A muffle furnace gets its name directly from its core component: the "muffle." This is a specialized chamber made of high-temperature, insulating material that separates the substance being heated from the actual heat source. This design ensures the sample is heated uniformly and without any contamination.

The term "muffle" signifies the furnace's fundamental design principle of indirect heating and isolation. This separation protects the sample from contaminants while the chamber's insulation allows for stable, energy-efficient, and high-temperature operation.

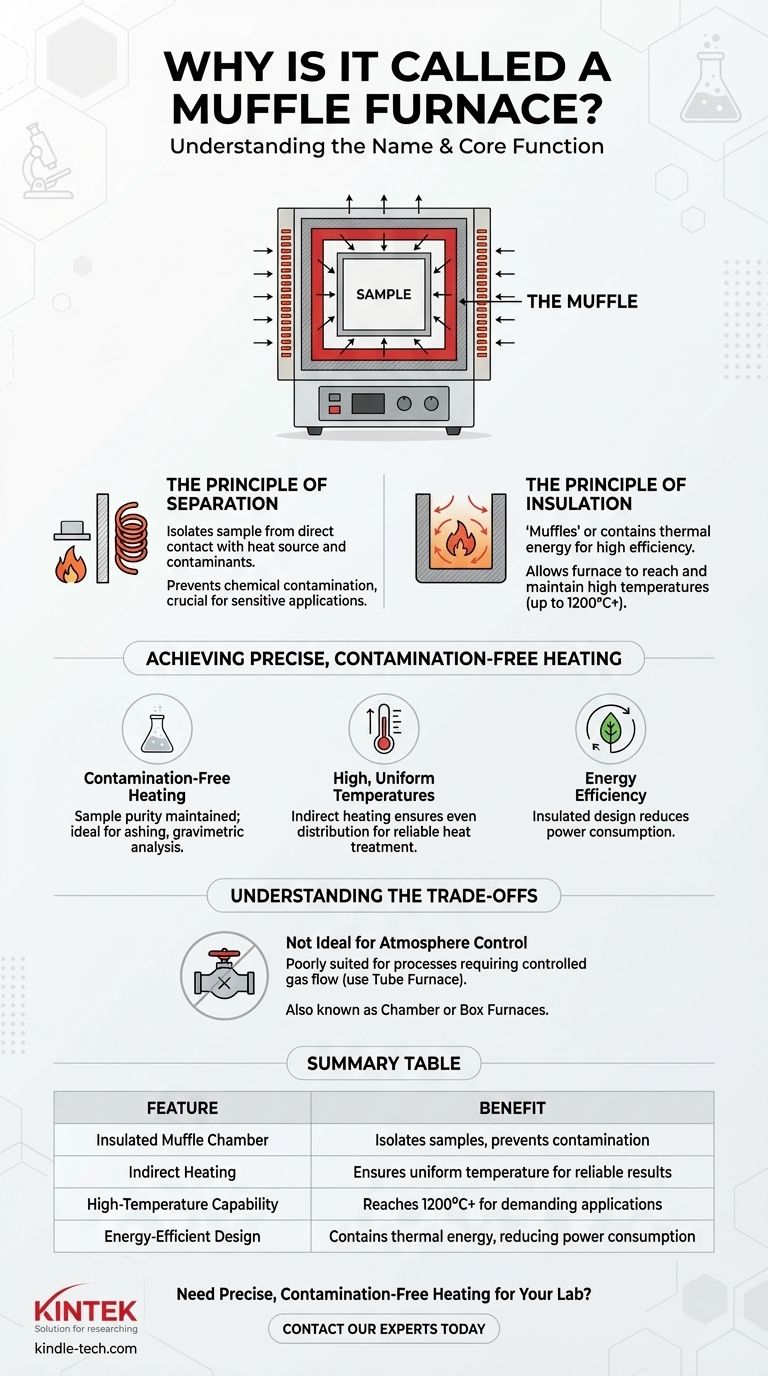

What "Muffle" Means in Practice

The muffle is not just a box; it's the defining feature that dictates how the furnace works. Its role is best understood through two core principles.

