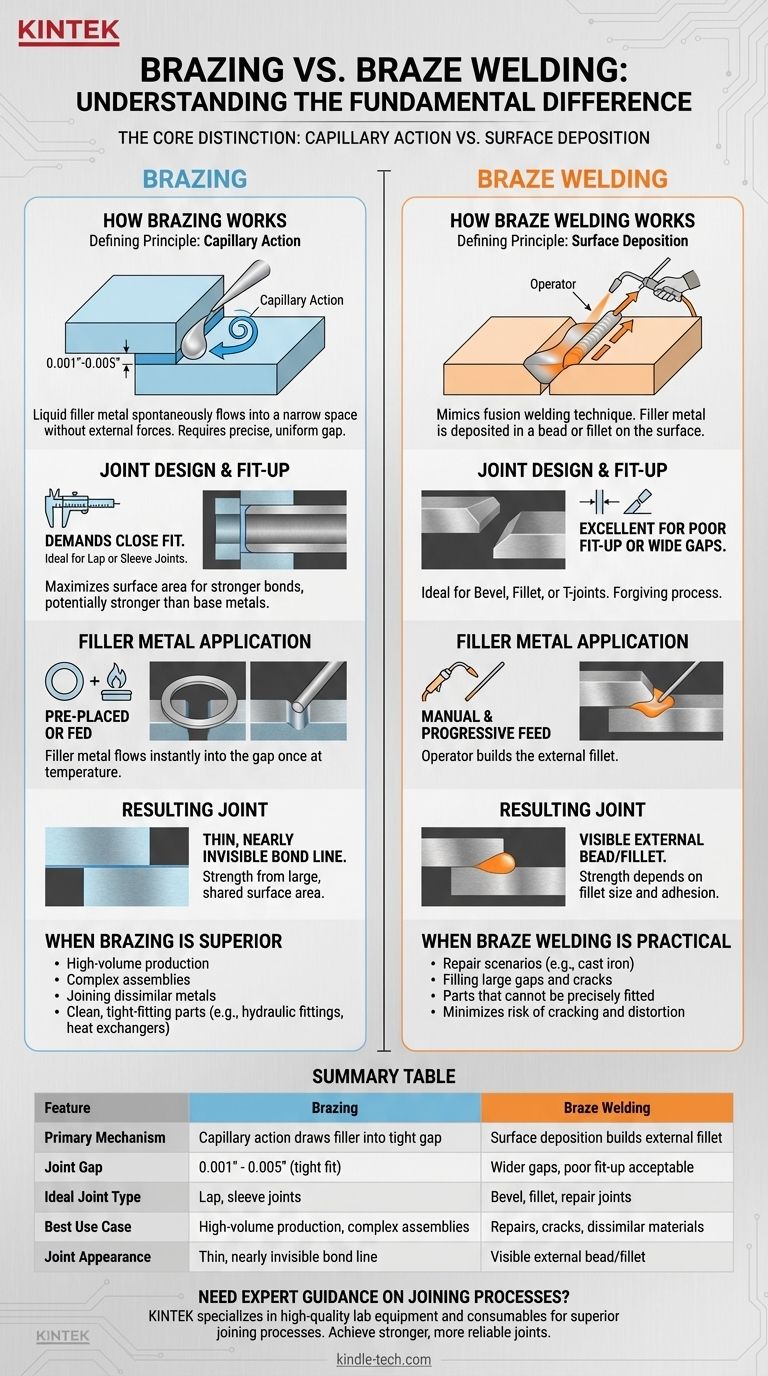

At a fundamental level, the difference lies in how the filler metal joins the parts. True brazing uses capillary action to draw molten filler metal into a very tight, clean gap between two components. In contrast, braze welding deposits filler metal in a bead or fillet on the surface of a joint, much like conventional welding, but without melting the base metals.

The core distinction is simple: brazing pulls filler metal into a joint, while braze welding lays filler metal onto a joint. This single difference in application dictates everything from joint design to the appropriate use case for each process.

The Defining Principle: Capillary Action vs. Surface Deposition

To truly grasp the difference, you must understand the physical mechanism at work in each process. They are fundamentally distinct despite both using a filler metal that melts at a lower temperature than the base metals.

How Brazing Works

Brazing is defined by capillary action. This is the phenomenon where a liquid spontaneously flows into a narrow space without assistance from, or even in opposition to, external forces like gravity.

