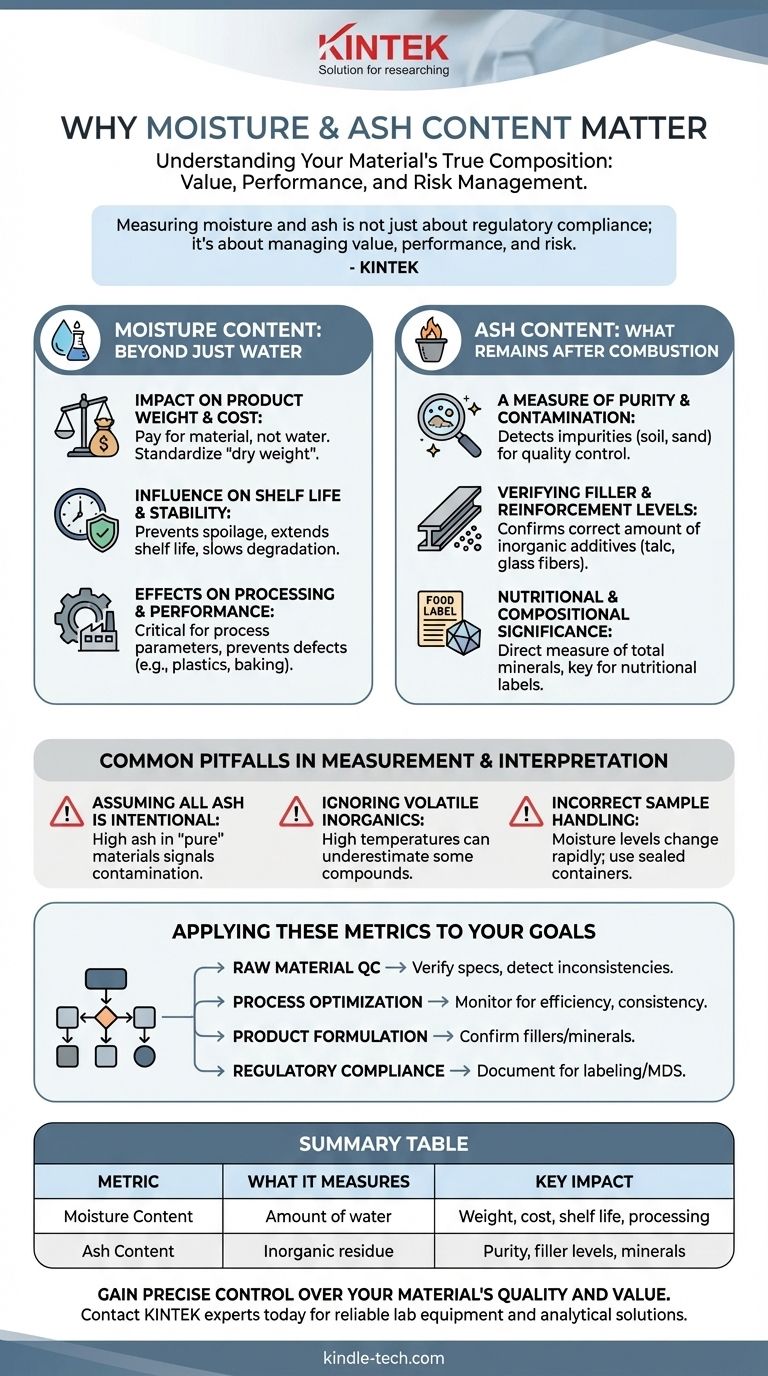

At its core, analyzing moisture and ash content is about understanding what your material is truly made of. Moisture content quantifies the amount of water, which affects a product's weight, stability, and processing behavior. Ash content measures the non-combustible, inorganic material remaining after burning, which serves as a critical indicator of purity, filler content, or contamination. Together, they form a foundational quality check for countless materials.

Measuring moisture and ash is not just about regulatory compliance; it's about managing value, performance, and risk. Moisture content directly impacts the concentration and economic value of your material, while ash content provides a clear proxy for purity, mineral composition, and the presence of inert fillers.

The Role of Moisture Content: Beyond Just Water

Moisture analysis is one of the most common tests performed because water content has far-reaching implications for both financial and physical product characteristics.

Impact on Product Weight and Cost

When you purchase raw materials, you are often paying by weight. If a material has a high moisture content, you are effectively paying for water instead of the active or valuable component.