The Principle of Separation

Historically, the muffle was a sealed enclosure that separated a sample from the flames and combustion byproducts of a fuel-based heat source. This prevented chemical contamination.

In modern electric furnaces, this principle of separation still applies. The muffle isolates the sample from direct contact with the heating coils and any external atmospheric contaminants.

The Principle of Insulation

The muffle is constructed from thick, insulating materials. In today's designs, high-temperature heating coils are placed within this insulating material.

This arrangement essentially "muffles" or contains the thermal energy. It prevents heat from escaping, which is critical for reaching very high temperatures and maintaining them efficiently.

How This Design Defines Its Purpose

The unique construction of a muffle furnace makes it a standard piece of equipment for precise laboratory work where heat purity and stability are paramount.

Achieving Contamination-Free Heating

Because the sample never touches the heating elements or combustion gases, its chemical purity is maintained.

This is essential for sensitive applications like ashing organic matter, gravimetric analysis, or the alkali melting of minerals, where any external substance would corrupt the results.

Reaching High, Uniform Temperatures

The insulated chamber is exceptionally good at trapping heat, allowing the furnace to reach temperatures up to 1200°C or higher.

The indirect heating method ensures this heat is distributed evenly throughout the chamber, providing the temperature uniformity required for reliable material heat treatment.

Ensuring Energy Efficiency

By preventing heat from escaping, the muffle design makes the furnace highly energy-efficient. It can reach and hold high temperatures without consuming excessive power.

Understanding the Trade-offs

While powerful, the muffle furnace design is not universal. Understanding its inherent limitations is key to using it correctly.

Not Ideal for Atmosphere Control

The sealed, insulated nature of the muffle chamber makes it poorly suited for processes that require a controlled flow of gas.

If your work involves reactions under a specific atmosphere (like nitrogen or argon), a specialized tube furnace is a more appropriate choice.

Alternative Names Can Cause Confusion

Muffle furnaces are often referred to as chamber furnaces or box furnaces. While these names describe its shape, they don't capture the essential functional role of the muffle itself.

Making the Right Choice for Your Goal

Selecting the right heating equipment depends entirely on your specific scientific or industrial objective.

- If your primary focus is material purity and analysis: A muffle furnace is the correct choice for processes like ashing or gravimetric analysis where avoiding contamination is non-negotiable.

- If your primary focus is high-temperature heat treatment: Its ability to create a stable, uniform, and high-heat environment is perfect for processes like annealing or calcination.

- If your primary focus is reactions in a controlled gas environment: You should use a tube furnace or another system specifically designed for gas passage and atmosphere control.

Ultimately, the name "muffle furnace" perfectly describes its core function: to provide pure, intense, and contained heat.

Summary Table:

| Feature | Benefit |

|---|---|

| Insulated Muffle Chamber | Isolates samples from heat source, preventing contamination |

| Indirect Heating | Ensures uniform temperature distribution for reliable results |

| High-Temperature Capability | Reaches temperatures up to 1200°C+ for demanding applications |

| Energy-Efficient Design | Contains thermal energy, reducing power consumption |

Need precise, contamination-free heating for your lab?

At KINTEK, we specialize in high-performance muffle furnaces designed for critical applications like ashing, gravimetric analysis, and material heat treatment. Our equipment ensures the purity and temperature uniformity your research demands.

Contact our experts today to find the perfect muffle furnace for your laboratory's specific needs and discover how KINTEK can enhance your workflow with reliable, energy-efficient lab equipment.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the factors that affect melting? Master Temperature, Pressure & Chemistry for High-Quality Results

- What do you use a muffle furnace for? Achieve Contamination-Free High-Temperature Processing

- What is the application of a muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What are the components of a muffle furnace? Unlock the Core Systems for Precise, Safe Heating

- Does heat capacity affect melting point? Unraveling the Key Differences in Thermal Properties