For this to occur, the joint must be designed with a very specific, uniform gap—typically between 0.001" and 0.005". The filler metal is then introduced at the edge of this joint, where it melts and is instantly pulled into the gap, creating a complete, high-strength bond across the entire surface.

How Braze Welding Works

Braze welding does not use capillary action. Instead, the technique mimics traditional fusion welding (like TIG or Oxy-acetylene welding).

A heat source is used to create a molten puddle of filler metal on the surface of the base metals. The operator then manually adds more filler rod to this puddle to build up a bead, or fillet, along the seam. It is used to fill V-grooves, butt joints, or T-joints where there is no tight gap for capillary action to work.

Comparing the Processes Head-to-Head

The practical differences in joint preparation and application stem directly from the presence or absence of capillary action.

Joint Design and Fit-Up

Brazing demands a close-fitting joint. Lap or sleeve joints are ideal because they maximize the surface area for the filler metal to bond, resulting in a joint that can be stronger than the base metals themselves.

Braze welding, on the other hand, is excellent for joints with poor fit-up or wide gaps. It's often used for bevel and fillet joints, similar to those prepared for arc welding.

Filler Metal Application

In brazing, filler metal can be pre-placed as a ring or shim within the assembly before heating. Alternatively, it can be touched to the joint line once the assembly is at temperature, allowing it to flow instantly into the gap.

In braze welding, the filler rod is manually and progressively fed into the heat source along the joint line to build the external fillet.

Resulting Joint Strength and Appearance

A properly brazed joint has a very thin, almost invisible bond line. Its strength is derived from the large, shared surface area of the two parts being joined.

A braze welded joint has a visible external bead, similar in appearance to a welded joint. Its strength is dependent on the size of the fillet and its adhesion to the base metal surfaces.

Understanding the Trade-offs

The term "braze welding" is a source of constant confusion. It's named for its application technique (resembling welding) but its underlying physics (no base metal melting) makes it a brazing-family process.

When Brazing is the Superior Choice

Brazing is ideal for high-volume production, complex assemblies, and joining dissimilar metals. Its ability to join entire surfaces in clean, tight-fitting parts makes it perfect for manufacturing hydraulic fittings, heat exchangers, and aerospace components.

When Braze Welding is More Practical

Braze welding excels in repair scenarios, especially on materials sensitive to high heat, like cast iron. Its ability to fill large gaps and cracks without melting the base metal minimizes the risk of cracking and distortion. It is a forgiving process for joining parts that cannot be precisely fitted.

The Key Limitation

The primary limitation of both processes compared to fusion welding is temperature service. Because the filler metals have lower melting points, brazed and braze welded joints are not suitable for high-temperature applications where they might re-melt.

Making the Right Choice for Your Application

The best method is determined by your joint configuration, material, and final goal.

- If your primary focus is joining tightly fitted parts with maximum shear strength: Choose traditional brazing, as capillary action ensures complete and uniform joint penetration.

- If your primary focus is repairing a crack or joining parts with a poor fit-up: Choose braze welding to effectively build up material and bridge the gap.

- If your primary focus is joining thin sheet metal at an edge: Braze welding can create a strong fillet, while brazing would require an overlapping joint design.

- If your primary focus is creating a strong, leak-proof seal in tubing or pipe fittings: Brazing is the industry standard due to its ability to fully penetrate a sleeve joint.

Ultimately, knowing whether your task requires filling a tight gap or building an external fillet will always guide you to the correct process.

Summary Table:

| Feature | Brazing | Braze Welding |

|---|---|---|

| Primary Mechanism | Capillary action draws filler into tight gap | Surface deposition builds external fillet |

| Joint Gap | 0.001" - 0.005" (tight fit) | Wider gaps, poor fit-up acceptable |

| Ideal Joint Type | Lap, sleeve joints | Bevel, fillet, repair joints |

| Best Use Case | High-volume production, complex assemblies | Repairs, cracks, dissimilar materials |

| Joint Appearance | Thin, nearly invisible bond line | Visible external bead/fillet |

Need Expert Guidance on Joining Processes?

Whether you're working with complex assemblies requiring precise brazing or tackling challenging repairs with braze welding, having the right equipment and consumables is crucial for success.

KINTEK specializes in high-quality lab equipment and consumables that support superior joining processes. Our products help ensure consistent heat application, proper filler metal flow, and reliable results for laboratories and manufacturing facilities.

Let us help you achieve stronger, more reliable joints.

Contact our experts today to discuss your specific application needs and discover how KINTEK's solutions can enhance your joining capabilities.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication