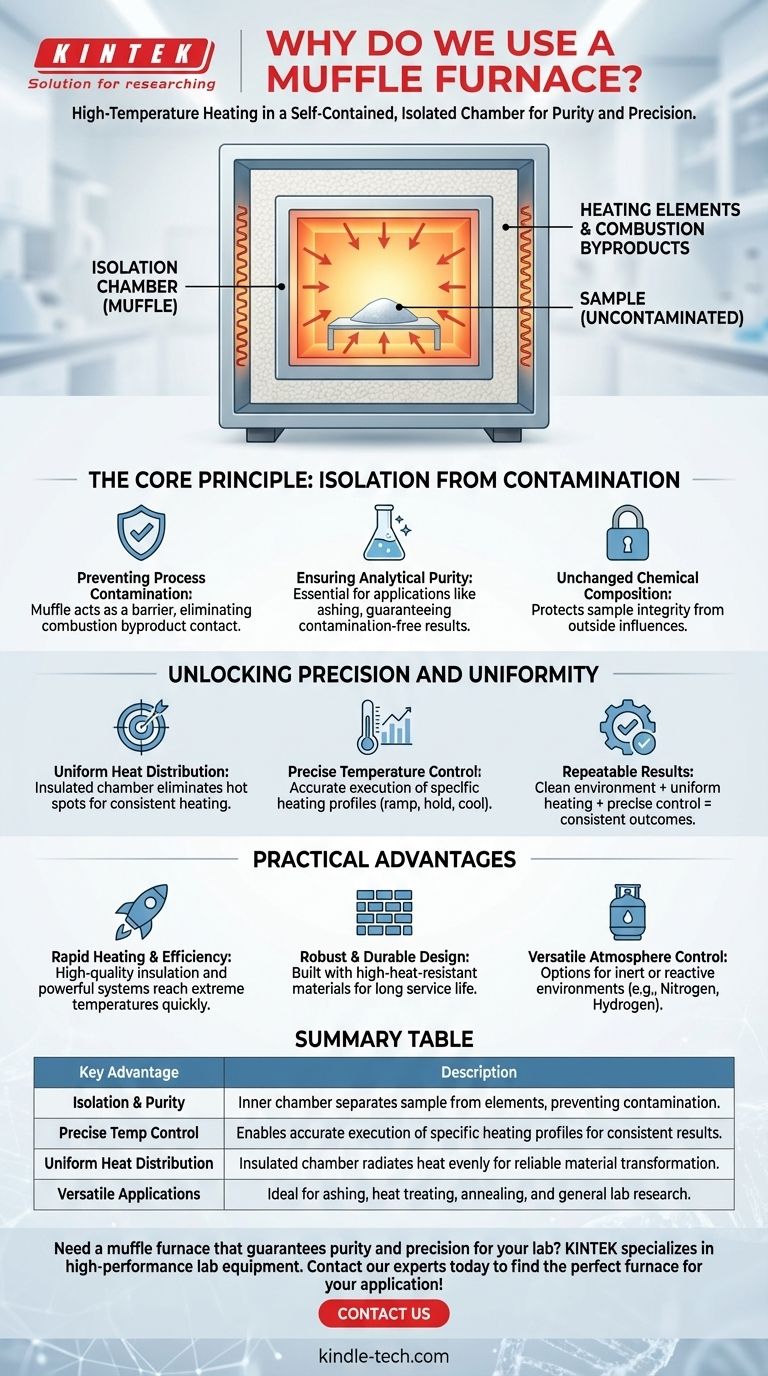

At its core, a muffle furnace is used to heat materials to very high temperatures inside a self-contained, isolated chamber. This design separates the material being heated from the actual heating elements and any potential contaminants, such as the byproducts of combustion. This isolation is the fundamental reason it is a critical tool in both laboratories and industrial settings.

The defining advantage of a muffle furnace is its inner chamber—the "muffle"—which shields a sample from direct contact with the heat source. This separation is what enables highly pure, precisely controlled, and uniformly heated conditions essential for reliable scientific and industrial work.

