In short, argon is the standard gas for sputtering because it provides the best balance of high sputtering efficiency, chemical inertness, and low cost. Its atomic mass is ideal for physically dislodging atoms from most target materials without reacting with them, ensuring a pure, high-quality deposited film.

The choice of gas in sputtering is not arbitrary; it is a critical process parameter. Argon is the industry workhorse because it is an inert, heavy, and abundant noble gas that efficiently creates a stable plasma to physically bombard a target without chemically altering the resulting film.

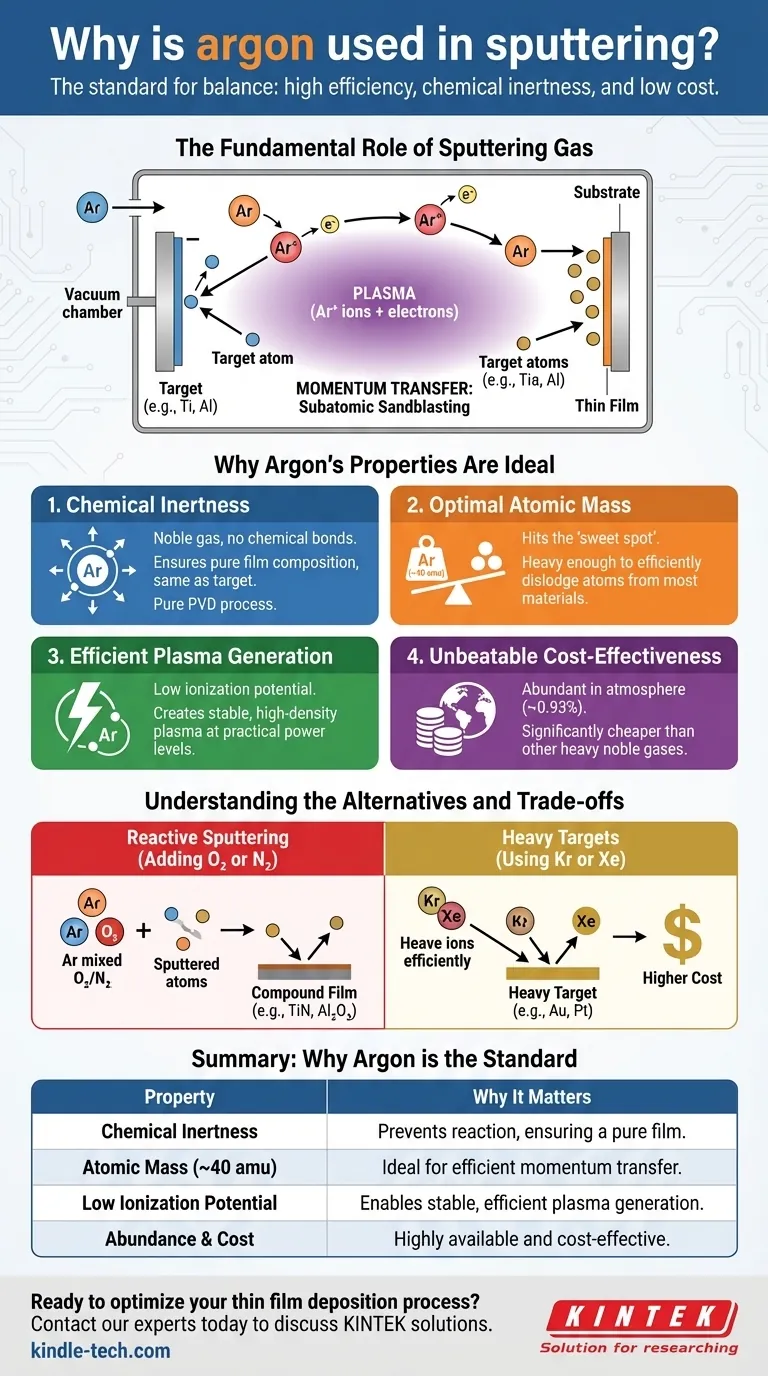

The Fundamental Role of Sputtering Gas

To understand why argon is the default choice, we must first understand the fundamental job of the gas in the sputtering process. The entire technique relies on a physical, not chemical, mechanism.

Creating the Plasma

Sputtering begins by introducing a low-pressure gas, like argon, into a vacuum chamber. An electric field is applied, which strips electrons from the gas atoms.

This process creates a glowing, ionized gas known as plasma, consisting of positively charged gas ions (Ar+) and free electrons.

The Bombardment Process

The sputtering target (the material you want to deposit) is given a negative electrical potential. This attracts the positively charged argon ions from the plasma.

These ions accelerate and collide with the target at high velocity. The impact is a pure momentum transfer, acting like a subatomic sandblaster that physically knocks atoms or molecules loose from the target surface. These ejected atoms then travel and deposit onto a substrate, forming a thin film.

Why Argon's Properties Are Ideal

Argon possesses a unique combination of characteristics that makes it exceptionally well-suited for this physical bombardment process.

1. Chemical Inertness

As a noble gas, argon is chemically inert. It does not readily form chemical bonds with other elements.

This is the most critical property. It ensures that the argon ions bombard the target and then become neutralized without reacting with the target material or the newly deposited film. The result is a film with the same chemical composition as the target—a pure physical vapor deposition (PVD) process.

2. Optimal Atomic Mass

Sputtering is about momentum transfer, where momentum is a function of mass and velocity. Argon, with an atomic mass of approximately 40 amu, hits a "sweet spot."

It is heavy enough to effectively dislodge atoms from most common engineering materials (like aluminum, titanium, silicon, and copper). Lighter gases like helium or neon would have a much lower sputtering yield, bouncing off the target inefficiently.

3. Efficient Plasma Generation

Argon has a relatively low ionization potential. This means it doesn't require an extreme amount of energy to be converted into a plasma.

This property allows for the creation of a stable, high-density plasma at practical power levels and pressures, making the process both efficient and controllable.

4. Unbeatable Cost-Effectiveness

Argon is the third most abundant gas in Earth's atmosphere (~0.93%). Its abundance makes it significantly cheaper and more readily available than the other heavy noble gases that could also be used.

Understanding the Alternatives and Trade-offs

While argon is the standard, it is not the only option. Understanding when to use other gases reveals the trade-offs inherent in the process.

Reactive Sputtering: Adding O₂ or N₂

Sometimes, the goal is to deposit a compound film, not a pure one. For materials like titanium nitride (TiN) or aluminum oxide (Al₂O₃), a reactive gas is intentionally added.

In these cases, oxygen or nitrogen is mixed with the primary argon gas. The argon still performs the physical sputtering, but the reactive gas combines with the sputtered atoms either in transit or on the substrate to form the desired compound.

Heavy Targets: Using Krypton (Kr) or Xenon (Xe)

For sputtering very heavy target materials like gold (Au) or platinum (Pt), argon's momentum transfer can be less efficient.

In these high-mass situations, heavier noble gases like krypton (Kr) or xenon (Xe) can provide a higher sputtering yield. The trade-off is a dramatic increase in cost, limiting their use to specialized applications where maximum deposition rate is the top priority.

Making the Right Choice for Your Goal

The gas you choose is a direct lever for controlling the outcome of your deposition process. Base your decision on the specific properties you need in your final thin film.

- If your primary focus is depositing a pure elemental or alloy film: Argon is almost always the correct choice due to its inertness, efficiency, and low cost.

- If your primary focus is creating a specific compound film (an oxide or nitride): Use a mixture of argon as the sputtering gas and a small percentage of a reactive gas (O₂, N₂) to control the film's stoichiometry.

- If your primary focus is maximizing the deposition rate of a heavy element like gold or tungsten: Consider using krypton or xenon, but only if the significant increase in gas cost is justifiable for your project.

Ultimately, understanding the role of argon is the first step toward mastering the control and precision offered by the sputtering technique.

Summary Table:

| Property | Why It Matters for Sputtering |

|---|---|

| Chemical Inertness | Prevents reaction with target material, ensuring a pure film. |

| Atomic Mass (~40 amu) | Ideal for efficient momentum transfer to dislodge target atoms. |

| Low Ionization Potential | Enables stable, efficient plasma generation at practical power levels. |

| Abundance & Cost | Highly available and cost-effective compared to alternatives like Kr or Xe. |

Ready to optimize your thin film deposition process? The right sputtering gas is critical for achieving the purity, efficiency, and quality your research demands. At KINTEK, we specialize in providing high-performance lab equipment and consumables tailored to your laboratory's specific sputtering and PVD needs.

Contact our experts today to discuss how our solutions can enhance your results and streamline your workflow.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition