The best lab-grown diamond process is not a single method, but rather the one that produces the highest quality diamond for a given price, regardless of origin. While several methods exist, the two dominant commercial processes for gem-quality diamonds are High Pressure/High Temperature (HPHT) and Chemical Vapor Deposition (CVD). Each creates a real diamond with distinct characteristics, but neither is inherently superior to the other.

The central takeaway is that the growth method (HPHT vs. CVD) is less important than the final result. Your focus should be on the diamond's official grade—its 4 Cs (Cut, Color, Clarity, Carat)—as documented in its certification, not on how it was made.

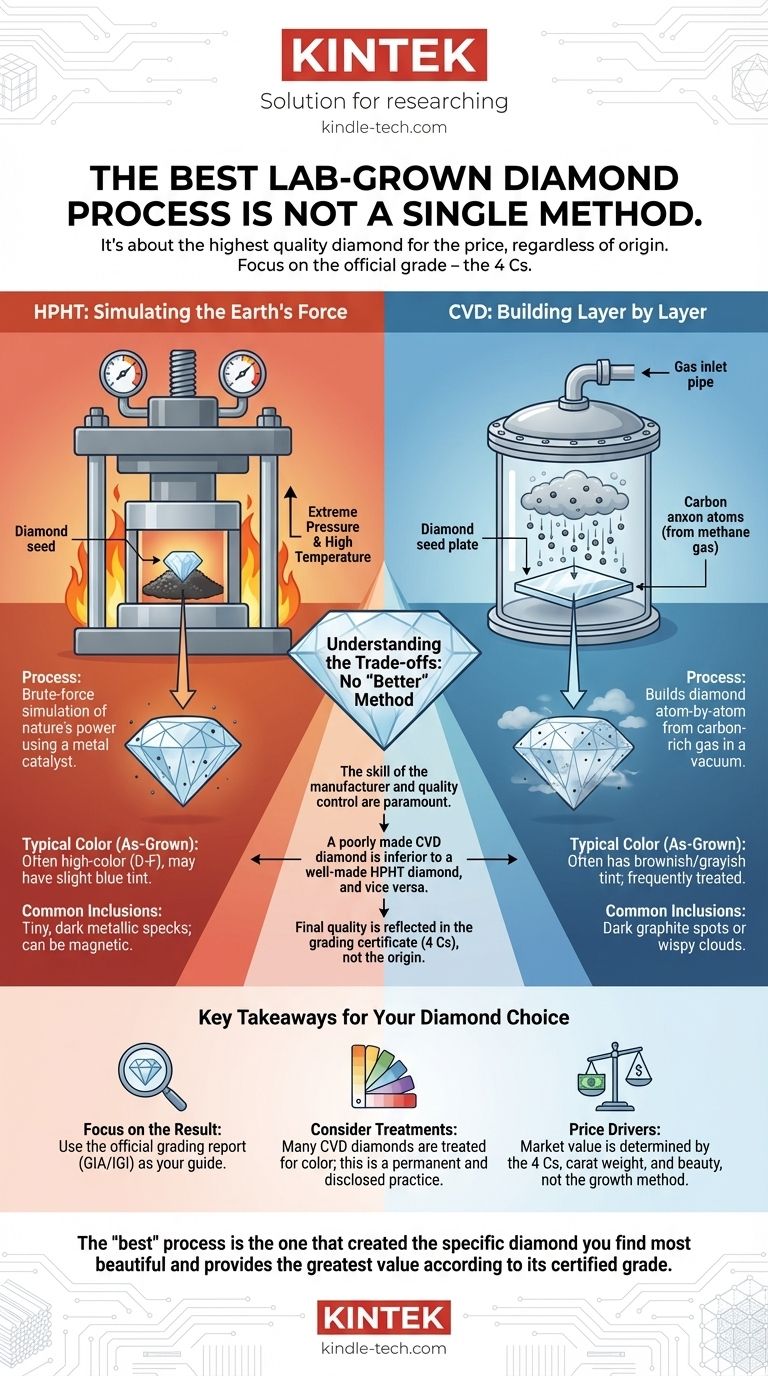

The Two Primary Growth Methods Explained

To make an informed decision, you must first understand the fundamental difference between the two primary manufacturing processes. They both produce a stone that is chemically, physically, and optically identical to a mined diamond, but they get there in very different ways.

HPHT: Simulating the Earth's Force

The High Pressure/High Temperature method is the original process for creating diamonds and most closely mimics the natural conditions deep within the Earth.

It starts with a carbon source, like graphite, which is placed in a large mechanical press. This press subjects the carbon to immense pressure and extremely high temperatures, facilitated by a metal catalyst.

Under these conditions, the carbon source dissolves and recrystallizes around a small diamond seed, forming a new, larger diamond crystal. The entire process is a brute-force simulation of nature's power.