Consistent moisture testing ensures you receive what you paid for and helps standardize the "dry weight" basis for product formulations.

Influence on Shelf Life and Stability

Water is a key enabler of microbial growth, such as mold and bacteria. In foods, pharmaceuticals, and biomass, controlling moisture content is essential for preventing spoilage and extending shelf life.

Excess moisture can also accelerate chemical degradation, causing changes in texture, color, and efficacy over time.

Effects on Processing and Performance

Many manufacturing processes are highly sensitive to moisture. In plastics, too much moisture can cause voids and surface defects during extrusion or molding.

In baking or chemical synthesis, precise water levels are often a critical reaction parameter, and deviations can lead to failed batches and inconsistent product quality.

The Role of Ash Content: What Remains After Combustion

Ash testing involves burning off all organic matter at high temperatures to isolate the inorganic residue. What's left behind tells a crucial story about the material's origin and composition.

A Measure of Purity and Contamination

In materials like flour, spices, or biofuels, high ash content can indicate contamination from soil, sand, or other inorganic impurities. It serves as a simple but effective test for cleanliness and raw material quality.

Verifying Filler and Reinforcement Levels

In the plastics and polymer industry, inorganic materials like talc, calcium carbonate, or glass fibers are intentionally added as fillers or reinforcing agents.

Ash testing is the definitive method to verify that the correct percentage of this inorganic filler is present in the final product, ensuring it meets performance specifications for strength, rigidity, or cost.

Nutritional and Compositional Significance

In food science, ash content is a direct measure of the total amount of minerals in a product. This is a key component of proximate analysis used for creating nutritional labels.

For materials like coal or biomass, low ash content is desirable as ash does not contribute to energy production and can cause fouling and slagging in boilers.

Common Pitfalls in Measurement and Interpretation

While these tests are fundamental, their results can be misleading if the context is not understood. Accurate interpretation requires awareness of common challenges.

Assuming All Ash is Intentional Filler

In composite materials, a high ash value is expected. However, in "pure" materials, a higher-than-expected ash content almost always signals a problem with contamination or adulteration.

Ignoring Volatile Inorganics

Standard ash tests use very high temperatures (often 550-900°C). Some inorganic compounds can partially vaporize or decompose at these temperatures, leading to an underestimation of the true inorganic content.

Incorrect Sample Handling

Moisture content is not static. A sample's moisture level can change rapidly when exposed to ambient air. Proper sample collection, storage in sealed containers, and prompt analysis are critical for obtaining accurate results.

Applying These Metrics to Your Goals

Your reason for testing will determine how you use the data. The key is to connect the measurement directly to a specific quality or performance outcome.

- If your primary focus is raw material quality control: Use moisture and ash tests to verify supplier specifications and detect inconsistencies before they enter your production process.

- If your primary focus is process optimization: Monitor moisture content to adjust operational parameters like drying time or temperature, ensuring consistent output and energy efficiency.

- If your primary focus is product formulation (e.g., plastics or food): Use ash content to confirm that the correct amount of mineral filler or nutritional minerals is present in the final product.

- If your primary focus is regulatory compliance: Document moisture and ash values as part of the proximate analysis required for nutritional labeling or material data sheets.

By mastering the measurement of what can be removed and what remains, you gain fundamental control over your material's value, quality, and performance.

Summary Table:

| Metric | What It Measures | Key Impact |

|---|---|---|

| Moisture Content | Amount of water in a material | Weight, cost, shelf life, and processing behavior |

| Ash Content | Non-combustible inorganic residue | Purity, filler levels, contamination, and mineral composition |

Gain precise control over your material's quality and value. Accurate moisture and ash content analysis is fundamental for consistent product formulation, cost management, and regulatory compliance. KINTEK specializes in providing reliable lab equipment and consumables for all your analytical testing needs. Contact our experts today to find the perfect solution for your laboratory.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do you perform calcination? Master Precise Thermal Treatment for Your Materials

- What is the effect of calcination? Unlock Material Transformation for Industrial Processes

- What is the effect of calcination temperature on the properties of nanoparticles? Master the Trade-Off for Optimal Performance

- What is ashing in a muffle furnace? Isolate Inorganic Content with Precision

- What is dry ashing in a muffle furnace? A Guide to Precise Mineral Analysis