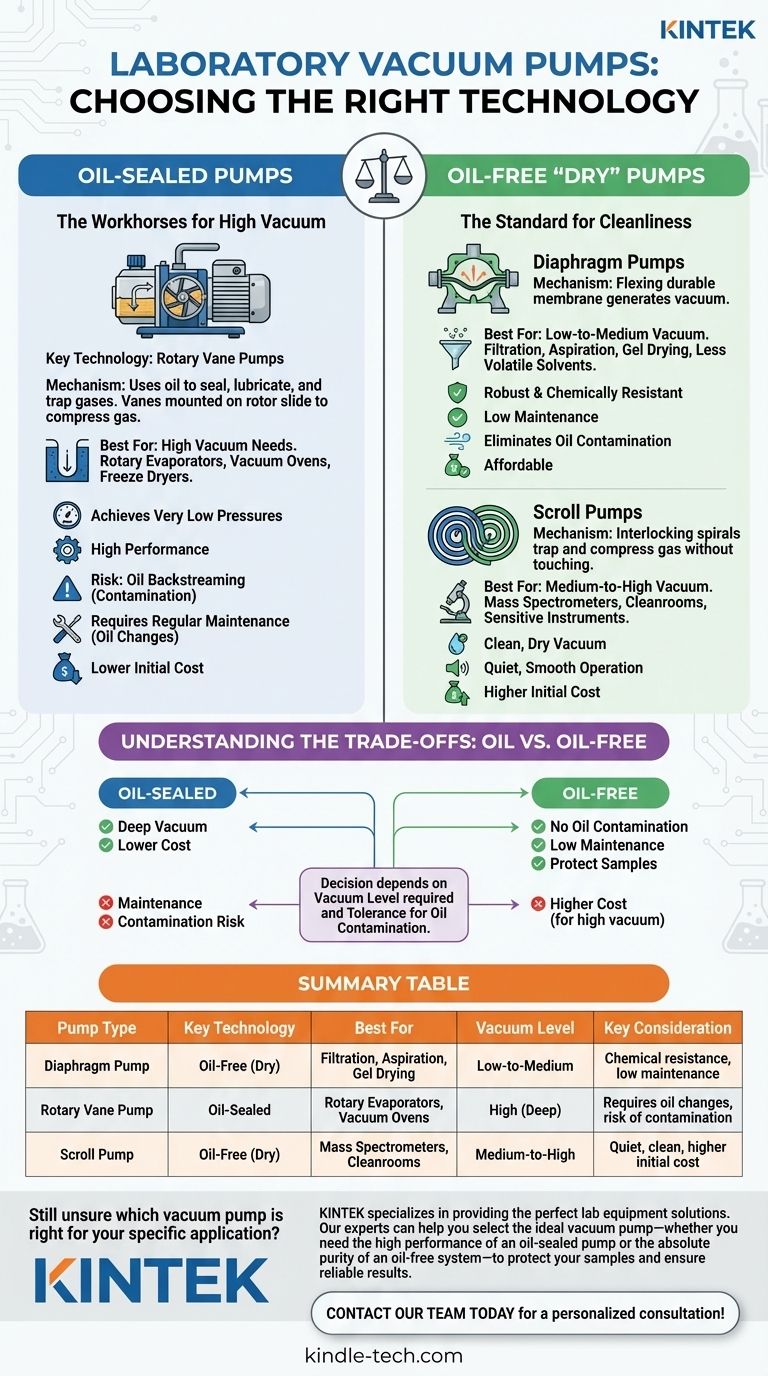

The Two Fundamental Categories of Lab Pumps

At the highest level, laboratory vacuum pumps are divided into two distinct families. This division is the most critical factor in determining where and how a pump can be used.

Oil-Sealed Pumps: The Workhorses for High Vacuum

Oil-sealed pumps, most commonly rotary vane pumps, are the traditional standard for applications requiring a medium to high vacuum. They use oil to create a seal, lubricate moving parts, and help trap pumped gas molecules.

These pumps are known for their ability to achieve very low pressures, making them essential for demanding tasks like operating a mass spectrometer or a high-performance vacuum oven.

Oil-Free "Dry" Pumps: The Standard for Cleanliness

Oil-free, or "dry," pumps have become increasingly prevalent because they completely eliminate the risk of oil vapor contaminating a sample. This is non-negotiable in sensitive analytical or biological work.

These pumps use alternative mechanical principles that require no oil for sealing or lubrication. The most common types are diaphragm, scroll, and piston pumps.

A Deeper Look at Common Pump Technologies

While the oil-sealed versus oil-free distinction is paramount, understanding the specific technology helps you match a pump to your exact task.