The Core Principle: Isolation from Contamination

The primary purpose that distinguishes a muffle furnace is its ability to create a clean heating environment. This is achieved through the design of the internal chamber.

What "Muffle" Means

The term "muffle" refers to the furnace's inner lining or chamber, which encloses the material being processed. This chamber acts as a physical barrier between the sample and the heating elements.

Preventing Process Contamination

In fuel-fired furnaces, combustion creates byproducts that can react with and contaminate a sample. A muffle furnace eliminates this risk entirely by separating the heating source from the workload, ensuring the material's chemical composition remains unchanged by outside influences.

Ensuring Analytical Purity

This isolation is non-negotiable for applications like ashing, where the goal is to burn off organic material to determine the quantity of non-combustible residue. Any contamination would invalidate the results.

Unlocking Precision and Uniformity

Beyond purity, the enclosed design of a muffle furnace allows for an exceptionally high degree of control over the heating process.

Uniform Heat Distribution

The insulated chamber is designed to radiate heat evenly from all sides. This eliminates hot spots and ensures the entire sample experiences the same temperature, which is critical for consistent results.

Precise Temperature Control

Modern muffle furnaces offer excellent temperature accuracy and stability. This allows operators to execute specific heating profiles—ramping up, holding, and cooling down at precise rates—which is essential for materials science and heat treating.

Repeatable Results

The combination of a clean environment, uniform heating, and precise control means that processes can be repeated with a high degree of confidence, yielding consistent and accurate outcomes every time.

Understanding the Practical Advantages

Muffle furnaces are valued not just for their technical precision but also for their operational efficiency and durability.

Rapid Heating and Efficiency

Thanks to high-quality insulation and powerful heating systems, muffle furnaces can reach very high temperatures (often up to 1300°C) quickly. The insulation also retains heat effectively, making them energy-efficient during operation.

Robust and Durable Design

These furnaces are built with high-heat-resistant materials to withstand extreme thermal stress over long periods. Their robust construction ensures a long service life even with frequent use.

Versatile Atmosphere Control

While basic models heat samples in air, many are designed to be used with different atmospheres. Introducing gases like nitrogen or hydrogen can create inert or specific reactive environments for advanced processes.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on the requirements of your application. A muffle furnace is the superior choice when process integrity is paramount.

- If your primary focus is analytical purity (ashing, chemical analysis): The key benefit is total isolation from contaminants, which guarantees the accuracy of your results.

- If your primary focus is material transformation (heat treating, annealing): The critical advantages are the precise temperature control and uniform heating needed to achieve specific, repeatable material properties.

- If your primary focus is general-purpose lab research: Its combination of rapid heating, efficiency, and robust design makes it a versatile and reliable workhorse for a wide range of high-temperature tasks.

Ultimately, a muffle furnace is chosen when the integrity of the sample and the precision of the heating process cannot be compromised.

Summary Table:

| Key Advantage | Description |

|---|---|

| Isolation & Purity | Inner chamber (muffle) separates sample from heating elements, preventing contamination from combustion byproducts. |

| Precise Temperature Control | Enables accurate execution of specific heating profiles (ramp, hold, cool) for consistent results. |

| Uniform Heat Distribution | Insulated chamber radiates heat evenly, eliminating hot spots for reliable material transformation. |

| Versatile Applications | Ideal for ashing, heat treating, annealing, and general lab research requiring high-temperature integrity. |

Need a muffle furnace that guarantees purity and precision for your lab? KINTEK specializes in high-performance lab equipment, including durable muffle furnaces designed for accurate temperature control and contaminant-free processing. Whether your focus is analytical chemistry, materials science, or general research, our solutions ensure reliable, repeatable results. Contact our experts today to find the perfect furnace for your application!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a muffle furnace in food analysis? A Guide to Precise Mineral Content Measurement

- What is the purpose of a muffle furnace? Achieve High-Purity Heating for Your Lab

- What is the concept of muffle furnace? Achieve Clean, Uniform High-Temperature Processing

- What is the primary characteristic of a muffle furnace? Unlock Pure, Contamination-Free Heating

- What is the difference between a box furnace and a muffle furnace? Choose the Right Lab Furnace for Your Application