CVD: Building Layer by Layer

Chemical Vapor Deposition is a newer technique that can be thought of as building a diamond atom-by-atom.

The process begins with a thin slice of a diamond seed placed inside a sealed vacuum chamber. The chamber is then filled with a carbon-rich gas mixture (like methane).

This gas is heated to a point where it breaks apart, allowing pure carbon atoms to "rain" down and attach to the diamond seed, slowly building up layers and growing into a larger crystal.

How the Process Impacts the Final Diamond

While the final gems are both diamonds, the different growth environments can leave subtle clues and result in different raw characteristics before cutting and polishing.

Color Characteristics

HPHT diamonds are grown in a highly controlled environment that limits impurities. As a result, they are more likely to be produced as high-color (D-F range) stones without needing further treatment. However, trace amounts of boron from the process can sometimes impart a slight blue tint.

CVD diamonds, in their raw state, often exhibit a brownish or grayish tint. Many CVD stones undergo a post-growth treatment process (often using HPHT) to remove this coloration and improve their grade, a common and fully disclosed industry practice.

Clarity and Inclusions

The defining inclusions in an HPHT diamond are often tiny, dark specks of the metallic catalyst used during its growth. These inclusions are opaque and can be magnetic, which is a key identifier for gemologists.

CVD diamonds do not use a metallic catalyst, so their inclusions are different. They typically consist of small, dark graphite spots or wispy "clouds" that are a result of variations in the crystal growth.

Understanding the Trade-offs

Choosing between HPHT and CVD is not about picking a "winner." It's about understanding the nuances of the market and the material.

The Myth of Superiority

There is no "better" method. Both processes can produce flawless, colorless diamonds of exceptional quality, and both can produce low-quality industrial material. The skill of the manufacturer and the quality control of the growth cycle are far more important than the method itself.

A poorly made CVD diamond is inferior to a well-made HPHT diamond, and vice versa. The final quality is reflected in the grading certificate, not the origin.

The Role of Post-Growth Treatments

Many lab diamonds, particularly CVD stones, are treated to improve their color. This is a permanent enhancement and must be disclosed on the grading report. A treated diamond is not "worse," but you should be aware of it. The presence of treatment does not impact the diamond's durability or brilliance.

Price and Market Perception

Years ago, there may have been market preferences or price differences between the two types. Today, the market has matured. Price is driven almost entirely by the 4 Cs, carat weight, and the resulting beauty of the stone. Reputable jewelers price their diamonds based on quality, not on the growth method.

Making the Right Choice for Your Diamond

Forget the origin story and focus on the result. Use the diamond's official grading report from a respected lab (like GIA or IGI) as your guide.

- If your primary focus is a guaranteed "as-grown" high-color stone: An untreated HPHT diamond may offer a more direct path to a colorless gem without post-growth enhancements.

- If your primary focus is finding the best balance of size and quality for your budget: Compare individual HPHT and CVD diamonds side-by-side, focusing solely on their 4 Cs, light performance, and price.

- If your primary focus is simply the best value: Ignore the growth method entirely. Your decision should be based on the diamond's certification and your personal visual preference.

Ultimately, the "best" process is the one that created the specific diamond you find most beautiful and that provides the greatest value according to its certified grade.

Summary Table:

| Aspect | HPHT Diamond | CVD Diamond |

|---|---|---|

| Process | Simulates Earth's natural conditions with high pressure & temperature. | Builds diamond atom-by-atom from a carbon-rich gas in a vacuum chamber. |

| Typical Color (As-Grown) | Often high-color (D-F), may have a slight blue tint. | Often has a brownish/grayish tint; frequently treated to improve color. |

| Common Inclusions | Tiny, dark metallic specks; can be magnetic. | Dark graphite spots or wispy clouds. |

| Key Takeaway | Quality depends on the final grade, not the method. | Quality depends on the final grade, not the method. |

Find Your Perfect Lab-Grown Diamond with KINTEK

Navigating the nuances of HPHT and CVD diamonds can be complex. The most important factor is the final quality of the stone, which is why partnering with an expert is key.

KINTEK specializes in precision equipment and consumables for advanced material synthesis, including the technologies behind these remarkable gems. Whether you are a researcher, manufacturer, or jeweler, understanding the process is crucial for quality control and innovation.

Let us help you achieve unparalleled results. Our expertise can support your quest for the highest quality diamonds, ensuring your projects meet the highest standards.

Contact our experts today to discuss how KINTEK's solutions can enhance your diamond synthesis and analysis processes.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- CVD Diamond for Thermal Management Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What are the applications of microwave plasma? From Diamond Synthesis to Semiconductor Fabrication

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How does microwave plasma work? Unlock Precision Material Synthesis for Advanced Manufacturing

- How to start a lab grown diamond business? Choose the Right Model for Success

- What is the difference between MPCVD and HFCVD? Choose the Right CVD Method for Your Application