Diaphragm Pumps

A diaphragm pump generates a vacuum by flexing a durable, chemically resistant membrane. This simple, robust mechanism makes them a staple for general lab work.

They provide a low-to-medium vacuum, which is perfect for tasks like filtration, aspiration (removing liquids), gel drying, and use with rotary evaporators for less volatile solvents.

Rotary Vane Pumps

A rotary vane pump uses a set of vanes mounted on an off-center rotor. As the rotor turns, the vanes slide in and out, trapping and compressing gas from the inlet to the outlet.

The entire mechanism is immersed in oil, allowing these pumps to achieve the high vacuum levels needed for rotary evaporators, vacuum ovens, and freeze dryers.

Scroll Pumps

A scroll pump uses two interlocking, spiral-shaped scrolls to pump gas. One scroll is fixed while the other orbits it, trapping and compressing pockets of gas toward the center outlet.

Because the scrolls never touch, they require no lubrication. This design provides a clean, dry vacuum that is deeper than a diaphragm pump, making it ideal for cleanroom environments and sensitive instruments like mass spectrometers. They are also known for their quiet, smooth operation.

Understanding the Trade-offs: Oil vs. Oil-Free

Choosing the right pump requires an objective look at the benefits and drawbacks of each approach.

The Case for Oil-Sealed Pumps

The primary advantage of an oil-sealed rotary vane pump is its ability to pull a deep vacuum at a relatively lower initial cost compared to a high-performance dry pump.

However, they come with significant downsides. They require regular maintenance, including oil changes and proper disposal of contaminated oil. Most importantly, they carry the inherent risk of oil backstreaming, where oil vapor moves from the pump into your vacuum system, potentially ruining sensitive samples.

The Case for Oil-Free Pumps

The definitive advantage of a dry pump is eliminating oil contamination. This protects your experiments, requires far less routine maintenance, and removes the need to handle waste oil.

The main trade-off is often a higher upfront cost. While a diaphragm pump is sufficient and affordable for many tasks, a dry scroll pump capable of high vacuum performance will be more expensive than its oil-sealed equivalent.

Making the Right Choice for Your Application

Selecting the correct pump is about aligning the technology with your scientific goal.

- If your primary focus is simple filtration, aspiration, or gel drying: A rugged and affordable oil-free diaphragm pump is almost always the best choice.

- If your primary focus is deep vacuum for a rotary evaporator or vacuum oven: A rotary vane pump is the traditional workhorse, but a dry scroll pump is a superior (though more expensive) option if sample purity is a concern.

- If your primary focus is running a highly sensitive instrument like a mass spectrometer: An oil-free scroll pump is the modern standard to guarantee a clean, interference-free vacuum.

Ultimately, understanding the core principles of each pump empowers you to protect your samples and achieve reliable results.

Summary Table:

| Pump Type | Key Technology | Best For | Vacuum Level | Key Consideration |

|---|---|---|---|---|

| Diaphragm Pump | Oil-Free (Dry) | Filtration, Aspiration, Gel Drying | Low-to-Medium | Chemical resistance, low maintenance |

| Rotary Vane Pump | Oil-Sealed | Rotary Evaporators, Vacuum Ovens | High (Deep) | Requires oil changes, risk of contamination |

| Scroll Pump | Oil-Free (Dry) | Mass Spectrometers, Cleanrooms | Medium-to-High | Quiet, clean, higher initial cost |

Still unsure which vacuum pump is right for your specific application?

KINTEK specializes in providing the perfect lab equipment solutions. Our experts can help you select the ideal vacuum pump—whether you need the high performance of an oil-sealed pump or the absolute purity of an oil-free system—to protect your samples and ensure reliable results.

Contact our team today for a personalized consultation! Let us help you enhance your lab's efficiency and precision with the right equipment from KINTEK, your trusted partner for laboratory needs.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Variable Speed Peristaltic Pump

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- Why are zirconia grinding jars and balls preferred for sulfide electrolytes? Ensure Purity & Battery Performance

- What is the technical significance of selecting hardened stainless steel grinding balls? Optimize Energy and Purity

- What is the thermal shock of quartz tube? Withstand Extreme Temperature Changes Instantly

- What is the lining material for furnace? A Guide to High-Temperature Refractories

- Why are alumina grinding balls selected for nanostructured eutectic steel? Ensure Purity and Precision

- Why are zirconia (ZrO2) grinding balls and jars preferred for Ni-Co-Al milling? Ensure Pure Alloy Performance

- Why are polyurethane milling jars and corundum balls used for boron carbide? Ensure Purity in Advanced Ceramic Mixing

- What role does a Quartz Fiber Filter play in a continuous flow catalytic reactor? Enhance Bed Stability & Flow